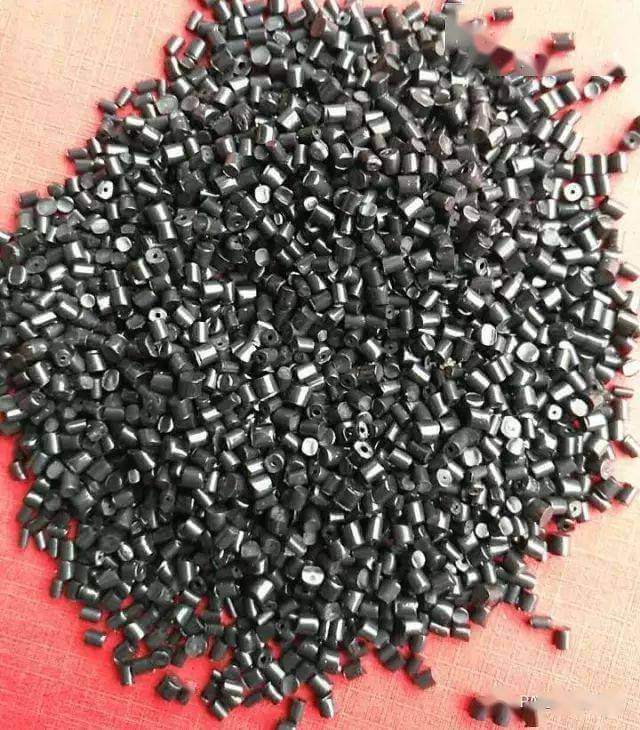

Sissejuhatus Nailon PA 66

Adipiinhappest ja heksametüleendiamiinist sünteesitud nailon PA 66 paistab silma kui väga mitmekülgne tehniline termoplast. See poolkristalliline lineaarne polümeer on ainulaadsete omadustega, mis muudavad selle oluliseks erinevates tööstussektorites.

Keemiline struktuur ja süntees

Nailon PA 66 toodetakse adipiinhapet ja heksametüleendiamiini hõlmava kondensatsioonipolümerisatsiooni teel. Tugeva happe või aluse poolt katalüüsitud reaktsioon annab polümeeri, mille korduvad ühikud on -(NH-CO-R-CO-NH-), kus "R" tähistab adipiinhappe alifaatset ahelat. See struktuur on polümeeri märkimisväärsete omaduste aluseks.

Füüsikalised omadused ja eelised

Nailon PA 66 poolkristalliline olemus annab märkimisväärseid eeliseid, sealhulgas suure tõmbetugevuse, suurepärase kulumiskindluse ja märkimisväärse löögikindluse. Kõrge sulamistemperatuur suurendab veelgi selle kasutatavust kõrge temperatuuriga rakendustes.

Keemiline vastupidavus ja elektriline isolatsioon

PA 66 on väga keemiliselt vastupidav, talub erinevaid happeid, aluseid ja orgaanilisi lahusteid. Selle vastupidavus laieneb ka elektrilistele rakendustele, pakkudes suurepäraseid isolatsiooniomadusi, mis on olulised ohutuse ja usaldusväärsuse tagamiseks nõudlikes keskkondades.

Autotööstuse rakendused

Autotööstuses on Nailon 66 lahutamatu osa mootori ja jõuülekande komponentide, näiteks hammasrataste, rihmarataste ja laagrite valmistamisel. Selle suurt tugevuse ja kaalu suhet ja kulumiskindlust täiendab selle võime säilitada jõudlust sõidukite intensiivse kuumuse tingimustes.

Rakendused elektroonika- ja elektritööstuses

Elektri- ja elektroonikasektor kasutab Nailon PA 66 komponente, näiteks pistikuid, lüliteid ja isolaatoreid. Selle suurepärane elektriisolatsioon ja jälgimiskindlus teevad sellest usaldusväärse materjali nende kriitiliste rakenduste jaoks.

Kasutamine tekstiilides

Nailon 66 on tuntud ka tekstiilitööstuses, eriti kiudude tootmisel. Selle kõrge tõmbetugevus, elastsus ja kulumiskindlus muudavad selle ideaalseks vastupidavaks ja kauakestvaks tekstiiliks.

Kokkuvõte

Nailon PA 66 on oma eriliste omaduste tõttu jätkuvalt nurgakiviks erinevates tööstusharudes. Selle kõrge tõmbetugevus, suurepärane kulumis- ja löögikindlus, kõrge sulamistemperatuur ja suurepärane keemiline vastupidavus kinnitavad selle rolli asendamatu tehnilise termoplastina. Nailon PA 66 on endiselt usaldusväärne ja kõrgtehnoloogiline valik paljude rakenduste jaoks, alates autotööstusest kuni tekstiilideni.

Korduma kippuvad küsimused

1.Mis on Nylon PA 66?

Vastus:

PA 66 on tehniline termoplast, mis on tuntud oma tugevuse ja vastupidavuse poolest. See on polümeer, mis on valmistatud adipiinhappe ja heksametüleendiamiini kondensatsioonireaktsioonist. Tulemuseks on suurepärase mehaaniliste ja termiliste omadustega materjal, mis muudab selle sobivaks paljude erinevate rakenduste jaoks.

2.Millised on Nylon PA 66 peamised rakendused?

Vastus:

Nailon 66 kasutatakse laialdaselt erinevates tööstusharudes tänu selle mitmekülgsusele ja tugevale toimimisele. Peamised rakendused on järgmised:

- Autotööstus:Mootori ja jõuülekande komponendid, nagu hammasrattad, rihmarattad ja laagrid.

- Elektri- ja elektroonikaseadmed:Ühendused, lülitid ja isolaatorid.

- Tekstiilid:Vastupidavad kiudained kangaste ja vaipade jaoks.

- Tööstuslik:Osad ja komponendid, mis nõuavad suurt mehaanilist tugevust ja kulumiskindlust.

3. Kuidas sünteesitakse nailon PA 66?

Vastus:

See sünteesitakse protsessi kaudu, mida nimetatakse kondensatsioonipolümerisatsiooniks. See hõlmab adipiinhappe reageerimist heksametüleendiamiiniga katalüsaatori juuresolekul. Reaktsiooni käigus tekivad pikaahelalised molekulid korduvate ühikutega, mis moodustavad PA 66-le iseloomuliku poolkristallilise polümeeristruktuuri.

4. Millised on nailon PA 66 põhiomadused?

Vastus:

Nailon 66-l on mitu olulist omadust:

- Kõrge tõmbetugevus:See peab vastu märkimisväärsele koormusele ilma purunemiseta.

- Suurepärane kulumiskindlus:See on kulumiskindel ja vastupidav, mis muudab selle vastupidavaks.

- Hea löögikindlus:See neelab ja talub tõhusalt põrutusi.

- Kõrge sulamistemperatuur:Sobib kõrge temperatuuriga rakendusteks.

- Keemiline vastupidavus:See on vastupidav paljude hapete, aluste ja lahustite suhtes.

- Elektriisolatsioon:See tagab usaldusväärsed isolatsiooniomadused, mis on elektriliste rakenduste jaoks väga olulised.

5. Kuidas mõjutab nailon PA 66 keemiline struktuur selle omadusi?

Vastus:

PA 66 keemiline struktuur, mida iseloomustavad korduvad üksused -(NH-CO-R-CO-NH)-, kus "R" on alifaatne ahel, aitab kaasa selle poolkristallilisele olemusele. Selline struktuur tagab jäikuse ja paindlikkuse tasakaalu, mis võimaldab materjalil olla kõrge mehaaniline tugevus, kulumiskindlus ja termiline stabiilsus.

6. Kas Nailon PA 66 on kemikaalide suhtes vastupidav?

Vastus:

Jah, Nailon 66 on suurepärase vastupidavusega paljude kemikaalide, sealhulgas erinevate hapete, aluste ja orgaaniliste lahustite suhtes. See muudab selle sobivaks kasutamiseks keskkondades, kus see võib kokku puutuda söövitavate ainetega.

7. Millised on Nailon PA 66 kasutamise eelised mootorsõidukites?

Vastus:

Autotööstuses eelistatakse Nailon 66't selle suure tugevuse ja kaalu suhte tõttu, mis aitab kaasa sõiduki tõhususele ja jõudlusele. Tema suurepärane kulumiskindlus tagab komponentide pikaealisuse, samas kui tema termiline stabiilsus võimaldab tal usaldusväärselt toimida kõrgetel temperatuuridel, mida tavaliselt mootori- ja jõuülekandesüsteemides kasutatakse.

8. Miks eelistatakse elektri- ja elektroonikakomponentides Nylon PA 66?

Vastus:

Nailon 66 valitakse elektri- ja elektroonikarakenduste jaoks, sest sellel on suurepärased elektriisolatsiooniomadused, mis on olulised elektririkete vältimiseks ja ohutuse tagamiseks. Lisaks sellele muudavad tema vastupidavus jälgimisele ja termiline stabiilsus selle ideaalseks komponentide, näiteks pistmike ja isolaatorite jaoks.

9. Kas nailon PA 66 võib kasutada tekstiilides?

Vastus:

Jah, nailon 66 kasutatakse laialdaselt tekstiilitööstuses, eriti kiudude tootmisel. Selle kõrge tõmbetugevus, elastsus ja kulumiskindlus muudavad selle sobivaks rakendusteks, mis nõuavad vastupidavaid ja vastupidavaid materjale, näiteks rõivad, vaibad ja tööstuslikud kangad.

10. Kuidas on Nylon PA 66 võrreldav teiste nailonitüüpidega?

Vastus:

Nailon 66 võrreldakse sageli teiste nailonitega, nagu näiteks Nailon 6selle paremate mehaaniliste omaduste ja kõrgema sulamistemperatuuri tõttu. See kipub paremini toimima rakendustes, mis nõuavad suurt tugevust ja soojuskindlust. Nailon PA 66 võib siiski olla kallim ja veidi vähem paindlik kui mõned teised nailonid, näiteks Nailon 6, mis võib olla eeliseks teatud kasutusaladel.

11. Kas Nylon PA 66 on keskkonnasõbralik?

Vastus:

Nailon 66 keskkonnamõju sõltub mitmest tegurist, sealhulgas selle tootmisest, kasutamisest ja kõrvaldamisest. Kuigi see on vastupidav ja kauakestev, vähendades vajadust sagedase väljavahetamise järele, võivad selle süntees naftapõhisest toorainest ja ringlussevõtuga seotud probleemid tekitada keskkonnaprobleeme. Nende probleemide lahendamiseks tehakse jõupingutusi ringlussevõtu parandamiseks ja biopõhiste alternatiivide väljatöötamiseks.

12. Kuidas tuleb hooldada Nailon PA 66 komponente?

Vastus:

Nailon 66 komponentide hooldamine hõlmab regulaarset kontrolli ja puhastamist, et vältida saasteainete kogunemist, mis võivad mõjutada töövõimet. Auto- ja tööstusrakenduste puhul võib Nailon 66 osade kasutusiga pikendada nõuetekohase määrimise tagamine ja kokkusobimatute kemikaalidega kokkupuute vältimine. Tekstiilide puhul aitab materjali omadusi säilitada materjalile omaste hooldusjuhiste järgimine.

13. Kust leida lisateavet või osta Nylon PA 66?

Vastus:

Lisateavet Nailon 66 kohta leiab järgmiselt veebisaidilt materjalitarnijad, tehnilised andmelehed ja tööstusharu väljaanded. Ostmiseks on see saadaval erinevatelt tootjatelt ja turustajatelt, kes on spetsialiseerunud tehnilistele plastidele ja tööstuslikele rakendustele mõeldud materjalidele.