In the precise context of modern industrial civilization, a seemingly ordinary but responsible material – food-grade nylon, is quietly reshaping the boundary of our contact with food with its excellent reliability and adaptability. It transcends the limitations of ordinary nylon, takes strict safety certification as the cornerstone, and weaves an invisible network to protect human health on a broad stage from kitchen fireworks to the core of industry.

The foundation of safety: material evolution beyond common sense

Food-grade nylon is by no means a simple extension of ordinary nylon. It has obtained the qualification of direct contact with food through high-purity screening of raw materials, precise proportioning of non-toxic additives and special process quenching. International authoritative certifications such as the US FDA standard or China’s strict GB4806.7-2016 “National Food Safety Standard Plastic Materials and Products for Food Contact” provide iron law guarantees for its safety. These standards set almost strict limits on harmful migrants (such as heavy metals and specific monomers) to ensure that it is non-toxic and tasteless throughout its “service”.

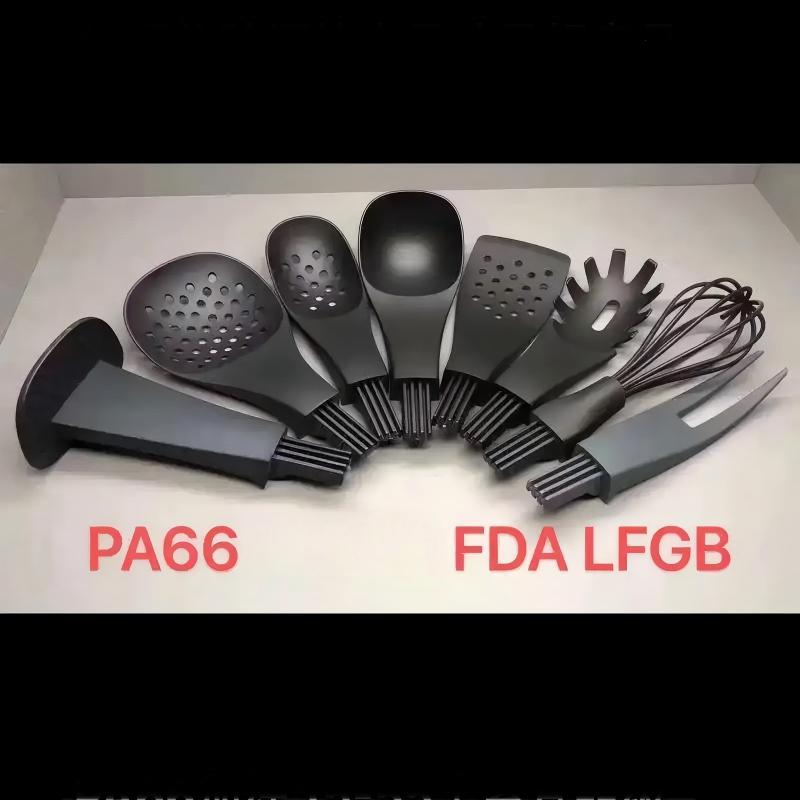

High temperature battlefield: the invisible guardian of kitchen utensils

In front of the stove with hot oil splashing, food-grade nylon shows amazing stability. Its temperature resistance range is usually between -40℃ and 220℃, which allows spatulas and high-temperature resistant clips to be at ease in boiling soup. The sealing ring of the inner lid of the Japanese Zojirushi rice cooker is made of this material. It has withstood the test of continuous steam for five years without aging and deformation, silently guarding the fragrance of rice. When purchasing, you must look for the QS mark or food contact material mark to avoid the hidden danger of high-temperature precipitation of inferior products.

Freshness-keeping revolution: the barrier master in the packaging field

Food-grade nylon has set off a silent revolution in the packaging field. Its excellent oxygen and moisture barrier properties greatly extend the shelf life of food. When a canned food company replaced traditional rubber with nylon sealing rings, the shelf life of the product was miraculously extended by eight months; and multi-layer composite nylon films (such as those used in coffee capsules and instant soup bags) can more effectively resist oil penetration and acid erosion. It is important to be vigilant that inferior packaging mixed with recycled materials may release toxins such as bisphenol A when heated – safe packaging, must-see certification.

Life Care: Precision Partner of Healthcare

In the healthcare field, the application of food-grade nylon is delicate and critical. The straws and anti-flatulence valves of baby bottles rely on their stability after repeated high-temperature disinfection; a study by Peking Union Medical College Hospital confirmed that their disinfection resistance is better than silicone and more suitable for the stringent requirements of the medical environment. Even more amazing is that the core material of invisible braces is specially modified food-grade nylon, which maintains precise morphological memory for more than 36 months in a complex oral environment.

Industrial Pillar: Durable Core of Food Machinery

Food-grade nylon plays an indispensable role in large-scale food machinery. Commercial dough mixer paddles, baking conveyor belt bearings, and filling machine seals all need to withstand the dual test of wear and corrosion. A technical report of an international food machinery giant pointed out that after its gears were switched to food-grade nylon, the continuous operation time jumped from 400 hours to 1,200 hours, and the industry chronic disease of lubricant contamination of dough was completely eliminated.

Customized future: creative shaping of 3D printing

3D printing technology has opened up a creative frontier for food-grade nylon. From the customized chocolate molds with clear textures of Michelin restaurants to the exquisite tools of molecular cuisine, professional-grade food-printed nylon (passed ISO10993 biocompatibility test) allows wild imaginations to land safely. Remember: ordinary 3D printing nylon materials do not meet food contact standards, and professional certification is the bottom line of safety.

Regulatory challenges: loopholes and warnings in the security network

The prosperous market hides hidden worries. Although China’s GB4806.7-2016 standard is clear and strict, market sampling shows that nearly 23% of the so-called “food-grade” products have excessive migration substances. In a provincial quality inspection, the nylon material of low-priced imitation porcelain bowls was found to contain 20 times more caprolactam monomer than the standard! Consumers can use a simple method to self-check: only those that have no pungent smell after boiling in boiling water and no white marks on the edges after repeated bending are reliable.

Frontier Exploration: Nanotechnology and the Road to Environmental Protection

Material research and development is moving towards a higher peak. The nano-grade food nylon developed by a university laboratory has improved its antibacterial performance by 75%, which is a leap forward. However, its cost, which is eight times that of traditional products, is like a mountain that stands in the way of commercialization. Environmental protection is also an urgent issue: Although it is safe in itself, it takes more than 80 years for food-grade nylon waste to degrade naturally, and a more powerful recycling system is urgently needed.

Extreme Mission: A reliable barrier from deep space to frozen soil

In the most harsh environments, food-grade nylon shows extraordinary value. NASA’s space meal packaging uses a seven-layer composite structure containing double-layer modified nylon to ensure that the food remains stable for three years in extreme temperature differences between -100℃ and 150℃; the Antarctic research station uses food-grade nylon pipes to solve the problem of low-temperature brittle cracking of metal water pipes, ensuring the trickle of polar lifeline.

Summary

Food-grade nylon, a material that combines cutting-edge technology and safety commitment, has stepped out from behind the scenes and become a silent guardian in the modern food chain. Its story is the eternal pursuit of safety by science – from the handle of the spatula to the meal bag in space, from the baby’s milk bottle to the water pipe in Antarctica, it builds a tangible safety wall with its invisible body.

When we enjoy convenience and deliciousness in the wave of technology, please remember to choose products with authoritative certification marks, avoid violent cleaning with steel wool, and replace utensils that have been used for more than 18 months or have scratches in time. Only by understanding and respecting the scientific boundaries of materials can this high-tech shield protect the safety and temperature of fireworks on earth for a long time.

Authoritative reference:

1. FDA – Food Contact Substances

2. GB 4806.7-2016 National Food Safety Standard