Porozumění tvorbě syntetických vláken

Nylon a polyamid jsou základní syntetická vlákna, která způsobila revoluci v textilním průmyslu. Tyto materiály jsou známé svou všestranností, pevností a trvanlivostí a nacházejí uplatnění od oděvů a obuvi až po automobilové díly a zdravotnické prostředky. Tento článek se zabývá složitými chemickými procesy, které se podílejí na přeměně výchozích monomerů na tyto základní polymery.

Získávání monomerů pro výrobu nylonu

Výroba nylonu začíná syntézou jeho klíčových monomerů. Základními chemickými látkami jsou kyselina adipová a hexamethylenediamin (HMDA). Kyselina adipová vzniká oxidací cyklohexanu, zatímco HMDA se vyrábí reakcí mezi amoniakem a formaldehydem. Tyto dva monomery se pak spojí v exotermické reakci, kterou usnadňuje katalyzátor, jako je oktoát cínatý, za vzniku polymeru charakterizovaného opakujícími se amidovými vazbami mezi jednotkami kyseliny adipové a HMDA.

Syntéza polyamidů a polymerace meziproduktů

Polyamid, zejména nylon 6,6, se řídí poněkud odlišnou cestou syntézy. Ačkoli jako stavební bloky využívá rovněž kyselinu adipovou a hexamethylen-diamin, tyto monomery nejsou přímo polymerizovány společně. Místo toho se každý z nich nejprve polymerizuje samostatně za vzniku mezipolymerů. Tyto meziprodukty jsou následně zreagovány dohromady a vytvořením amidových vazeb vzniká konečný polymer. Tímto procesem vzniká polymer s opakující se jednotkou kyseliny adipové a HMDA, podobný nylonu, ale dosažený odlišnou cestou.

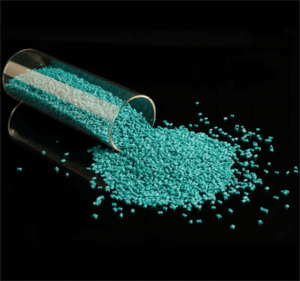

Extrudování polymerů do vláken

Po přeměně monomerů na polymery následuje vytlačování vláken. To se běžně provádí pomocí taveninového zvlákňování. Při tomto procesu se polymer zahřívá, dokud nezkapalní, a poté se protlačuje spinnerem, aby se vytvořila jemná vlákna. Tato vlákna se rychle ochladí a ztuhnou buď ponořením do vodní lázně, nebo ochlazením na vzduchu, čímž vzniknou pevná, pružná vlákna připravená k dalšímu zpracování.

Ošetření po odstředění pro zlepšení vlastností vláken

Po vytlačování se vlákna různě upravují, aby se zlepšily jejich vlastnosti. Pro snížení tření v dalších fázích zpracování mohou být použita maziva, zatímco pro dodání požadovaných barev se přidávají barviva. Další povrchové úpravy mohou být použity ke zlepšení trvanlivosti vláken nebo k dodání specifických vlastností, jako je odolnost proti skvrnám nebo vodoodpudivost, díky čemuž jsou vlákna vhodná pro širokou škálu aplikací.

Závěr: Budoucnost výroby syntetických vláken

Cesta od monomerů k finálnímu polymeru při výrobě nylonu a polyamidu zahrnuje řadu složitých chemických reakcí. Výsledná vlákna, známá svou odolností a univerzálností, mají zásadní význam pro mnoho průmyslových odvětví. S pokračujícím technologickým pokrokem slibuje vývoj nových metod výroby těchto materiálů další rozšíření jejich potenciálních aplikací a upevnění jejich role jako nepostradatelných součástí jak v každodenních výrobcích, tak v pokročilých technologických inovacích.

Často kladené dotazy o nylonu a polyamidu

1.Co je to nylon a polyamid a čím se liší?

Nylon a polyamid jsou syntetické polymery běžně používané v textilu a v různých průmyslových aplikacích. Termín "nylon" označuje specifický typ polyamidu, obvykle nylon 6 nebo nylon 6,6, který je známý svou vysokou pevností, pružností a odolností proti oděru. Polyamid je širší kategorie, která zahrnuje různé typy polymerů vyrobených z opakujících se jednotek spojených amidovými vazbami, neomezuje se pouze na nylon.

2. Jaké je hlavní použití nylonu a polyamidu?

Nylonová a polyamidová vlákna se díky své odolnosti a všestrannosti používají v mnoha aplikacích. Mezi běžná použití patří:

- Textil:Oděvy, punčochové zboží a sportovní oblečení.

- Obuv:Svršky a tkaničky obuvi.

- Automobilový průmysl:Díly jako sací potrubí, koncové nádrže chladiče a převodovky.

- Zdravotnické prostředky:Šití a další lékařské komponenty.

- Průmyslové aplikace:Lana, rybářské sítě a dopravníkové pásy.

3. Jak se vyrábí monomery pro nylon?

Pro výrobu nylonu jsou klíčovými monomery kyselina adipová a hexamethylenediamin (HMDA):

- Kyselina adipovávzniká oxidací cyklohexanu, při níž se jako oxidační činidlo používá kyselina dusičná nebo vzduch.

- HMDAse syntetizuje reakcí amoniaku a formaldehydu prostřednictvím řady chemických reakcí zahrnujících hydrogenaci a cyklohexanon.

Tyto monomery jsou poté polymerizovány kondenzační reakcí za vzniku nylonu.

4. Co je taveninové předení a jak se používá při výrobě vláken?

Tavné spřádání je proces používaný k výrobě vláken z polymerů, jako je nylon a polyamid. Polymer se zahřívá, dokud se neroztaví, a poté se protlačuje malými otvory v zařízení zvaném spinneret. Jakmile tekutý polymer opustí spinneret, ochladí se a ztuhne do jemných vláken. Tato vlákna se pak dále natahují a ochlazují, aby se zvýšila jejich pevnost a pružnost.

5. Proč se nylonová a polyamidová vlákna po spřádání upravují?

Úpravy po spřádání jsou zásadní pro zlepšení vlastností vláken a jejich přípravu pro specifické použití. Úpravy mohou zahrnovat:

- Mazání:Ke snížení tření při tkaní nebo pletení.

- Barvení:Přidání barvy do vláken.

- Dokončovací práce:Zlepšení vlastností, jako je trvanlivost, odolnost proti skvrnám nebo vodoodpudivost, díky čemuž jsou vlákna vhodnější pro konkrétní aplikace.

6. Jsou s výrobou nylonu a polyamidu spojeny obavy o životní prostředí?

Ano, existuje několik obav o životní prostředí:

- Náročnost na zdroje:Výroba nylonu a polyamidu vyžaduje značné množství energie a vody.

- Chemické emise:Procesy zahrnují nebezpečné chemické látky, které mohou při nesprávném zacházení představovat riziko pro životní prostředí.

- Nerozložitelnost:Oba materiály nejsou snadno biologicky odbouratelné, což přispívá k dlouhodobému odpadu v životním prostředí.

V současné době probíhá úsilí o vývoj udržitelnějších výrobních metod a o účinnou recyklaci těchto polymerů.

7. Jaké pokroky se dějí ve výrobě nylonu a polyamidu?

Nejnovější pokroky se zaměřují na udržitelnost a zlepšení výkonu:

- Biomateriály:Probíhá výzkum zaměřený na výrobu nylonu a polyamidu z obnovitelných zdrojů, čímž se snižuje závislost na fosilních palivech.

- Recyklační techniky:Vyvíjejí se inovativní metody recyklace nylonu a polyamidu, které vytvářejí oběhový cyklus těchto materiálů.

- Vylepšené vlastnosti:Nové receptury a výrobní postupy zvyšují pevnost, trvanlivost a pružnost těchto vláken a rozšiřují jejich aplikační potenciál.

8. Jak mohou spotřebitelé rozlišit nylon a jiné polyamidy ve výrobcích?

I když spotřebitelé nemusí být vždy schopni rozlišit nylon od jiných polyamidů pouhým pohledem, na etiketách výrobků je často uveden typ použitého vlákna. Například na visačkách oděvů může být uvedeno "nylon" nebo "polyamid" ve složení materiálu. Kromě toho jsou s nylonem běžně spojovány specifické vlastnosti, jako je vysoká pevnost, pružnost a odolnost proti oděru.

9. Jak mohu pečovat o výrobky z nylonu nebo polyamidu?

Správná péče může prodloužit životnost nylonových a polyamidových výrobků:

- Mytí:Používejte jemné prací prostředky a studenou vodu, abyste zabránili poškození a zachovali pružnost.

- Sušení:Vhodnější je sušení na vzduchu. Pokud používáte sušičku, zvolte nízkou teplotu, abyste zabránili smrštění nebo roztavení.

- Žehlení:Používejte nízkou teplotu, aby nedošlo k poškození vláken.

- Skladování:Skladujte na chladném a suchém místě mimo dosah přímého slunečního záření, aby nedošlo k degradaci materiálu.

10. Lze nylon a polyamid recyklovat?

Ano, nylon a polyamid lze recyklovat. Proces recyklace je však ve srovnání s jinými materiály složitější, a to kvůli jejich silným a odolným vlastnostem. Pokročilé chemické recyklační procesy mohou tyto polymery rozložit na jejich monomery pro opětovné použití v nových výrobcích, což podporuje udržitelnější životní cyklus těchto materiálů.

11. Jakých inovací se v budoucnu dočkáme u nylonu a polyamidu?

Mezi budoucí inovace mohou patřit:

- Ekologická výroba:Vývoj ekologičtějších procesů, které snižují dopad na životní prostředí.

- Vylepšené vlastnosti vláken:Vytváření vláken s vynikajícími vlastnostmi pro specializované aplikace.

- Chytré textilie:Integrace technologie do nylonových a polyamidových tkanin pro použití v nositelné elektronice a citlivých oděvech.

Tyto pokroky pravděpodobně rozšíří možnosti použití a zlepší udržitelnost nylonových a polyamidových materiálů.

12. Existují nějaké zdravotní problémy spojené s nošením nylonu nebo polyamidu?

Obecně jsou nylon a polyamid považovány za bezpečné pro nošení. U některých osob se však může vyskytnout citlivost pokožky nebo alergické reakce. Doporučuje se nosit výrobky z renomovaných zdrojů a dodržovat pokyny k péči, aby byla zachována bezpečnost a pohodlí vláken.