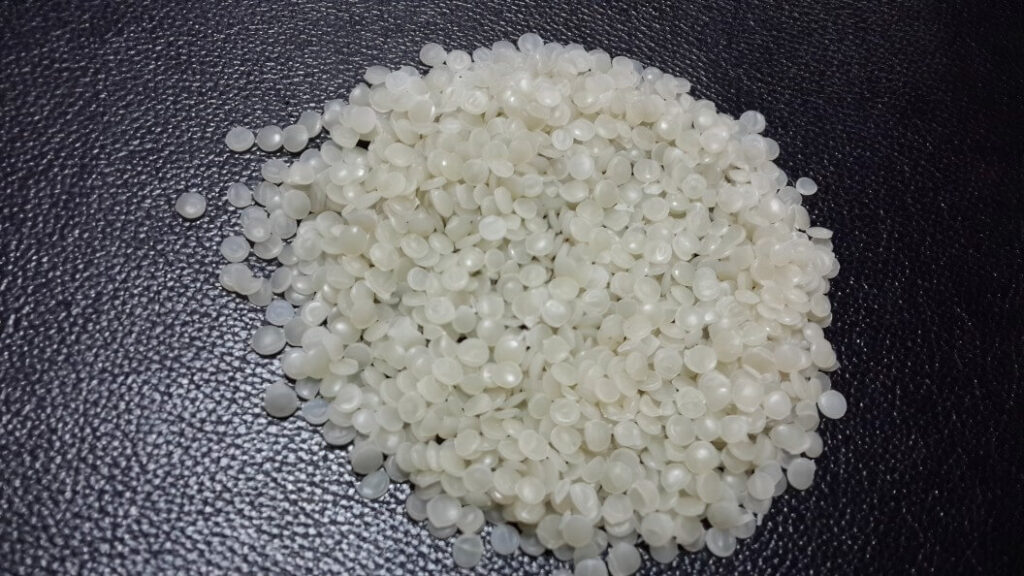

Introduction of PA6

With the global engineering plastics market exceeding US$70 billion, PA6 (nylon 6) is one of the five major general-purpose engineering plastics, and its procurement quality directly determines the performance of the end product. This article combines the certification standards of the International Purchasing Association with the latest industry data to systematically analyze the 10 key steps in PA6 raw material procurement, helping companies build a scientific procurement system and achieve dual optimization of quality and cost.

In-depth market research and demand confirmation of PA6

1. Technical parameter positioning: According to the ISO 1874-1 standard, key indicators such as melt index (MFI), viscosity value, and glass transition temperature are clarified. For example, automotive parts require MFI 35-45g/10min, while electronic connectors require MFI 20-30g/10min.

2. Application scenario analysis: Industrial-grade PA6 needs to focus on impact modification, food-grade materials must comply with FDA 21 CFR 177.1500, and medical-grade materials must meet ISO 10993 biocompatibility certification.

PA6 three-dimensional evaluation system for supplier screening

1. Qualification certification verification: Focus on reviewing ISO 9001 quality management system and IATF 16949 automotive industry certification.

2. Capacity matching verification: Refer to the data of China Plastics Processing Industry Association, and select large-scale production enterprises with a monthly output of more than 500 tons to ensure supply stability.

3. Technical response capability: Query the supplier’s technical reserves through the UL certified product database to evaluate its modified formula development capabilities.

Intelligent sourcing channel combination

1. Accurate docking of B2B platforms: Using the intelligent recommendation system of Alibaba International Station, Thomasnet and other platforms, combined with SEMrush data analysis, screen the TOP10 suppliers.

2. In-depth participation in industry exhibitions: Focus on participating in professional exhibitions such as the German K Show and the China Rubber and Plastics Exhibition to obtain the latest modification technology information.

3. Supply chain financial support: Connect with corporate credit platforms such as Euler Hermes to evaluate the financial health of suppliers.

PA6 technical communication and sample verification

1. Parameter confirmation double cycle: Establish a technical agreement confirmation table, including 23 key indicators.

2. Laboratory testing matrix: Entrust third-party institutions such as SGS and Intertek to conduct 6 major testing projects such as FTIR spectral analysis and DSC thermal analysis.

Business negotiation strategy optimization

1. Price model construction: Refer to the ICIS petrochemical product price index to establish a cost-plus pricing analysis model.

2. Account period combination design: adopt the step payment plan of “30% advance payment + 60% on bill of lading + 10% warranty” to reduce capital occupation.

Contract risk prevention and control system

1. Legal terms setting: According to the United Nations Convention on Contracts for the International Sale of Goods, clarify the scope of application of force majeure clauses.

2. Quality traceability mechanism: require suppliers to provide complete traceable batch records and retain samples for 3 years.

Digital logistics monitoring

1. Optimization of transportation schemes: compare the economic efficiency of sea transportation (cost reduction of 40%) and China-Europe Express (time efficiency improvement of 25%).

2. Internet of Things monitoring: use Freightos logistics tracking system to monitor transportation environment parameters such as temperature and humidity in real time.

Standardized process of arrival quality inspection

1. Implementation of sampling scheme: implement AQL 1.0 sampling plan in accordance with GB/T 2828.1-2012 standard.

2. Rapid detection technology: use near-infrared spectrometer for 3-minute rapid component analysis.

Supplier Performance Management

1. KPI Assessment System: Establish an evaluation model that includes indicators such as on-time delivery rate (weight 30%), quality qualification rate (25%), and price competitiveness (20%).

2. Continuous Improvement Mechanism: Hold a supplier conference every quarter to share industry trends and improvement requirements.

Sustainable Procurement Strategy

1. Circular Economy Practice: Give priority to PA6 products containing more than 30% recycled materials.

2. Carbon Footprint Management: Require suppliers to provide ISO 14067 carbon footprint certification to help companies build ESG.

Conclusion of Buying PA6

In the context of intensified global competition, scientific PA6 procurement has become an important part of the core competitiveness of enterprises. By building a procurement system that includes 10 modules such as demand analysis, intelligent sourcing, and risk control, enterprises can reduce procurement costs by an average of 15% and increase the on-time delivery rate to more than 98%. It is recommended that the procurement department establish a digital procurement platform to continuously track the development of PA6 modification technology, especially in the application innovation of emerging fields such as new energy vehicles and 5G communications. Contact Fuchen New Material Technology and we will provide you with a complete series of purchasing guides and suggestions.