Nylon PA66 má rad vynikajúcich vlastností, ako je vysoká mechanická pevnosť, chemická odolnosť, odolnosť proti olejom, odolnosť proti opotrebovaniu, samomazanie a ľahké spracovanie a tvarovanie. Stal sa jedným zo široko používaných termoplastických technických plastov doma aj v zahraničí.

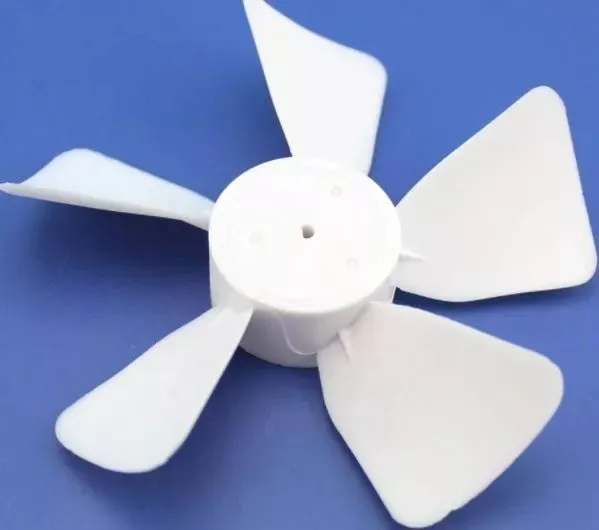

V praktických aplikáciách sa však požiadavky na výkon nylonu PA66 v rôznych podmienkach použitia alebo v rôznych prostrediach líšia.Napríklad komponenty, ako sú elektrické vŕtačky a kryty motorov, obežné kolesá čerpadiel, ložiská, dieselové motory a klimatizačné celoplastové ventilátory, vyžadujú, aby nylonové materiály mali vysokú pevnosť, vysokú tuhosť a vysokú rozmerovú stabilitu; vzhľadom na nízku húževnatosť nylonu pri nízkych teplotách je potrebné ho v tomto čase spevniť a upraviť; v niektorých vonkajších aplikáciách sa nylonové materiály musia upraviť na odolnosť voči poveternostným vplyvom v dlhodobom vonkajšom prostredí atď.

Výstužné materiály používané vo vystuženom nylone PA66 sú najmä vláknité látky, ako sú sklenené vlákna, uhlíkové vlákna a whiskery, a spomedzi nich sa najčastejšie používa výstuž zo sklenených vlákien.Výstuž zo sklenených vlákien môže výrazne zlepšiť pevnosť a tvrdosť materiálu a výrazne zlepšiť rozmerovú stabilitu a tepelnú odolnosť materiálu.

Keďže samotný nylon PA66 nie je dostatočne pevný, jeho pevnosť sa zvyšuje pridaním vlákien 10-30%.Najmä pevnosť 30% sa považuje za najvhodnejší pomer.Môže sa tiež zvýšiť na 40-50%. Podľa špecifických požiadaviek rôznych výrobkov v spojení s vhodným vzorcom môže byť úspešný.

Výrobný proces výrobkov vystužených sklenenými vláknami PA66 Nylon

Vo všeobecnosti existujú dva výrobné postupy pre nylon vystužený sklenenými vláknami: metóda dlhých vlákien a metóda krátkych vlákien.

Metóda dlhých vlákien, to znamená, že nylon a ostatné zložky sa pridávajú do násypky po tom, ako sa vopred zmiešajú, zatiaľ čo sklenené vlákno sa otáča od vstupu skleneného vlákna cez skrutku, aby sa dostalo do skrutky, a potom sa zmieša s nylonovou živicou.

Metóda strižných vlákien spočíva v tom, že sa nasekané sklenené vlákno vtlačí do suda cez bočné podávanie a potom sa zmieša s nylonom.

Faktory ovplyvňujúce vlastnosti nylonu PA66 vystuženého sklenenými vláknami

Nylon PA66 vystužený sklenenými vláknami starne pri spracovaní teplom a kyslíkom

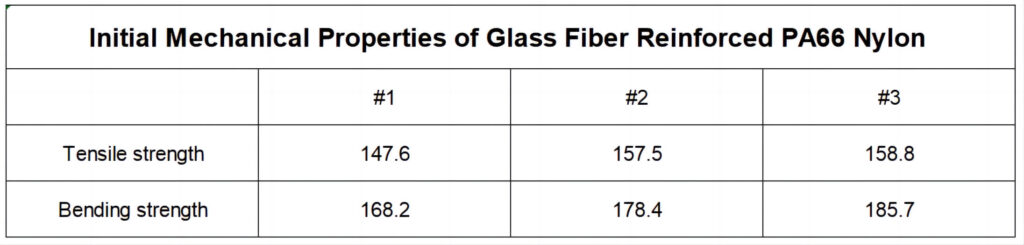

Z údajov v tabuľke je zrejmé, že pevnosť v ťahu, pevnosť v ohybe a rázová húževnatosť vzoriek 1# bez pridania antioxidantov sú nižšie ako zodpovedajúce vlastnosti vzoriek 2# a 3#, čo ukazuje, že pridanie antioxidantov môže účinne blokovať tepelné starnutie kyslíka a degradáciu nylonu 66 počas spracovania a výrazne zlepšiť mechanické vlastnosti kompozitných materiálov.To ukazuje, že vhodný antioxidačný systém môže zohrávať lepšiu úlohu pri stabilizácii počiatočného spracovania.

Sklo Fiber Enhances Fluidity PA66 Nylon

Tekutosť nylonu vystuženého sklenenými vláknami je nízka a je náchylná na problémy, ako je vysoký vstrekovací tlak, vysoká teplota vstrekovania, nespokojné vstrekovanie a zlá kvalita povrchu počas procesu vstrekovania, čo vážne ovplyvňuje vzhľad výrobku a vedie k vysokej miere chybovosti výrobku.Najmä vo výrobnom procese vstrekovaných výrobkov nemožno na vyriešenie tohto problému priamo pridať mazivá a možno ich len zlepšiť na surovinách. Vo všeobecnosti si to vyžaduje pridanie mazacích zložiek do upraveného vzorca.

Odolnosť voči High Temperatúra a Xxygen Aging of Glass Fiber Rvynútené PA66 Nylon

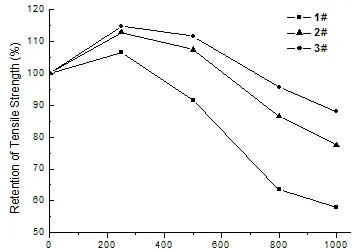

V niektorých oblastiach použitia, ako sú ložiská a ventilátory dieselových motorov, nylon vystužený sklenenými vláknami často čelí problému dlhodobého vysokoteplotného tepelného starnutia kyslíka.Hoci vylepšenie a modifikácia nylonu sklenenými vláknami môže mierne zlepšiť tepelnú odolnosť nylonu, nemôže tento problém dobre vyriešiť. Lepšie výsledky možno dosiahnuť pridaním vhodných prísad proti tepelnému a kyslíkovému starnutiu do kompozitného materiálu nylonu vystuženého sklenými vláknami. Postupujte podľa uvedeného obrázka.

Po 1000-hodinovom starnutí troch vzoriek tepelným kyslíkom bola miera zachovania pevnosti v ťahu vzorky 1# (bez antioxidantu) 58,0%, miera zachovania pevnosti v ťahu vzorky 2# (všeobecne bežne používaný antioxidačný systém) bola 77.Je vidieť, že vhodný antioxidačný systém môže účinne oddialiť tepelné kyslíkové starnutie a degradáciu nylonu vystuženého sklenenými vláknami, takže môže mať lepší účinok na ochranu pred vysokoteplotným tepelným kyslíkovým starnutím.

Odolnosť nylonu PA66 vystuženého sklenenými vláknami voči poveternostným vplyvom

Nylon PA66 je ovplyvňovaný vonkajšími podmienkami, ako sú slnečné žiarenie, zmeny teploty, vietor a dážď atď., a dochádza k sérii javov starnutia, ako je blednutie, zmena farby, praskanie, kriedovanie a zníženie pevnosti. Medzi nimi je kľúčovým faktorom podporujúcim starnutie ultrafialové žiarenie. nylon odolný voči poveternostným vplyvom je v súčasnosti hlavne čierny výrobok, to znamená, že jeho odolnosť voči poveternostným vplyvom sa rieši pridaním sadzí a iných prísad, ktoré absorbujú ultrafialové žiarenie do nylonu. okrem čiernych výrobkov však prírodný alebo svetlý nylon často čelí problémom so starnutím pri používaní vo vonkajšom prostredí, najmä v dôsledku žltnutia častí.

Použitie nylonu s rôznymi podielmi vlákien

1.Vysokopevnostné výrobky vystužené sklenenými vláknami.

Vystužený nylonový materiál s pomerom prídavku sklených vlákien 40-50% je vhodný najmä na výrobu vysokopevnostných prevodov a vysokopevnostných častí profesionálnych zariadení.

Rôzne presné prevody

2. Stredne pevné výrobky vystužené sklenenými vláknami.

Aplikácia4: Kuchynský riad:

Vysoká teplotná odolnosť, potravinárska trieda, vysoká tekutosť, zvýšená, PA66+30%GF.

Aplikácia 5: Pole hračiek

Držiaky hračkárskych pištolí, vrtule dronov a držiaky motorov vo všeobecnosti používajú stredne a vysokopevnostné modifikované plasty, PA66+30% GF a PA66+30% uhlíkové vlákna.

3. Výrobky vystužené sklenenými vláknami s nízkou pevnosťou

Vystužený nylonový materiál s pomerom prídavku sklených vlákien 10-20% je vhodný najmä na výrobu konektorov, dotykových spínačov, zdravotníckych zariadení a iných častí v elektronických a elektrických výrobkoch.