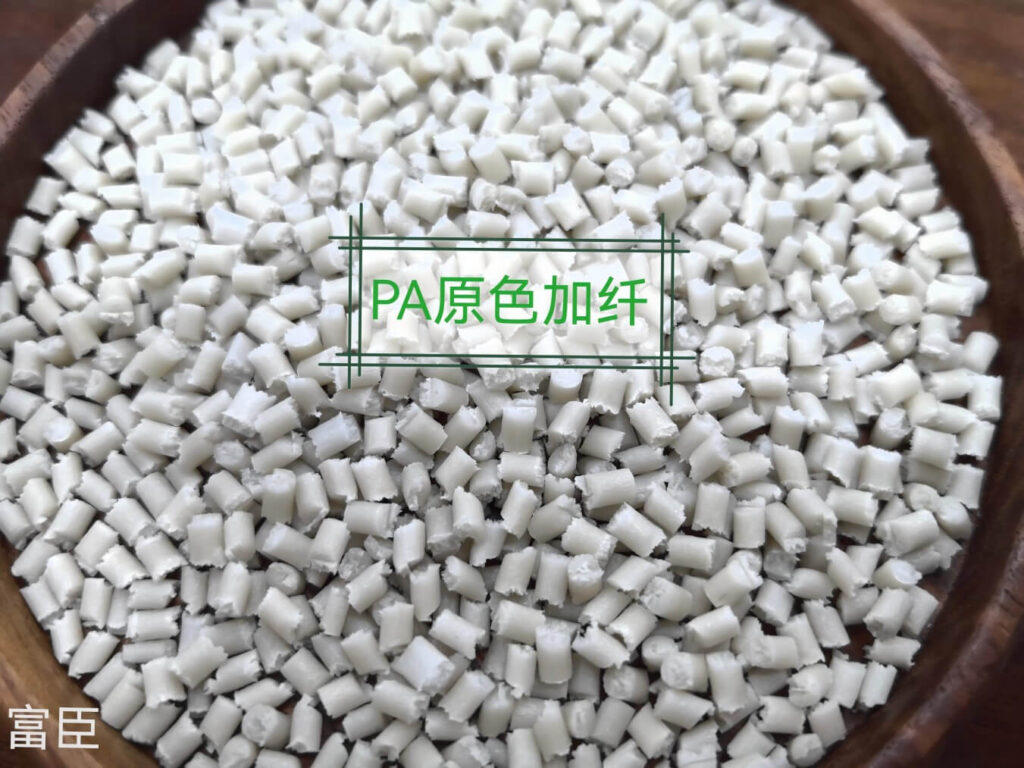

Introduction of Nylon 6 Granules

Nylon 6 granules have become an integral part of modern industries, renowned for their durability, versatility, and cost-effectiveness. This article explores the fascinating history of Nylon 6, from its inception to its current role across various sectors, while also considering its environmental impact and future potential.

Origins of Nylon 6 Granules: A Revolutionary Breakthrough

Nylon 6’s roots can be traced back to the 1930s, a time of great technological innovation. The development began with Wallace H. Carothers at DuPont, who sought to create a synthetic fiber to compete with silk in strength and durability. After years of dedicated research, the first Nylon was synthesized in 1935, marking a turning point in polymer science.

Refining the Formula: The Birth of Nylon 6

Nylon 6, also known as polycaprolactam, emerged from enhancements to the original Nylon formula. Its unique chemical structure, consisting of repeating caproamide units, gives Nylon 6 its remarkable properties. These include strength, flexibility, and resistance to wear, which have made it suitable for a wide range of applications.

The Commercialization of Nylon 6 Granules

The commercial production of Nylon 6 began in the 1940s. Though DuPont initially introduced Nylon 6,6 in 1940, it was Julian Hill’s efforts that led to the mass production of Nylon 6 by 1945. This new version offered industries a more efficient and cost-effective material, revolutionizing various sectors.

Properties That Power Versatility

Nylon 6 granules owes its widespread use to its exceptional properties. It is known for high tensile strength, resistance to abrasion, and the ability to withstand chemicals and moisture. These characteristics make it indispensable in industries that demand durable and long-lasting materials.

Key Applications of Nylon 6 Granules in Industry

Nylon 6 is a key player in textiles, automotive, electronics, and packaging industries. In textiles, it’s used to manufacture items like clothing, carpets, and parachutes due to its strength. In the automotive sector, Nylon 6 is preferred for engine components and electrical parts, thanks to its heat resistance and durability.

Nylon 6’s Role in Electronics and Packaging

Nylon 6’s insulating properties make it ideal for the electronics industry, where it’s used in circuit boards and connectors. In packaging, Nylon 6 is employed to create containers that can withstand chemicals and moisture, making it essential for both food and industrial packaging.

Addressing Environmental Concerns

As a petroleum-based product, Nylon 6 granules raises environmental concerns. However, efforts are underway to mitigate its impact. Recycling programs are being developed to repurpose Nylon 6 waste, and research is being conducted into creating biodegradable alternatives to reduce the material’s ecological footprint.

Conclusion of Nylon 6 Granules

Nylon 6 granules have evolved from a groundbreaking discovery in the 1930s to a critical component in numerous industries today. Its unique properties ensure its continued relevance, while ongoing research promises exciting new applications in areas like biomedical engineering and 3D printing. As we move forward, balancing Nylon 6’s utility with sustainable practices will be essential to its future success.

Nylon 6 Granules: Summary FAQ

1. What is Nylon 6?

Nylon 6, also known as polycaprolactam, is a synthetic polymer with unique properties such as high tensile strength, abrasion resistance, and resistance to chemicals and moisture. It’s widely used in various industries due to its durability and versatility.

2.Who invented Nylon 6?

The original Nylon was developed in the 1930s by Wallace H. Carothers at DuPont. Nylon 6, a refined version, became widely produced after contributions by chemist Julian Hill in the 1940s.

3.How does Nylon 6 differ from other forms of Nylon?

Nylon 6 is distinct because of its chemical structure, which is composed of repeating caproamide units. This structure gives it exceptional strength, flexibility, and resilience, making it suitable for various applications.

4.What are the main industries using Nylon 6 granules?

Nylon 6 is extensively used in the textiles, automotive, electronics, and packaging industries. It’s found in products like clothing, carpets, engine parts, circuit boards, and packaging materials.

5.Why is Nylon 6 important in the textile and automotive industries?

In textiles, Nylon 6 is prized for its strength and durability, making it ideal for products like parachutes, clothing, and carpets. In the automotive industry, it’s valued for its resistance to heat and wear, making it useful in engine and electrical components.

6.How is Nylon 6 used in electronics and packaging?

Nylon 6’s insulating properties make it ideal for electronics, particularly in the production of circuit boards and connectors. In packaging, it’s used for containers that require chemical and moisture resistance.

7.What environmental concerns are associated with Nylon 6?

As a petroleum-based product, Nylon 6 has an environmental footprint. However, recycling programs and research into biodegradable alternatives are being developed to reduce its impact.

8.What does the future hold for Nylon 6?

Research into Nylon 6 is ongoing, with potential future applications in fields like biomedical engineering and 3D printing. Efforts to reduce its environmental impact will also play a significant role in its future development.