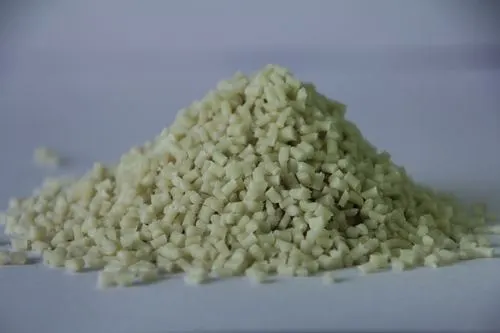

Reinforced polyamide, a composite material, merges the advantageous properties of polyamide with reinforcing agents like fiberglass or carbon fiber. This fusion results in a material that excels in various automotive applications. Its unique characteristics make it indispensable for numerous components within vehicles, contributing significantly to modern automotive engineering.

Zavedenie Zosilnený polyamid

In the constantly evolving automotive industry, materials that can offer superior performance, durability, and cost-effectiveness are in high demand. Reinforced polyamide, with its enhanced properties, has emerged as a go-to solution for many automotive components. Combining the inherent qualities of polyamide with reinforcing agents like fiberglass or carbon fiber, this composite material meets the rigorous demands of automotive engineering, making it a pivotal choice in the manufacturing of numerous vehicle parts.

Enhanced Mechanical Properties with Zosilnený polyamid: Strength and Stability

One of the standout features of reinforced polyamide is its improved mechanical properties. The addition of reinforcing agents such as fiberglass or carbon fiber significantly boosts the tensile strength, stiffness, and impact resistance of polyamide. This makes it an ideal material for components that must endure significant mechanical stress and impacts during vehicle operation. Moreover, it provides excellent thermal stability and resists degradation under high temperatures and aggressive environmental conditions, making it robust enough for a variety of demanding applications.

Engine Components with Zosilnený polyamid: Thermal Stability and Chemical Resistance

It is particularly well-suited for engine components. Its high thermal stability and resistance to oil and coolant make it an excellent choice for parts like oil pan covers, water pump housings, and fuel tank components. These properties also make it suitable for engine mounts and suspension components, where it contributes to increased rigidity and stability. The material’s ability to maintain its integrity under thermal and chemical stress ensures long-lasting performance in critical engine systems.

Electrical and Electronic Applications with Zosilnený polyamid: Insulation and Durability

In the realm of vehicle electronics, reinforced polyamide shines due to its excellent electrical insulation properties and resistance to temperature variations. It is commonly used in the manufacturing of wire harnesses, electrical connectors, and battery trays. The material’s chemical resistance and robustness against harsh environments also make it ideal for fuel injection systems and emission control components, ensuring reliable performance in sensitive electrical systems.

Interior Components with Zosilnený polyamid: Aesthetic and Functional Versatility

Inside the vehicle, reinforced polyamide finds extensive use in various interior components. Its superior impact resistance and ability to achieve a high-quality surface finish make it perfect for dashboard components, door panels, and other interior trim pieces. Additionally, its durability under repeated handling and exposure to temperature changes makes it a suitable material for automotive seating systems, offering both aesthetic appeal and functional reliability.

Durability and Performance with Zosilnený polyamid: A Comprehensive Advantage

It significantly enhances the durability and reliability of automotive components. Its improved mechanical properties and resistance to environmental factors lead to longer-lasting parts and lower maintenance costs. Additionally, the lightweight nature of reinforced polyamide contributes to better fuel efficiency and overall vehicle performance, making it a strategic choice for automakers aiming to improve both the performance and efficiency of their vehicles.

Záver Zosilnený polyamid

In summary, reinforced polyamide stands out as a versatile and economically viable solution for a wide array of automotive applications. Its enhanced mechanical properties, coupled with its thermal stability and resistance to harsh conditions, make it a preferred material for diverse components in modern vehicles. From engine and electronic systems to interior parts, the application of reinforced polyamide is crucial in enhancing the performance, durability, and reliability of today’s automotive technologies. As the automotive industry continues to evolve, the role of reinforced polyamide in advancing vehicle performance and efficiency is set to grow even more significant.

FAQ of Reinforced Polyamide

Q1: What is reinforced polyamide, and why is it important in the automotive industry?

- It is a composite material that combines polyamide with reinforcing agents like fiberglass or carbon fiber. It is important in the automotive industry due to its enhanced mechanical properties, including increased strength, stiffness, and impact resistance, making it suitable for various demanding applications within vehicles.

Q2: How does reinforced polyamide improve the mechanical properties of automotive components?

- The inclusion of reinforcing agents in polyamide significantly enhances its tensile strength, stiffness, and impact resistance. This makes the material robust and capable of withstanding mechanical stresses and impacts, which are common in automotive operations.

Q3: What are the advantages of using reinforced polyamide in engine components?

- It offers high thermal stability and resistance to oils and coolants, making it ideal for engine parts such as oil pan covers, water pump housings, and fuel tank components. It also contributes to the rigidity and stability of engine mounts and suspension components, ensuring reliable performance under high stress.

Q4: In what ways is reinforced polyamide beneficial for automotive electrical and electronic applications?

- It excels in electrical and electronic applications due to its excellent electrical insulation and resistance to temperature variations. It is commonly used in wire harnesses, electrical connectors, and battery trays, as well as in fuel injection systems and emission control components, where it must withstand harsh environmental conditions.

Q5: Why is reinforced polyamide used in the interior components of vehicles?

- It is used for interior components because of its excellent impact resistance and high-quality surface finish. It is suitable for dashboard components, door panels, and interior trim pieces. Additionally, its durability under repeated handling and temperature changes makes it ideal for automotive seating systems.

Q6: How does reinforced polyamide contribute to the overall durability and performance of automotive components?

- It enhances the durability and reliability of automotive parts by offering superior mechanical properties and resistance to environmental factors. This results in longer-lasting components, reduced maintenance costs, and improved fuel efficiency due to its lightweight nature, which enhances vehicle performance.

Q7: What are the broader benefits of using reinforced polyamide in automotive manufacturing?

- The broader benefits of using it in automotive manufacturing include its versatility, cost-effectiveness, and ability to improve the performance, durability, and reliability of various vehicle components. Its widespread use in engine systems, electrical and electronic applications, and interior parts highlights its significance in modern automotive design and engineering.

Q8: How is the role of reinforced polyamide expected to evolve in the future automotive industry?

- As the automotive industry continues to seek improvements in vehicle performance and efficiency, the role of reinforced polyamide is expected to grow. Its unique properties and adaptability make it a critical material for developing more durable, reliable, and efficient automotive components in the future.