Introduction of Flame Retardant Nylon

Nylon, a widely used synthetic polymer, is popular for its strength, flexibility, and durability. However, in environments where fire resistance is crucial, such as in automotive, electronics, and industrial applications, standard nylon might fall short. This is where flame retardant nylon comes into play. Designed to resist ignition and slow the spread of flames, flame retardant nylon adds an essential layer of safety to products and applications that require it.

Importance of Flame Retardancy in Materials

The need for flame retardant materials has increased significantly in recent years due to safety regulations and the growing demand for safer products. Flame retardant materials help prevent fires from starting and spreading, reducing risks in various industries. In this context, flame retardant nylon has become an important option due to its balance of safety and performance.

Understanding the Properties of Flame Retardant Nylon

Chemical Composition and Structure of Flame Retardant Nylon

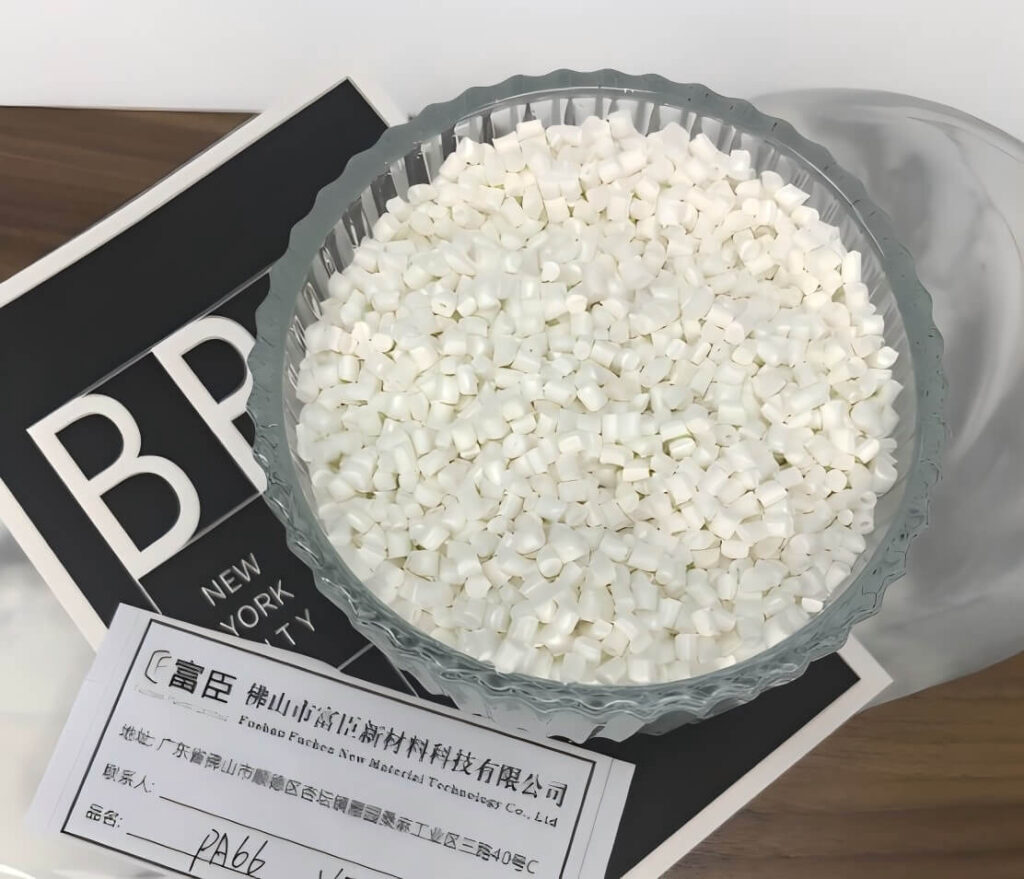

Flame retardant nylon is produced by modifying the chemical structure of nylon with flame-resistant additives or by blending it with other flame retardant compounds. These modifications help nylon resist burning and release fewer toxic gases in case of combustion. The structure often includes additives like phosphorus, halogens, or nitrogen, which play a critical role in interrupting the combustion process.

Mechanisms of Flame Retardancy in Nylon

Flame retardant nylon works primarily by two mechanisms: gas-phase inhibition and char formation. Gas-phase inhibition reduces the release of combustible gases that fuel fire, while char formation creates a protective barrier on the material’s surface, slowing down the spread of flames. Together, these mechanisms make flame retardant nylon highly effective at reducing fire hazards.

Applications of Flame Retardant Nylon

Textile Industry

In the textile industry, flame retardant nylon is used in protective clothing for firefighters, industrial workers, and military personnel. The material’s fire-resistant properties make it suitable for situations where exposure to flames or extreme heat is a concern. Additionally, it’s used in home textiles, such as carpets and draperies, where flame resistance is a desired safety feature.

Automotive Industry

Flame retardant nylon is also a key component in the automotive industry. It’s used for various interior parts like upholstery, seat belts, and headliners to enhance passenger safety. By using flame retardant materials in these components, manufacturers help meet safety standards and reduce the risk of fire spreading in case of an accident.

Electronics Industry

In electronics, flame retardant nylon plays a crucial role in insulating and protecting various components. Due to the risk of overheating in devices, flame retardant materials are used in cables, connectors, and circuit boards. These materials ensure that even if a short circuit occurs, the flames are less likely to spread, which is critical in preventing large-scale damage or device failure.

Advantages and Disadvantages of Flame Retardant Nylon

Advantages

One of the primary advantages of flame-retardant nylon is its enhanced safety. It offers protection in high-risk environments by reducing flammability and inhibiting the spread of fire. Furthermore, flame retardant nylon maintains the strength, flexibility, and durability associated with regular nylon, making it suitable for a wide range of applications. It also meets the necessary fire safety standards, helping industries comply with regulations.

Disadvantages

Despite its benefits, flame-retardant nylon also has some drawbacks. The use of flame retardant additives can impact the material’s environmental footprint, as some additives are not biodegradable and may release harmful chemicals during combustion. Additionally, flame retardant nylon is typically more expensive to produce than standard nylon, which can be a concern for budget-sensitive applications.

Future Developments in Flame Retardant Nylon

Emerging Technologies

Researchers are continually working to improve the flame retardant properties of nylon while minimizing environmental impact. New developments include bio-based flame retardant additives, which aim to reduce toxicity and enhance sustainability. Additionally, advancements in nanotechnology are being explored, where nano-scale materials can improve flame resistance while reducing the need for chemical additives.

Environmental Impact Considerations

As industries shift towards eco-friendly materials, there is a growing emphasis on reducing the environmental impact of flame-retardant nylon. Researchers are focusing on developing flame retardant additives that are both effective and environmentally benign, reducing potential health and ecological risks. This shift towards green flame retardants is expected to enhance the appeal of flame-retardant nylon in sustainable applications.

Commonly Asked Questions About Flame Retardant Nylon

1.Is Flame Retardant Nylon Safe for Use in Clothing?

Yes, it is generally safe for use in clothing, especially in protective gear where fire resistance is necessary. However, it’s essential to ensure that the flame retardant additives used are non-toxic and suitable for prolonged contact with skin, as some additives may cause irritation or have other health effects.

2.How Does Flame Retardant Nylon Compare to Other Flame Retardant Materials?

It is known for its strength and versatility, making it a preferred choice in applications requiring durable and fire-resistant materials. Compared to other flame retardant materials like polyester and polypropylene, flame-retardant nylon generally offers better mechanical properties, though it may be more expensive. Its unique balance of flame resistance and durability makes it a valuable choice in high-performance applications.

3.Can Flame Retardant Properties Be Added to Regular Nylon?

Yes, flame retardant properties can be added to standard nylon through post-treatment processes or by blending it with flame-resistant additives. However, achieving an effective level of flame resistance typically requires specialized additives and processing, which may increase the cost and impact the material’s properties. Pre-treated flame retardant nylon is usually more reliable for critical applications.

Conclusion

Flame retardant nylon is an essential material in industries that prioritize fire safety. From protective clothing and automotive interiors to electronic components, it offers a unique blend of durability, versatility, and flame resistance. While there are environmental and cost considerations, ongoing advancements in material science are paving the way for more eco-friendly flame retardant solutions. As flame retardant technologies continue to evolve, the use of safer, sustainable flame-retardant nylon is expected to grow across industries, making it an increasingly valuable choice in fire-safe applications.