Have you ever wondered what those handy shopping bags you get at the store are made from? Well, there’s a good chance it’s nylon! Nylon is a versatile material crafted from combining molecules into various shapes, like fibers or films. It’s used in many different industries. But What is Nylon 6 10? This article will delve into the specifics of nylon 6 10, its properties, and its many applications.

What is Nylon 6 10?

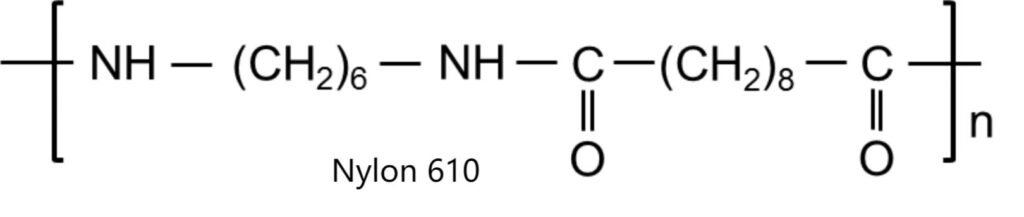

Imagine nylon 6 10 as a type of nylon built from two building blocks called monomers. The numbers 6 and 10 refer to the number of carbon atoms in each monomer. In nylon 6 10, one building block has 10 carbon atoms and is called sebacoyl chloride. The other has 6 carbon atoms and is called 1,6-diaminohexane.

When these two monomers link up in a chemical reaction, they form a long chain, which is what nylon 6 10 is. This process is called condensation polymerization, and during this reaction, some small molecules are lost. Just like other nylons, nylon 6/10 can be strengthened with glass fibers or other materials to improve its performance.

Nylon 6 10 Structure

How Does Nylon 6/10 Compare?

Compared to other nylons, nylon 6/10 has some distinct advantages. A key benefit is that it absorbs very little moisture, allowing it to stay strong even when wet. This makes it a great choice for things like toothbrush bristles. Another plus is that nylon 6/10 handles temperature changes better than some other nylons, and it also resists many chemicals.

Here are two additional features of Nylon 6/10:

- Good Abrasion Resistance:Nylon 6/10 has a high resistance to wear and tear from friction. This makes it suitable for applications that involve sliding or rubbing motions, such as bearings, gears, and bushings.

- Flame Retardant Properties:Certain formulations of nylon 6/10 can be inherently flame retardant or can be modified with additives to achieve this property. This makes it a valuable material for applications where fire safety is a concern, such as in electrical components or mass transportation parts.

The Pros and Cons of Nylon 6/10

Pros:

- Low moisture absorption

- Maintains strength over a wide temperature range

- Good resistance to chemicals

- Good abrasion resistance

- Flame retardant properties (in some formulations)

Con:

- Generally more expensive than some other nylons

Where Can You Find Nylon 6 10?

The benefits of nylon 6/10 make it a valuable material in many industries. As mentioned before, its low moisture absorption makes it perfect for toothbrush bristles. Additionally, because it stays strong under varying temperatures, it’s widely used in car parts like engine covers, air intakes, and radiators. The good chemical resistance of nylon 6/10 also makes it suitable for fuel tanks.

Beyond cars, the sporting world makes use of nylon 6/10 in things like racket frames and bicycle parts. Its toughness and lightweight properties make it ideal for these applications, helping to extend the life of sports equipment and reduce weight for athletes.

The excellent mechanical properties and wear resistance of nylon 6/10 also make it a go-to material for machine parts in heavy industries, such as gears, bearings, and gyroscopes. In the world of electronics, its good electrical insulation properties make it useful for connectors and insulators.

In Conclusion

The world of nylons is vast, and nylon 6 10 stands out with its impressive combination of low moisture absorption, good temperature resistance, chemical resistance, abrasion resistance, and even flame retardant properties (in some formulations). These features make it a valuable material across various industries, from sporting goods to automobiles and electronics. So, the next time you encounter a durable and versatile plastic component, there’s a good chance it might be nylon 6/10!