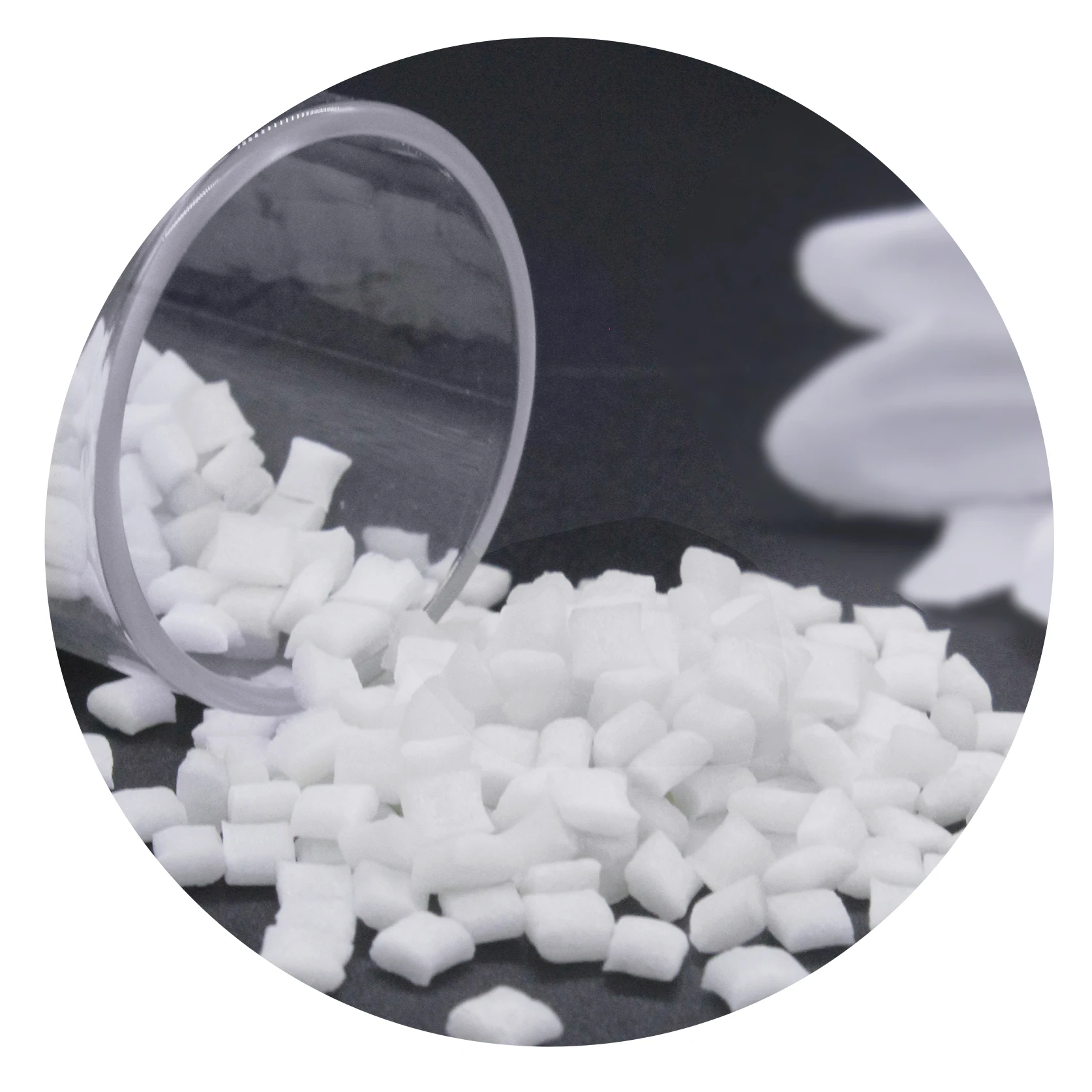

Reliable Nylon Granules Manufacturer

Fuchun New Materials Technology Co., Ltd. is a leading nylon granules manufacturer specializes in the production of different kinds of nylon such as PA11, PA12, PA6, PA66, PA610, and PA612. Founded in 2011, we have 100 workers, 15 engineers and covers a the factory of 5000 square meters.

We source our raw materials from world-renowned chemical companies such as DuPont, Asahi Kasei, Lanxess, and EMS, ensuring that our products meet the highest standards of quality and consistency.

Why Choose Fuchen?

Enhanced Strength and Flexibility for Applications

Emphasize the balance of strength and flexibility in your nylon. This allows for the creation of parts that can handle stress and strain without becoming brittle.

High-end Nylon Granules for Durable Products

Highlight the durability of your nylon granules. Strong nylon parts resist wear and tear, making them ideal for long-lasting applications across various industries.

Precision Manufacturing for Consistent Quality

Address the importance of consistent quality in nylon granules. Your manufacturing ensures that each batch performs uniformly, leading to reliable products.

Conclude by offering customization

You can provide nylon grades with specific properties (heat resistance, chemical resistance, flame retardance, etc.) to perfectly match a client’s application needs.

Get Your Custom Nylon Granules

Fuchen is a trusted nylon granules manufacturer with years of experience in creating high-quality plastic solutions for various industries. It specializes in manufacturing high-quality custom nylon granules to cover various needs of customers. Here are your custom selections:

Get A free quoteNylon Granules Benefits

Nylon granules are the raw material used to produce a wide variety of nylon products. They offer several benefits over other materials, including:

- Strength and durability:Nylon is known for its high tensile strength, making it resistant to wear and tear.

- Lightweight: Nylon is much lighter than metals, but still offers good strength.

- Versatility: Nylon granules can be easily melted and molded into a wide variety of shapes and sizes.

- Heat resistance: Nylon has a relatively high melting point, making it resistant to heat.

- Chemical resistance: Nylon is resistant to many chemicals, including oils, greases, and alkalis.

- Low friction: Nylon has a low coefficient of friction, which means that it slides easily against other surfaces.

- Cost-effective: Nylon granules are a relatively inexpensive material, making them a good choice for mass production.

Nylon Granules Application

Nylon granules, due to their versatility and range of properties, have applications in a vast number of industries. Here are examples

Automotive Industry

Nylon granules are used to manufacture a variety of automotive parts, including bumpers, dashboards, interior trim panels, fan shrouds, and carpet fibers. They are lightweight yet strong, and can withstand abrasion and wear.

Electrical and Electronics Industry

Due to its good insulating properties, nylon is used in various electrical and electronic applications such as circuit boards, connectors, wire insulation, and housing for electronic devices.

Construction Industry

Nylon granules are used to manufacture plastic lumber, flooring underlays, pipes, conduits, and door hardware. They offer good weather resistance, chemical resistance, and abrasion resistance.

Textiles and Apparel Industry

Nylon is a popular fiber used in clothing, carpets, and other textiles. Nylon granules are melted and spun into fibers to create fabrics that are strong, durable, and wrinkle-resistant.

What Our Other Customers Say About Fuchen

After-Sales Support

1. Technical Assistance:

Reputable manufacturers should have a team of technical experts available to answer your questions about the nylon granules, their properties, and their suitability for your application. This could involve guidance on processing techniques, troubleshooting issues, or recommending the right grade of nylon for your needs.

2. Material Safety Data Sheets (MSDS):

These documents provide important information about the safe handling and storage of nylon granules, including potential hazards and recommended precautions.

3. Returns and Replacements:

In case you receive a defective shipment or the granules don’t meet the specifications, some manufacturers may offer returns or replacements. Their policy will likely be outlined in their terms and conditions.

4. Ask about after-sales support during the buying process

Don’t hesitate to inquire about the specific after-sales services offered by the manufacturer before making a purchase.

Our Partner

Nylon Granules FAQs

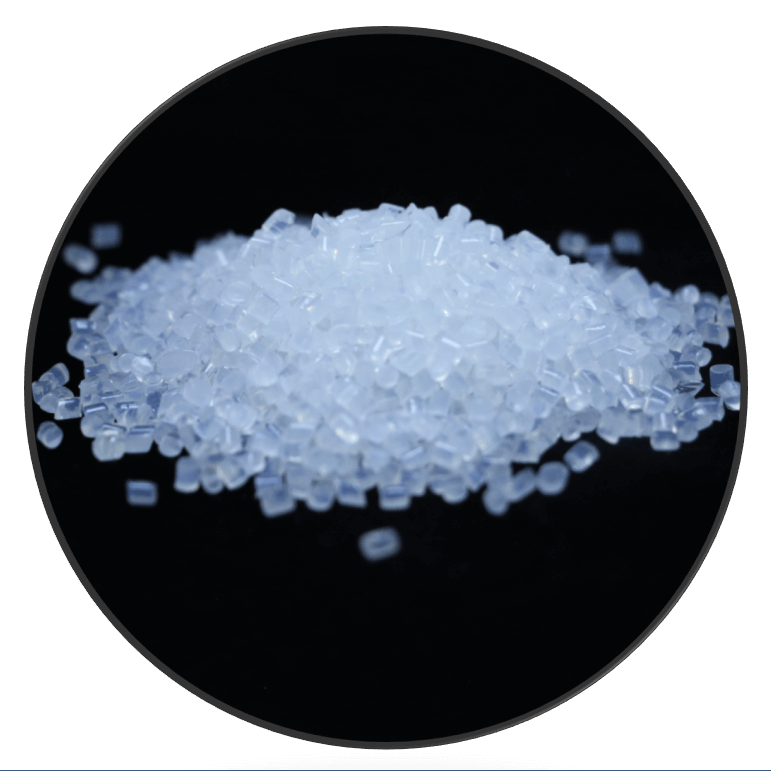

Nylon granules are the raw material form of nylon, a popular and versatile plastic material. They are small, solid pellets that can be melted and shaped into various end products.

There are several types of nylon granules, each with slightly different properties. Some common types include:

- Nylon 6: Known for its high tensile strength and wear resistance.

- Nylon 66: Offers good balance of strength, stiffness, and abrasion resistance.

- Nylon 11: Shows excellent chemical resistance and high melting point.

- Nylon 12: It has excellent dimensional stability and is often used in gears, bearings, and wear parts.

- Nylon 610: This nylon offers good mechanical strength, chemical resistance, and low moisture absorption.

- Nylon 612:It offers good impact resistance, low friction, and high abrasion resistance.

Nylon granules have a wide range of applications due to their versatility. Here are some examples:

- Textiles: Fibers for clothing, carpets, and upholstery.

- Engineering: Parts for automotive and industrial uses.

- Consumer goods: Gears, electrical connectors, buttons, zippers, etc.

- Packaging: Films and wraps for food and other products.

Nylon granules are melted using a process called extrusion or injection molding. The molten plastic is then shaped into the desired form using molds or dies.

Generally, nylon granules are safe to handle. However, as with any plastic material, it’s important to follow proper handling procedures to avoid inhalation of dust or fumes during processing.

Sustainability is a growing concern in the plastics industry. There are efforts to develop bio-based nylon alternatives and implement closed-loop systems to reduce waste from nylon granule production.