NYLON 610 FEATURE

✔ High Bio-content

✔ Good Processability

✔ Good Chemical Resistance

✔ Low Water Absorption

✔ Good Dimensional Stability

Nylon 610 is a type of nylon known for its eco-friendly credentials. A significant portion of its raw materials come from renewable sources, making it a more sustainable choice compared to other nylons. But it doesn’t stop there! It boasts several other valuable properties.

One key feature is its low moisture absorption. This makes 610 dimensionally stable, meaning it retains its shape well even under varying environments. Additionally, it offers good resistance to a wide range of chemicals, making it suitable for demanding applications.

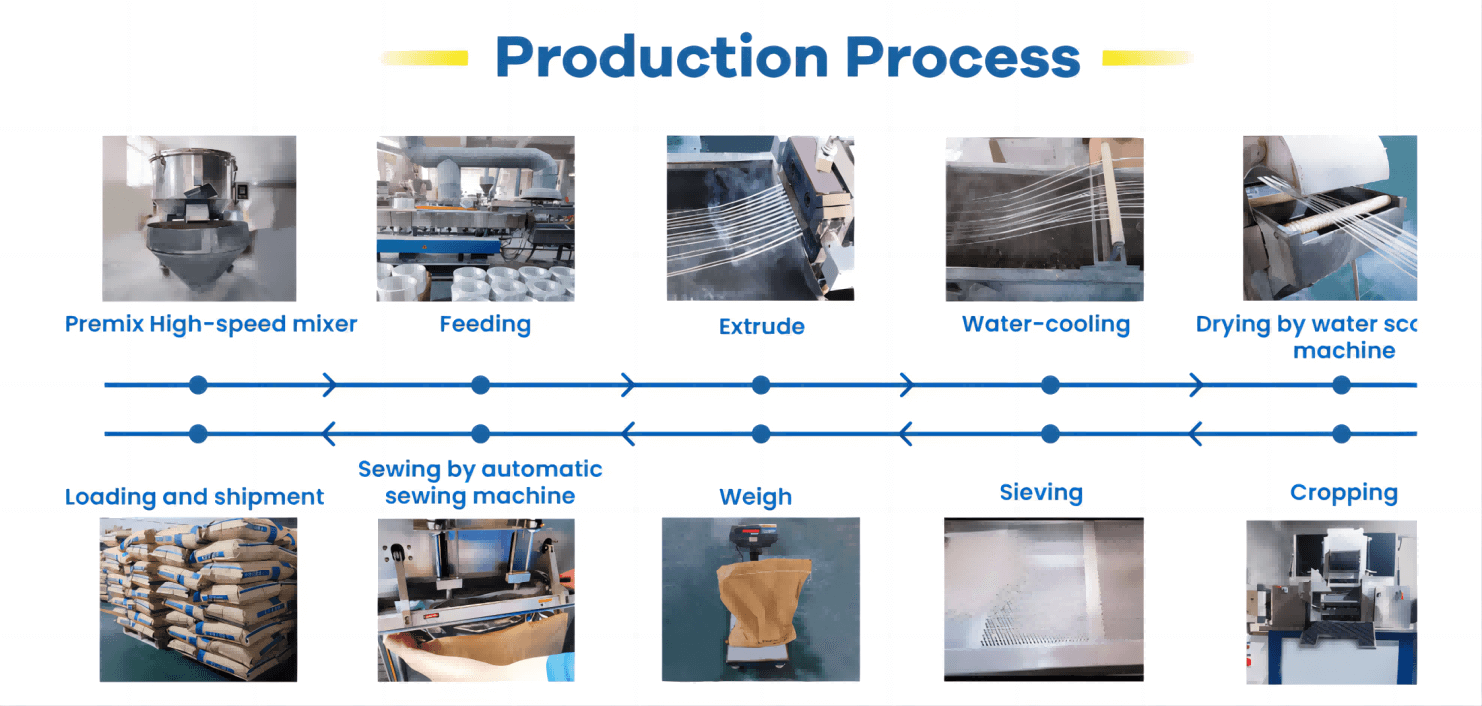

On the manufacturing side, it is easily processed using techniques like injection molding and extrusion. This translates to cost-effective production. Overall, the combination of sustainability, chemical resistance, good processability, and dimensional stability make PA610 a versatile material for a wide range of applications.

PA 610 Natural Resin is a bio-based nylon known for its eco-friendly properties, good dimensional stability, and ease of processing.

Similar to PA 610 Natural Resin, the Black version offers bio-content, good shape retention, and processability.

It is a bio-based nylon enhanced with 25% glass fiber for increased strength and stiffness compared to standard version.

It is a bio-based nylon reinforced with 30% glass fibers, making it even stronger and stiffer than PA 610 GF25 for demanding applications.

Nylon 610 is a type of engineering plastic belonging to the polyamide family, also known as nylons. It’s considered a hybrid material with properties that fall between commonly used nylons 6 and 12.

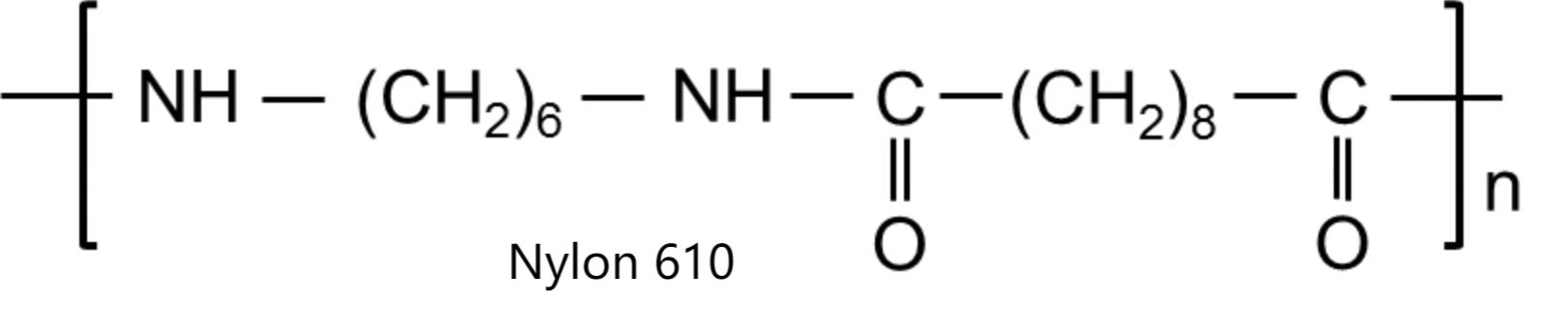

Nylon 610 is created through a chemical process called condensation polymerization, where sebacic acid and hexamethylenediamine are combined

Due to its toughness and balance of properties, it finds use in various applications, including:

No, Nylon 610 is distinct from other nylons like Nylon 6 and 12. While they share some general properties, it offers a specific set of characteristics that make it suitable for different applications.