Chemical Composition: Recycled Polyamide vs. Polyester Different Chemical Foundations Recycled polyamide and polyester, though often confused, are fundamentally different in their chemical makeup. Polyamide, commonly known as nylon, is synthesized from adipic acid and hexamethylene diamine. In contrast, polyester is derived from polyethylene terephthalate (PET), produced from ethylene glycol and terephthalic acid. These distinct chemical […]

Author Archives: Katrina

Optimizing Material Orientation and Layup To maximize the benefits of PA66GF, engineers must meticulously choose the material’s orientation and layup pattern. The glass fibers within PA66GF can be aligned in specific directions to enhance various mechanical properties like tensile and flexural strength, and impact resistance. For instance, a unidirectional layup boosts tensile strength significantly, whereas […]

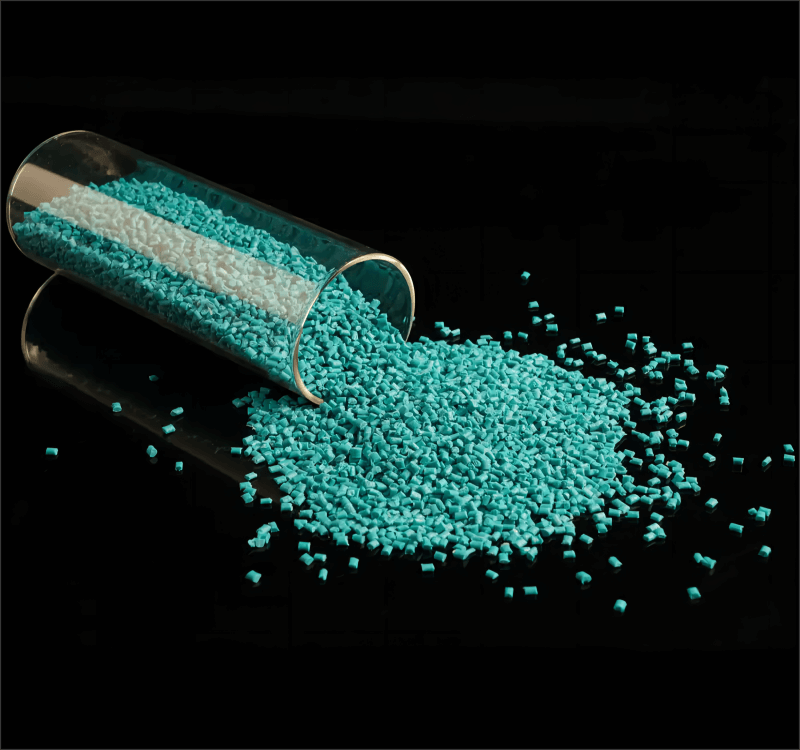

PA Polyamide, often referred to by its commercial name, nylon, is a synthetic polymer that has transformed various industries with its exceptional properties. Known for its strength, versatility, and resilience, polyamide is used in a myriad of applications, from everyday textiles to high-performance aerospace components. The Chemical Structure and Properties of PA Polyamide Polyamide is […]

Nylon, a versatile and durable synthetic polymer, has been a game-changer in the textile industry. Among the different types of nylon, nylon2 nylon6 stand out for their unique attributes. Despite their common usage across various fields, nylon2 and nylon6 differ significantly in their chemical makeup, production methods, and inherent properties. This guide explores these differences […]

Introduction to PA66 GF20 PA66 GF20, also referred to as Nylon 66, stands out as a semi-crystalline thermoplastic renowned for its outstanding mechanical characteristics. With attributes like high strength, stiffness, and toughness, it becomes particularly effective for applications demanding robust performance. Enhanced Mechanical Properties with Glass Fiber The incorporation of 20% glass fiber into PA66 […]

In today’s dynamic global economy, effective collaboration is pivotal to successful supply chain management. PA6 6 6f30 is revolutionizing this landscape by enhancing collaboration among suppliers, manufacturers, and logistics providers. The Importance of Collaboration in Supply Chain Operations In the realm of supply chain operations, collaboration is more than a buzzword—it’s a strategic imperative. Businesses […]

PA66: Strength and Versatility PA66, known for its strength and durability, is a thermoplastic polymer widely utilized in automotive, aerospace, and electronics. Its ability to withstand high temperatures makes it ideal for engine components and structural parts in automobiles, as well as for lightweight aircraft components. GF15: Enhancing Performance and Efficiency GF15, a high-performance lubricant, […]

Sourcing Monomers for Nylon Production The production of nylon starts with the synthesis of its key monomers. Adipic acid and hexamethylenediamine (HMDA) are the primary chemicals involved. Adipic acid is generated through the oxidation of cyclohexane, while HMDA is produced via a reaction between ammonia and formaldehyde. These two monomers are then combined in an […]

Nylon 6 6 is a widely utilized synthetic fiber that has become a staple in numerous industries, thanks to its remarkable characteristics. This article explores the intricate chemical structure of Nylon 6 6, its distinct features, and how it compares with other types of nylon. Chemical Structure of Nylon 6 6 Nylon 6 6 stands […]

Revolutionizing Aerospace with PA6 The aerospace sector heavily relies on polyamide 6 PA6 for various components, including aircraft interiors, fuel systems, and engine parts. PA6’s lightweight nature and high strength-to-weight ratio are vital in reducing the overall weight of aircraft, enhancing fuel efficiency, and lowering emissions. This combination of properties makes PA6 a key material […]