Uvod

PA12 GF50, a glass-filled polyamide plastic, has emerged as a pivotal material in various industries, recognized for its robust properties and adaptability. This article delves into the unique composition and attributes of PA12 GF50, highlighting the myriad of sectors benefiting from its use.

What is PA12 GF50?

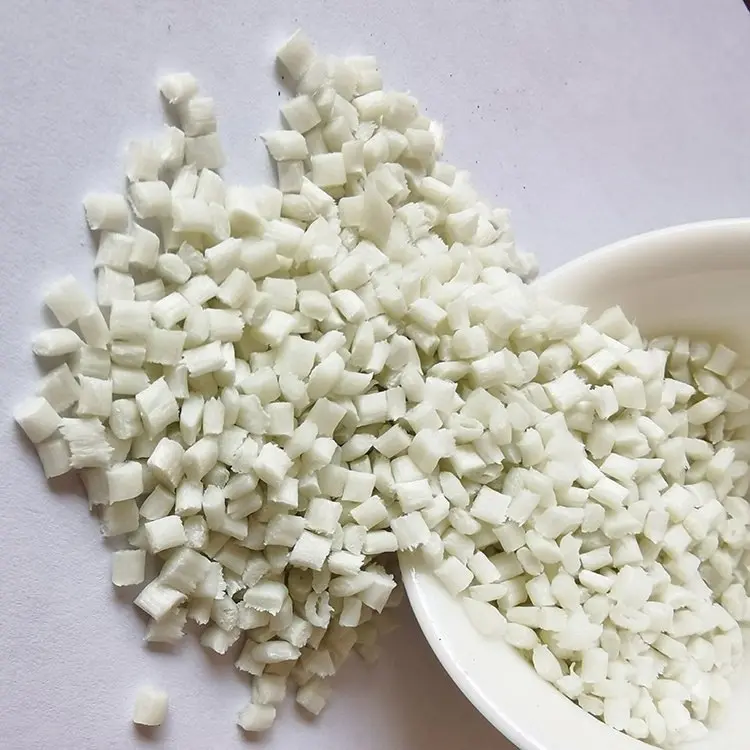

- A Superior Polyamide Plastic

PA12 GF50 is part of the polyamide family, renowned for their strength and durability. These synthetic resins are enhanced through the incorporation of glass fibers, marked by the “GF” in its name. This glass-filled reinforcement significantly boosts the material’s mechanical properties, making PA12-GF50 a prime choice for diverse applications.

- The Role of E-Glass Fibers

The glass fibers used in PA12-GF50 are typically E-glass, known for its excellent strength-to-weight ratio and corrosion resistance. When fused with the polyamide matrix, the composite material achieves remarkable mechanical properties, such as heightened tensile strength, impact resistance, and dimensional stability.

Key Benefits and Characteristics of PA12 GF50

- Exceptional Wear Resistance

One of the standout features of PA12-GF50 is its superior resistance to wear and abrasion. This quality makes it ideal for components that endure constant friction or contact, such as automotive gears, bearings, and bushings. These parts benefit from PA12-GF50’s durability, ensuring prolonged system reliability and performance.

- Vrhunska električna izolacija

PA12-GF50 also excels in providing electrical insulation. This property is crucial in the electronics sector, where components like connectors and switches must prevent short circuits and electrical failures. The high insulation capabilities of PA12-GF50 make it a preferred material for manufacturing such critical electronic components.

- Outstanding Chemical Resistance

The chemical resistance of PA12-GF50 is another significant advantage. It withstands a variety of chemicals and solvents, making it suitable for environments with harsh or corrosive conditions. Industries such as chemical processing and pharmaceuticals utilize PA12-GF50 for components that maintain integrity against aggressive chemicals over time.

- Excellent Dimensional Stability

Dimensional stability is another key attribute of PA12-GF50. It maintains its shape and size under varying conditions, a crucial requirement in precision-dependent sectors like aerospace and medical device manufacturing. Components made from PA12-GF50 adhere to strict dimensional tolerances, ensuring that the final products meet stringent specifications.

Industrial Applications OF PA12 GF50

- Avtomobilska industrija

In the automotive industry, PA12-GF50’s wear resistance and durability are invaluable. It is widely used to manufacture components like gears, bearings, and bushings, which are essential for the longevity and efficiency of automotive systems.

- Electronics Sector

PA12 -GF50’s electrical insulation properties make it an indispensable material in the electronics industry. It is used in creating connectors, switches, and other components where high insulation is critical to prevent electrical failures.

- Chemical Processing and Pharmaceuticals

Due to its robust chemical resistance, PA12-GF50 is ideal for applications in chemical processing and pharmaceutical industries. Components exposed to corrosive chemicals can rely on PA12-GF50 to maintain their structural integrity over extended periods.

- Aerospace and Medical Devices

In aerospace and medical device manufacturing, where precision is paramount, PA12-GF50’s dimensional stability ensures that components meet exacting standards. This stability is crucial for the safety and effectiveness of aerospace equipment and medical devices.

Conclusion of PA12 GF50

PA12 GF50 stands out as a versatile and high-performance material, integral to many industries, including automotive, electronics, chemical processing, aerospace, and medical devices. Its unique combination of mechanical strength, electrical insulation, chemical resistance, and dimensional stability makes it indispensable for producing durable, reliable, and precise components. As technological advancements progress, PA12 -GF50’s role in developing innovative solutions is set to expand, further cementing its importance across various fields.

FAQ: Understanding the Applications and Benefits of PA12 GF50

1.What is PA12 GF50?

PA12-GF50 is a type of polyamide plastic reinforced with glass fibers. The “PA12” refers to the polyamide resin, and “GF50” indicates that it contains 50% glass fibers by weight. This combination gives the material enhanced strength, durability, and resistance to wear, making it suitable for a variety of industrial applications.

2.Why is PA12 GF50 considered superior to other materials?

PA12-GF50 offers several advantages:

- High Tensile Strength and Impact Resistance: The addition of glass fibers boosts the material’s mechanical properties, making it robust against physical stresses.

- Odpornost na obrabo in abrazijo: It performs well in environments where components experience constant friction or contact.

- Električna izolacija: It provides excellent insulation properties, crucial for electronic applications.

- Kemijska odpornost: PA12-GF50 resists degradation from many chemicals and solvents, making it ideal for harsh environments.

- Dimenzijska stabilnost: It maintains its shape and size under various conditions, essential for precision parts.

3.What are the primary industries that use PA12 GF50?

- Avtomobilska industrija: Used for making gears, bearings, and bushings due to its wear resistance and durability.

- Electronics Sector: Utilized in connectors, switches, and other components requiring high electrical insulation.

- Chemical Processing and Pharmaceuticals: Valued for its chemical resistance in handling corrosive substances.

- Aerospace and Medical Devices: Preferred for its dimensional stability, ensuring precision in critical components.

4.How do the glass fibers enhance PA12 GF50’s properties?

The glass fibers, typically E-glass, provide a significant boost to the material’s mechanical properties. They offer:

- Increased Tensile Strength: Enhancing the material’s ability to withstand pulling forces.

- Improved Impact Resistance: Making the material less likely to break or deform under sudden impacts.

- Better Dimensional Stability: Helping the material maintain its form and dimensions under stress and temperature changes.

5. What makes PA12 GF50 suitable for electrical insulation?

PA12-GF50’s composition allows it to provide superior electrical insulating properties, which are essential in preventing electrical failures and short circuits. This makes it a preferred choice for components in the electronics industry that require reliable insulation.

6. Can PA12 GF50 withstand harsh chemicals and environments?

Yes, PA12-GF50 is known for its excellent chemical resistance. It can endure exposure to a variety of chemicals and solvents without degrading, making it ideal for applications in chemical processing and environments with corrosive substances.

7. How does PA12 GF50 ensure precision in aerospace and medical device applications?

PA12-GF50’s excellent dimensional stability ensures that components maintain their exact size and shape under different conditions. This property is critical in aerospace and medical device manufacturing, where precision and adherence to tight tolerances are paramount.

8. What future roles might PA12 GF50 play in industrial applications?

As technology evolves and industries seek more durable and reliable materials, PA12-GF50 is expected to play an increasingly important role. Its combination of strength, resistance, and stability makes it ideal for developing innovative products and solutions across various sectors.

9. How does PA12 GF50 contribute to product longevity and reliability?

PA12-GF50’s wear resistance, impact strength, and stability under various conditions contribute significantly to the longevity and reliability of the components made from it. This makes it a preferred material for critical parts that must perform consistently over time.

10. Why choose PA12 GF50 for industrial applications?

Choosing PA12-GF50 for industrial applications means opting for a material that provides superior mechanical strength, excellent electrical insulation, robust chemical resistance, and precise dimensional stability. These attributes make it suitable for a wide range of demanding applications across multiple industries.