Application of Nylon Introduction Nylon has become a critical material in the aerospace industry due to its unique properties and versatile applications. Its adoption has led to improved performance, cost efficiency, and technological advancements in aircraft and spacecraft manufacturing. This article explores the various ways nylon is transforming the aerospace sector. Strength-to-Weight Ratio: Key to […]

Category Archives: Nylon

Does Nylon Shrink? Nylon, a popular synthetic fabric, is widely valued for its durability, resistance to abrasion, and ease of care. However, a common concern among users is whether nylon shrinks when exposed to heat. This article explores the properties of nylon and the conditions under which it may or may not shrink. What […]

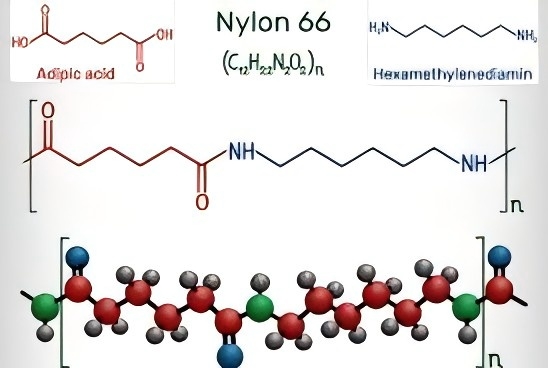

Density of Nylon 6/6 Introduction Nylon 6/6, also known as poly(hexamethylene adipamide), is a synthetic polymer celebrated for its exceptional mechanical properties, chemical resistance, and thermal stability. Its versatility makes it a popular choice in various industries, from textiles to engineering plastics. One of the key characteristics that affect the performance of Nylon 6/6 in […]

Introduction of Nylon vs PP In the world of synthetic polymers, nylon vs PP (polypropylene) stand out due to their widespread use and adaptability. These thermoplastic polymers share some similarities but also possess distinct characteristics that make them suitable for different applications. This article provides a detailed comparison between nylon vs PP, examining their properties, […]

What is Nylon Composition? Definition and StructureNylon is a type of polyamide, a class of polymers known for the presence of amide functional groups (-CONH-) in their molecular structure. These groups are formed by the reaction between a carboxylic acid and an amine, creating a peptide bond. In nylon, these components are derived from petrochemicals, […]

The Unique Properties of PA6 Plastic Material A Strong and Flexible Polymer PA6 is composed of monomers linked together to create a robust and durable polymer. Its high tensile strength, flexibility, and abrasion resistance make it an excellent choice for numerous applications. Additionally, its outstanding chemical resistance allows it to perform well in harsh […]

Nylon is a highly versatile synthetic polymer that finds extensive use in a variety of applications, ranging from textiles to industrial components and consumer products. The operating temperature range is a critical factor influencing nylon’s performance and durability. Understanding the ideal temperature range for nylon in different contexts is essential to ensure its optimal functioning […]

Stiffness-to-Weight Ratio of PA12GF30 One of the primary attributes of PA12GF30 that makes it appealing in aerospace engineering is its high stiffness-to-weight ratio. This characteristic renders it ideal for applications where reducing weight is paramount, such as in aircraft components and satellite parts. The material’s impressive stiffness allows for lightweight designs that do not compromise […]

Significance of PA6 Melting Point The Melting Point Defined The melting point of PA6 ranges from 220-230°C, which is relatively high when compared to other thermoplastics. This elevated melting point is attributed to the strong intermolecular forces, primarily hydrogen bonds, between the polymer chains. Understanding this melting point is essential as it dictates PA6’s processability, […]

Molecular Structure and Mechanical Properties of Nylon PA12 It is a semi-crystalline polymer with outstanding mechanical properties, such as high tensile strength, stiffness, and impact resistance. Its strength is derived from its unique molecular structure, composed of repeating amide groups (-CONH-) linked by carbon atoms. This configuration results in a high degree of crystallinity, creating […]