Introduction

In the world of 3D printing, one material stands out for its versatility and strength: nylon. Whether you’re working on functional prototypes, engineering parts, or artistic creations, nylon offers an incredible balance of durability, flexibility, and impact resistance. However, achieving high-quality prints with nylon requires more than just the right filament – it hinges on perfecting one crucial factor: temperature.

For many users, the correct nylon printing temperature is often an elusive concept. Too high or too low, and your print quality can suffer dramatically. If you’re struggling with inconsistent results, poor adhesion, or weakened prints, adjusting your print temperature could be the game-changer you need. In this guide, we’ll dive deep into the significance of temperature in nylon 3D printing, explore the optimal temperature ranges for different nylon filaments, and provide practical insights into solving common issues related to incorrect temperature settings. By the end, you’ll not only understand the science behind nylon printing temperatures but also how to achieve professional-level prints in your 3D printing journey.

Understanding the Importance of Nylon Printing Temperature

Why is temperature so critical in nylon 3D printing?

Nylon, a synthetic polymer known for its resilience and thermal properties, requires a specific melting point to flow smoothly through a 3D printer’s hotend. When the filament is heated too much, it can break down or over-extrude, compromising the print quality. On the other hand, too little heat can cause poor adhesion between layers, leading to cracking, warping, and reduced strength.

At the core of 3D printing is the extrusion process—where the filament is heated to a point just beyond its melting temperature so that it can be deposited layer by layer. For nylon, this delicate balance must be struck with precision. The correct print temperature ensures:

- Good layer bonding: Each layer needs to fuse properly to the previous one for strong, cohesive prints.

- Smooth extrusion: The filament should flow freely through the nozzle without clogging or inconsistent extrusion.

- Durable prints: Nylon’s inherent strength comes from how well each layer adheres to the next. A slight error in temperature can result in weakened bonds and compromised print durability.

The printing temperature you choose also affects the viscosity of the material, making it easier or harder for the filament to flow through the nozzle. If the filament is too thick or too thin, the results can be dramatic—either in the form of poor adhesion or excessive stringing and oozing.

What Are the Ideal Temperature Ranges for Nylon Printing?

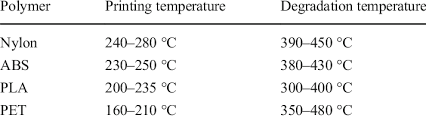

The optimal temperature for nylon printing can vary depending on the type of nylon filament, the 3D printer model, and even the environmental conditions. However, as a general rule of thumb, the optimal extrusion temperature for most nylon filaments is between 240°C to 270°C.

Here’s a breakdown of ideal printing temperature ranges for different types of nylon filaments:

Standard Nylon (e.g., Nylon 6, Nylon 66):

This is the most commonly used nylon for 3D printing. Its melting point typically ranges between 245°C to 265°C. This type of nylon benefits from higher extrusion temperatures due to its denser molecular structure, which ensures stronger and more durable prints.Nylon 12:

Nylon 12 is a softer and more flexible filament compared to other nylon types. It generally prints best at 240°C to 250°C, making it a great choice for functional parts that need some flexibility, such as brackets, clips, or joints.Nylon Composites (e.g., carbon fiber-filled, glass-filled):

If you’re using composite nylons, such as those blended with carbon fiber or glass, these often require higher temperatures for smooth extrusion. A good temperature range for these would be 250°C to 270°C to ensure that the composite materials bond correctly and don’t clog the nozzle.

Pro Tip:

Always consult the manufacturer’s guidelines for the specific filament you’re using. Filament compositions can vary greatly, so what works for one brand might not work for another. Conducting small test prints can help you fine-tune your temperature settings.

Factors Affecting the Optimal Temperature

The temperature for nylon printing isn’t just determined by the filament itself. Several external factors influence the ideal printing conditions. These include:

Printer Type and Hotend Capability:

Not all 3D printers are designed to handle high temperatures. Some budget models may struggle to maintain stable temperatures at higher levels. Ensure your printer is capable of reaching the required temperature range and maintaining that stability throughout the print.Ambient Temperature and Humidity:

While nylon is highly sensitive to temperature, it’s also affected by the surrounding environment. High humidity can cause nylon to absorb moisture, which will lower the filament’s melting point, making it more challenging to print. For the best results, store your nylon filament in a dry place or use a filament dryer before printing.Build Plate Temperature:

For optimal adhesion, the build plate temperature should be 70°C to 90°C. Nylon prints tend to warp as they cool down, so a heated bed helps mitigate this issue and promotes better adhesion to the build surface.Speed and Layer Height:

Higher printing speeds can require slightly higher temperatures to ensure consistent extrusion. Additionally, thicker layers may need higher extrusion temperatures to achieve a smooth surface finish.

Troubleshooting Common Nylon Printing Temperature Issues

Despite best efforts, temperature-related issues can still arise during nylon printing. Here are a few common problems and solutions:

1. Poor Adhesion or Warping

- Problem: When the temperature is too low, the layers of the nylon printing might not bond well, leading to poor adhesion to the build plate and warping.

- Solution: Increase the extrusion temperature slightly. Additionally, ensure the print bed is heated to around 70°C–90°C. For better adhesion, consider using a special build surface like a Garolite or Kapton tape.

2. Stringing or Oozing

- Problem: If the print temperature is too high, the nylon may become too runny, leading to unwanted strings and blobs of material.

- Solution: Lower the temperature in increments of 5°C and enable retraction settings in your slicer software to prevent the filament from oozing during travel movements.

3. Print Failures or Layer Delamination

- Problem: A too-low printing temperature can cause incomplete extrusion or layer separation.

- Solution: Increase the printing temperature to improve flow. Additionally, check the nozzle for any blockages that may be limiting the filament’s flow.

4. Nozzle Clogs

- Problem: If the temperature is set too low, the filament may solidify prematurely inside the nozzle, causing a blockage.

- Solution: Raise the printing temperature slightly and run a cleaning filament through the hotend to clear any obstructions.

FAQs About Nylon Printing Temperature

1. What happens if the temperature for nylon printing is too high or too low?

- Too high: Excessive temperature can cause nylon to degrade, resulting in weak or brittle prints. It may also lead to excessive stringing and oozing.

- Too low: Insufficient temperature causes poor adhesion between layers, leading to warping, delamination, and brittle prints.

2. How can I determine the optimal printing temperature for my specific nylon filament?

- Test Prints: Run small test prints with different temperature settings. Adjust in small increments (5°C) until you achieve the desired result.

- Manufacturer Guidelines: Always start with the manufacturer’s recommended temperature range and adjust based on your printer and environmental conditions.

3. Can I adjust the temperature during the printing process?

Yes! Many slicer programs allow you to adjust the printing temperature layer by layer, making it easier to experiment with different temperatures as your print progresses.

Conclusion

Mastering the optimal temperature for nylon printing is essential for achieving the best possible results. With the right temperature, you can ensure smooth extrusion, strong layer adhesion, and durable prints. By understanding the factors that affect the ideal printing temperature and troubleshooting common issues, you’ll be able to avoid frustrating print failures and produce high-quality parts with ease.

Whether you’re printing functional prototypes, mechanical parts, or artistic designs, the temperature of your nylon filament will make a world of difference. By experimenting, fine-tuning, and considering your printer’s capabilities, you’ll unlock the full potential of nylon and elevate your 3D printing experience to a whole new level.

Remember, 3D printing is as much an art as it is a science. With patience and attention to detail, the perfect nylon print is within your reach.