Introduction

Polyamide 11, commonly referred to as PA 11, is a high-performance thermoplastic resin derived from renewable resources. Unlike traditional petroleum-based nylons, PA 11 is derived from castor oil, making it an eco-friendly option for industries seeking sustainable solutions. Known for its resilience, durability, and versatility, PA11 has found applications in industries ranging from automotive to aerospace and medical technology. This article explores the history, unique properties, applications, and advantages of PA11, alongside a comparison with other common polyamides and an FAQ section for those considering this material for various applications.

What is PA 11?

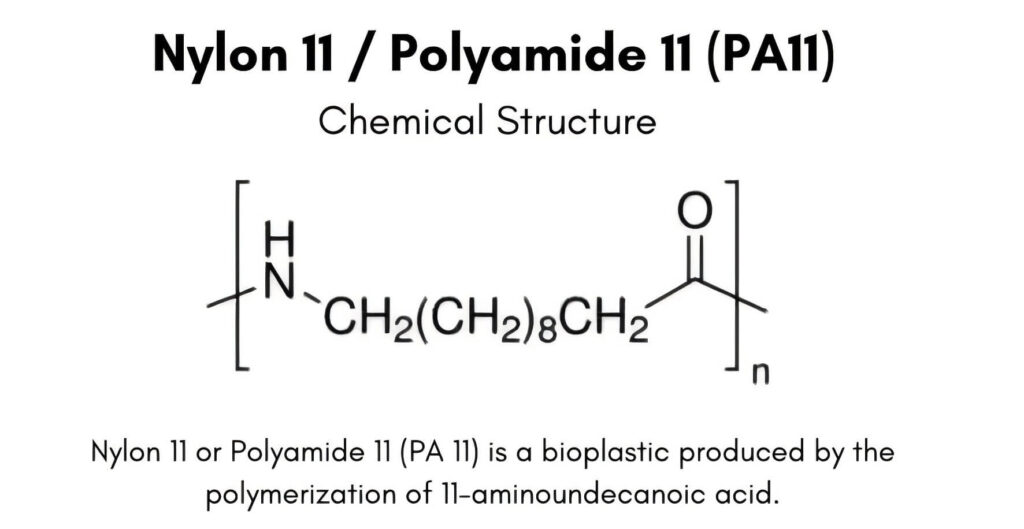

PA 11 is a bio-based polymer in the polyamide family, known for its balance of mechanical strength, flexibility, and chemical resistance. It offers a sustainable alternative to traditional polymers like nylon 6 and nylon 66, which are petroleum-derived. The use of castor oil as a raw material not only reduces the dependency on fossil fuels but also enhances PA 11’s properties for specific applications that require strength, impact resistance, and flexibility under extreme conditions.

Historical Development of PA 11

PA11 was first proposed in 1938, drawing inspiration from the pioneering work of Wallace Carothers. Thann & Joseph Zeltner in Mulhouse, France, developed a process to convert castor oil into 11-aminoundecanoic acid, which is the monomer for PA 11. Here’s a timeline of PA11’s development and evolution:

- 1940:Michel Genas and Marcel Kastner succeeded in converting castor oil into 11-aminoundecanoic acid.

- 1947:The first patents for PA11 were filed, leading to its commercial production.

- 1950s:The first PA11 yarn was produced, and industrial-scale production began in Marseilles.

- 1960s:PA11 gained popularity in the automotive and medical sectors.

- 1970s-1980s:PA11 expanded into household products, sports equipment, and even aerospace applications.

- 1990s-2000s:With further technological advances, PA11 found new applications in electronics, optics, energy, and environmental industries.

- Present Day:PA 11 remains a key material due to its balance of performance and sustainability, and it continues to support industrial and consumer applications worldwide.

Key Properties of PA 11

PA 11 exhibits several notable properties that make it a superior choice in many applications:

- High Tensile Strength: Provides outstanding durability, allowing it to withstand mechanical stress and deformation.

- Temperature Resistance: Remains stable up to 150°C, suitable for applications requiring thermal stability.

- Chemical Resistance: Resistant to many chemicals, including acids, alkalis, and solvents, making it ideal for industrial environments.

- Low Moisture Absorption: Unlike other nylons, PA 11 absorbs minimal moisture, reducing the risk of dimensional changes and mechanical property loss in humid conditions.

- Eco-Friendliness: Made from renewable castor oil, PA 11 is biodegradable and has a lower carbon footprint than petroleum-based nylons.

- Abrasion Resistance: Provides superior wear resistance, suitable for components subject to friction.

Advantages and Disadvantages of PA 11

While PA 11 offers numerous benefits, there are some drawbacks to consider:

Advantages:

- Renewable Source: Unlike nylon 6 or nylon 66, PA 11 is derived from castor oil, making it a more sustainable choice.

- Durability: Resistant to abrasion and impact, making it suitable for high-wear environments.

- Low-Temperature Performance: Functional in temperatures as low as -40°C, ideal for cold applications.

- Recyclability: PA 11 can be recycled, contributing to its eco-friendly profile.

Disadvantages:

- Cost: PA 11 can be more expensive than petroleum-derived alternatives due to its renewable sourcing.

- Thermal Conductivity: It has low thermal conductivity, limiting its use in heat-transfer applications.

- Electrical Conductivity: Due to its poor electrical conductivity, PA11 may not be suitable for certain electronics without modifications.

Applications of PA 11

PA 11 is utilized across a variety of sectors due to its unique combination of properties:

- Automotive Industry: Used in fuel lines, brake lines, and air conditioning systems, PA11 offers durability and chemical resistance.

- Aerospace: Used in lightweight components that require resilience to temperature and stress, as well as insulation materials.

- Medical Devices: Suitable for catheters, tubing, and other medical devices due to its biocompatibility and chemical resistance.

- Textiles and Consumer Goods: Common in fabrics and fibers, PA11 is used in sportswear, protective gear, and durable clothing.

- Energy and Environmental Technology: Ideal for flexible pipelines, cable sheathing, and renewable energy systems, providing a reliable material for the energy sector.

PA 11 vs. Other Nylons: A Comparative Overview

While PA 11 shares many characteristics with nylon 6 and nylon 66, it offers distinct advantages in specific areas:

- Moisture Absorption: PA11 absorbs less water than nylon 6 or nylon 66, enhancing dimensional stability.

- Environmental Impact: PA11’s castor oil base offers a lower environmental impact.

- Durability: Although nylon 66 is often preferred for its strength, PA11 offers a good balance of strength and flexibility.

FAQs about PA 11

Q: What is PA11 made from?

A: PA11 is derived from castor oil, making it a bio-based polymer with a smaller environmental footprint compared to petroleum-based polyamides.

Q: Is PA11 biodegradable?

A: While PA11 is not entirely biodegradable, it is recyclable, and its renewable sourcing contributes to its eco-friendliness.

Q: How does PA11 perform in extreme temperatures?

A: PA11 is highly resistant to both high and low temperatures, operating effectively from -40°C to 150°C, making it suitable for extreme environments.

Q: Can PA11 be used in medical applications?

A: Yes, PA11’s chemical resistance and biocompatibility make it a popular choice for medical devices and components in contact with bodily fluids.

Q: How does PA11 compare to other bio-based plastics?

A: PA11 offers a unique combination of mechanical strength and durability that sets it apart from other bio-based plastics, many of which may not match its performance under stress or temperature fluctuations.

Conclusion

PA 11 represents a blend of sustainability and high performance, bridging the gap between environmentally friendly materials and industrial-grade durability. Its unique properties, such as high chemical resistance, low moisture absorption, and stability across extreme temperatures, make it invaluable across automotive, aerospace, medical, and environmental industries. As demands for sustainable materials continue to grow, PA11’s role is likely to expand even further, shaping the future of renewable polymers in industrial applications. Whether you’re considering PA11 for its mechanical attributes or eco-friendly nature, it offers a versatile and reliable solution for diverse applications.