Automotive Industry Applications Enhancing Performance and Efficiency in Vehicles In the automotive sector, PA66 GF33 composites are integral in the manufacturing of components like engine parts, transmission systems, and body panels. Their high strength-to-weight ratio allows for the production of lightweight yet robust parts capable of withstanding significant loads and high temperatures. This not only […]

Delve into the manufacturing process of PA6 CF, from the extraction of raw materials to the final product, and discuss the challenges and opportunities associated with producing this material. Introduction to PA6 CF Polyamide 6 (PA6) reinforced with carbon fiber (CF) is celebrated for its high-performance qualities, including exceptional strength, stiffness, and resistance to fatigue. […]

The rapid evolution of the automotive industry demands materials that can enhance vehicle performance, durability, and safety. One material that has recently garnered significant interest is PA6 GF35. This advanced polymer brings a host of benefits to automotive applications. This article delves into the numerous advantages of PA6 GF35 and its contribution to vehicle efficiency […]

Superior Wear and Abrasion Resistance One of the hallmark features of PA6 GF15 is its remarkable resistance to wear and abrasion. This quality is essential for components that experience constant friction, such as conveyor belts, gears, and bearings. The material’s ability to endure prolonged usage without significant wear ensures lower maintenance costs and higher operational […]

Polyamide Vs Nylon Polyamide vs nylon, two stalwarts in the realm of synthetic polymers, stand as pillars of modern industrial innovation. While sharing the common thread of amide connections, these materials diverge in their chemical compositions and properties, offering unique advantages across a spectrum of applications. From their inception to their widespread adoption in consumer […]

Strength and Durability for Demanding Conditions Polyamide nylon boasts exceptional strength and durability, pivotal attributes for sporting and outdoor equipment. Its robust tensile strength enables it to endure substantial stress, making it an ideal choice for high-performance gear like climbing harnesses, ski bindings, and protective apparel. Moreover, its resistance to abrasion ensures longevity, vital […]

Introduction of Nylon 6 and 66 Nylon 6: Crystalline Durability and Color Diversity Nylon 6, also referred to as polyamide 6, boasts a crystalline structure derived from six carbon atoms and six hydrogen atoms. This inherent structure grants it remarkable mechanical attributes like tensile strength and impact resistance. Its outstanding abrasion resistance further enhances its […]

Unveiling Polyamide Material’s Strength Polyamide, commonly known as nylon, has emerged as a versatile and durable material prized across industries for its exceptional strength and resilience. Delving into its unique properties sheds light on its growing demand and widespread applications. Remarkable Strength-to-Weight Ratio A standout characteristic of polyamide lies in its remarkable strength-to-weight ratio. […]

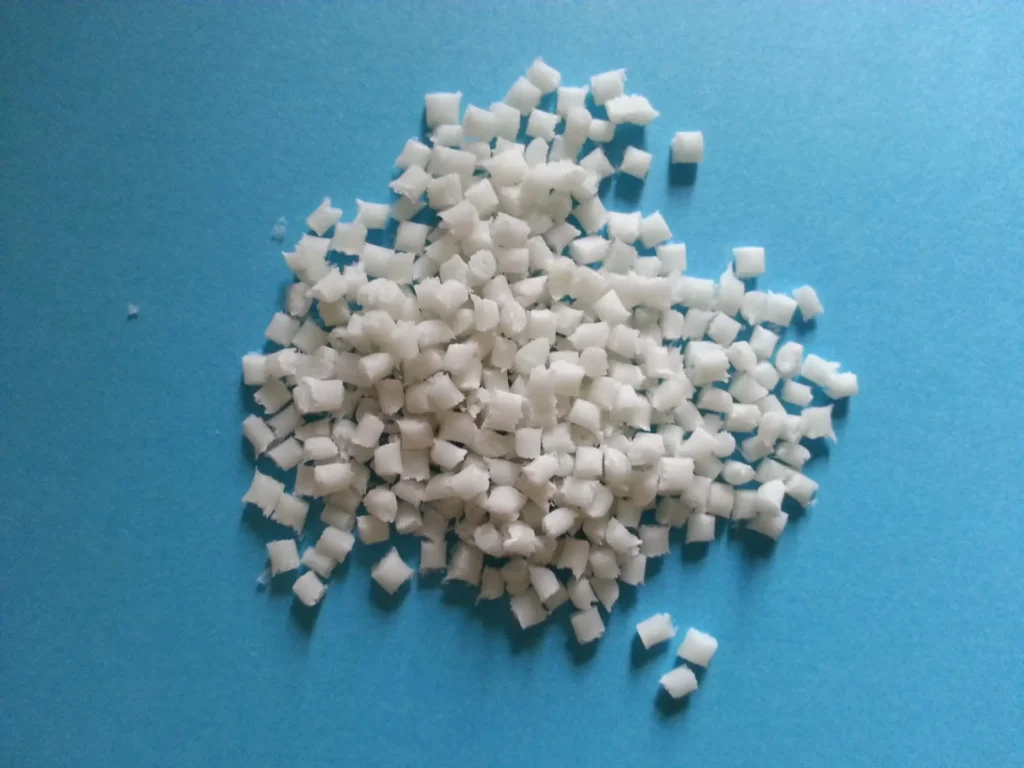

Introduction: Versatility and Application of Nylon 6 PA6 Nylon 6 PA6 is a semi-crystalline polymer known for its versatility and widespread use across industries such as automotive, electronics, and textiles. This article explores the detailed production process of it, highlighting each step from its chemical origins to its final form. Synthesis of Caprolactam: The […]

The Genesis of 66Nylon in Mid-20th Century China The origins of it trace back to China in the 1950s, a period marked by rapid industrialization. In 1958, one of the Zhejiang company began its quest to produce high-quality nylon yarn, setting the stage for what would become a groundbreaking development in synthetic fibers. Overcoming Early […]