Τι είναι τα πολυαμίδια βραχείας και μακράς αλυσίδας

Τα πολυαμίδια με λιγότερα από 10 άτομα άνθρακα στις αλυσίδες τους αναφέρονται γενικά ως πολυαμίδια μικρής αλυσίδας (ή νάιλον μικρής αλυσίδας), όπως το πολυαμίδιο 6 (PA6), το πολυαμίδιο 66 (PA66) και το πολυαμίδιο 46 (PA46). Τα πολυαμίδια με 10 ή περισσότερα άτομα άνθρακα στις αλυσίδες τους ονομάζονται πολυαμίδια μακράς αλυσίδας (ή νάιλον μακράς αλυσίδας), όπως το πολυαμίδιο 610 (PA610), το πολυαμίδιο 612 (PA612), το πολυαμίδιο 1012 (PA1012) και το πολυαμίδιο 12 (PA12). Λόγω της χαμηλότερης περιεκτικότητας σε αμιδικούς δεσμούς στα πολυαμίδια μακράς αλυσίδας, έχουν χαμηλότερη απορρόφηση νερού, καλύτερη σταθερότητα διαστάσεων και καλύτερη ολκιμότητα σε σύγκριση με τα πολυαμίδια μικρής αλυσίδας.

PA12 Εφαρμογές και εναλλακτικές λύσεις

Το PA12, ένας τύπος πολυαμιδίου μακράς αλυσίδας, χρησιμοποιείται κυρίως σε εξαρτήματα αυτοκινήτων, στην τρισδιάστατη εκτύπωση, σε μηχανήματα και στην αεροδιαστημική. Στα εξαρτήματα αυτοκινήτων, το ενισχυμένο με ίνες γυαλιού (GF) PA12 χρησιμοποιείται κυρίως σε συστήματα γραμμών καυσίμου, συστήματα εξάτμισης αυτοκινήτων και ταχυσυνδέσμους. Επί του παρόντος, η τεχνολογία για τη χύτευση με έγχυση του PA12 και των τροποποιημένων υλικών του ανήκει κυρίως σε ξένες εταιρείες τροποποίησης, όπως η Arkema στη Γαλλία, η Evonik στη Γερμανία και η Ube Industries στην Ιαπωνία. Αν και έχει διεξαχθεί εγχώρια έρευνα για τις ρητίνες PA12 και τα τροποποιημένα υλικά τους, δεν υπάρχει ακόμη βιομηχανική παραγωγή ρητινών PA12 στην Κίνα. Ως εκ τούτου, η τιμή των υλικών PA12 στην Κίνα εξακολουθεί να είναι πολύ υψηλή, επομένως η έρευνα και η ανάπτυξη εναλλακτικών υλικών PA12 έχει σημαντική πρακτική σημασία. Επιπλέον, τα πολυαμίδια μακράς αλυσίδας που παράγονται από υλικά μερικώς ή πλήρως βιολογικής προέλευσης, όπως τα PA610, PA612 και PA1012, έχουν περιβαλλοντικά πλεονεκτήματα σε σχέση με το PA12, το οποίο προέρχεται από μη ανανεώσιμα ορυκτά καύσιμα.

Fuchen Νέο υλικό's Research

Η Fuchen New Material συνέκρινε τις ιδιότητες τριών υλικών: GF30, PA1012 και PA12, όλα με περιεκτικότητα σε ίνες γυαλιού 30%. Διενεργήθηκε επίσης δοκιμαστική παραγωγή στο καλούπι ενός ταχυσύνδεσμου γραμμής καυσίμου αυτοκινήτου μαζικής παραγωγής για να συγκριθεί η απόδοση αυτών των υλικών. Η έρευνα αυτή παρέχει μια βάση για την επακόλουθη ανάπτυξη εναλλακτικών υλικών σε σχέση με τα υλικά PA12/GF30, χρησιμοποιώντας άλλους τύπους ενισχυμένων πολυαμιδίων μακράς αλυσίδας.

Περίληψη των βασικών σημείων

(1) Η αντοχή σε εφελκυσμό, η αντοχή σε κάμψη και το μέτρο ελαστικότητας κάμψης των υλικών PA612/GF30 είναι τα καλύτερα, ακολουθούμενα από τα υλικά PA1012/GF30, και τα χειρότερα είναι τα υλικά PA12/GF30.Ωστόσο, είτε πρόκειται για την αντοχή σε κρούση εγκοπής σε θερμοκρασία δωματίου είτε σε χαμηλή θερμοκρασία, το υλικό PA1012/GF30 είναι το καλύτερο, το υλικό PA12/GF30 είναι το δεύτερο και το υλικό PA612/GF30 είναι το χειρότερο.

(2) Η σειρά της πυκνότητας του υλικού, της θερμοκρασίας θερμικής παραμόρφωσης και του σημείου τήξης από το υψηλό στο χαμηλό είναι: Το ποσοστό συρρίκνωσης των τριών ενισχυμένων με GF πολυαμιδίων μακράς αλυσίδας είναι το ίδιο και το ποσοστό απορρόφησης νερού είναι χαμηλό, το οποίο δεν διαφέρει πολύ, αλλά η εμφάνιση των προϊόντων που εγχέονται από το υλικό PA1012/GF30 είναι καλύτερη από εκείνη του PA612/GF30.

(3) Με βάση την απόδοση του υλικού και την κατάσταση της χύτευσης με έγχυση, το υλικό PA1012/GF30 είναι η πιο οικονομική εναλλακτική λύση σε σχέση με το υλικό PA12/GF30.

Προετοιμασία υλικού

Οι πρώτες ύλες PA612 και PA1012 ξηράνθηκαν στους 100 ℃ για 4 ώρες και τα σχετικά υλικά ζυγίστηκαν σύμφωνα με την αναλογία των κλασμάτων μάζας της μήτρας ρητίνης, του GF και του αντιοξειδωτικού 69,8% και 30% 0,2%, αντίστοιχα. Η ρητίνη και το αντιοξειδωτικό προστέθηκαν πρώτα στον κατακόρυφο αναμικτήρα και αναμείχθηκαν ομοιόμορφα και στη συνέχεια προστέθηκαν στον εξωθητή διπλής κοχλίας διπλής κατεύθυνσης. Λιώστε και συμπιέστε έξω, το GF προστίθεται με πλευρική τροφοδοσία. στη συνέχεια, οι εξωθημένες λωρίδες ψύχονται με νερό και ξηραίνονται με στεγνωτήρα μαλλιών και τα σφαιρίδια κοκκοποιούνται με κοκκοποιητή. η θερμοκρασία του τμήματος τροφοδοσίας του εξωθητή είναι 230 ~ 250 ℃, η θερμοκρασία του τμήματος τήξης είναι 210 ~ 230 ℃, η θερμοκρασία του τμήματος κεφαλής είναι 230 ~ 250 ℃ και η ταχύτητα του κεντρικού κοχλία είναι 350 ~ 380r / h.

Αφού στεγνώσουν τα παρασκευασμένα σφαιρίδια, παρασκευάζεται μια τυπική σφήνα με μηχανή χύτευσης με έγχυση.Η θερμοκρασία είναι 230~260℃, η αποσυμπίεση είναι 80mpa και ο χρόνος είναι 35s.Ρίξτε το P12/GF30 στους 100℃ για 4 ώρες.

Κύρια αποτελέσματα

(1) Μηχανικές ιδιότητες

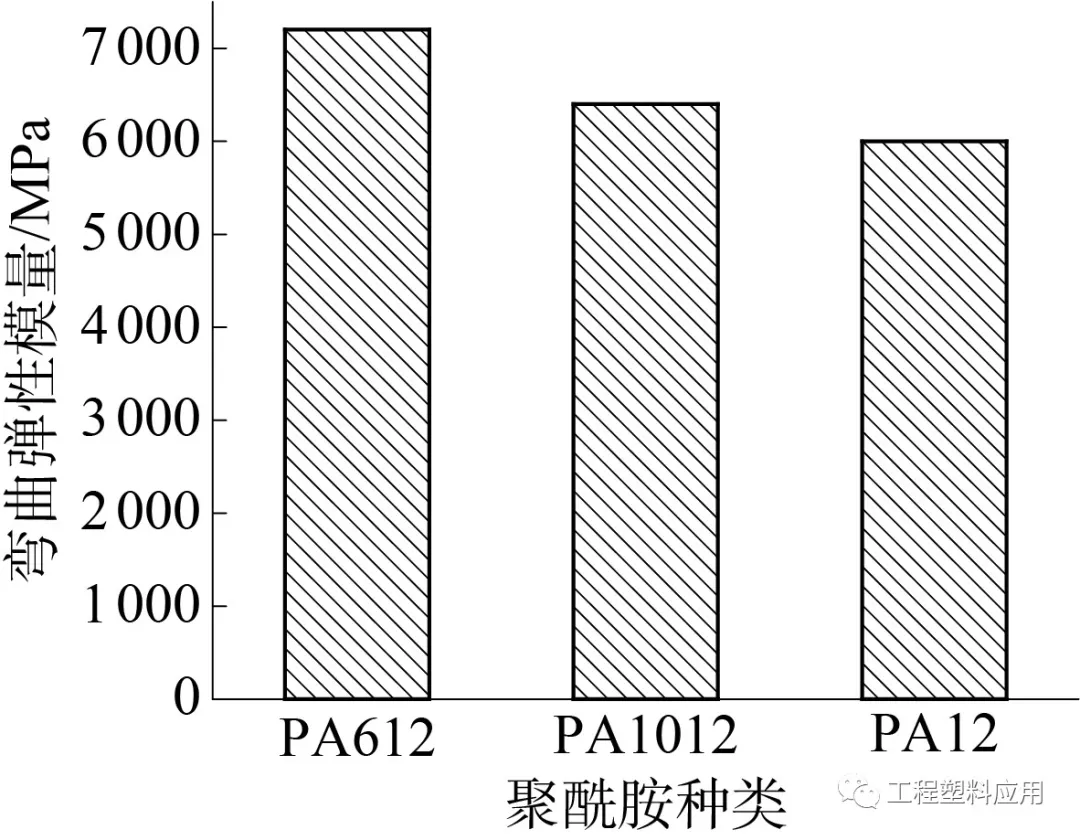

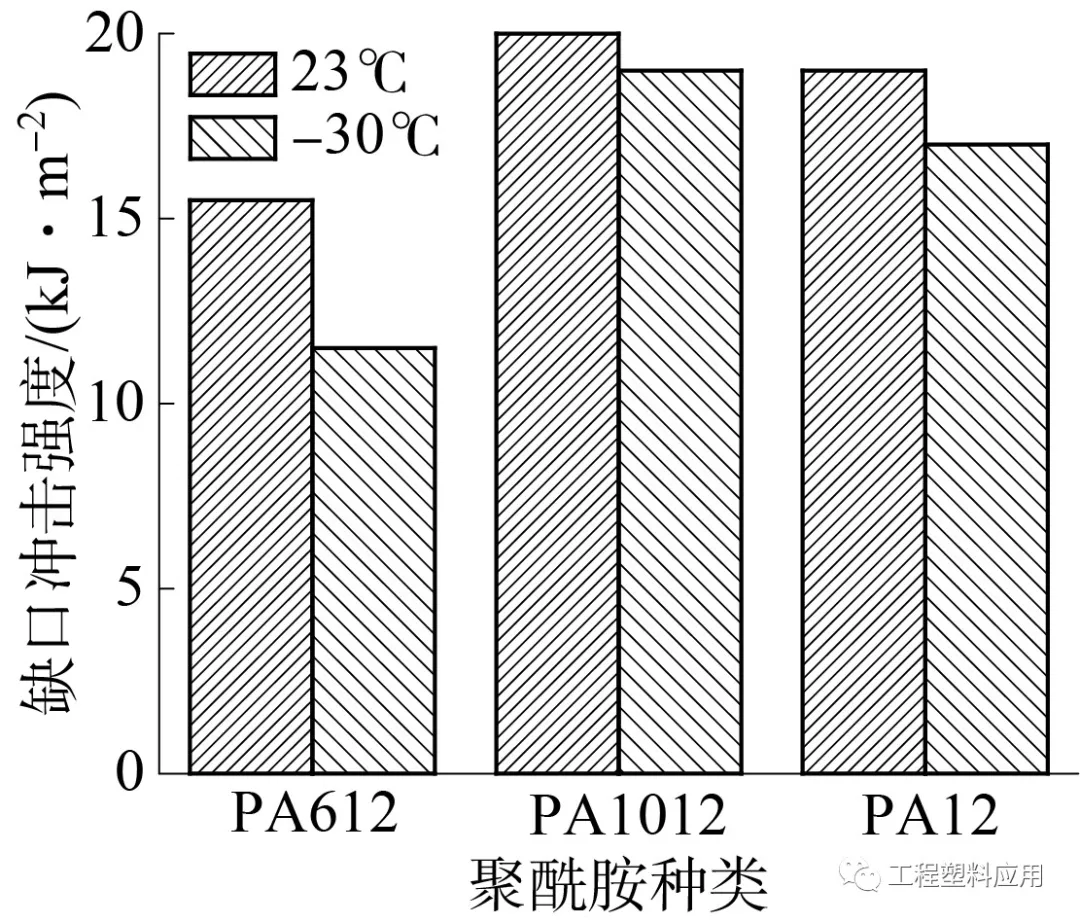

Η παρακάτω εικόνα δείχνει την απόδοση αύξησης της δύναμης που περιγράφεται από το GF.Η αντοχή σε εφελκυσμό, η αντοχή σε κάμψη και το μέτρο ελαστικότητας σε κάμψη των υλικών PA612/GF30 είναι τα καλύτερα, ακολουθούμενα από τα υλικά PA1012/GF30 και τα χειρότερα είναι τα υλικά PA12/GF30.Η αντοχή σε εφελκυσμό, η αντοχή σε κάμψη και το μέτρο ελαστικότητας σε κάμψη του υλικού PA612/GF30 είναι 50, 50MPa και 1 200 MPa υψηλότερα από αυτά του υλικού PA12/GF30, αντίστοιχα.Η αντοχή σε εφελκυσμό, η αντοχή σε κάμψη και το μέτρο ελαστικότητας σε κάμψη του υλικού PA1012/GF30 είναι 16, 15Mpa και 400MPa υψηλότερα από εκείνα του υλικού PA12/GF30, αντίστοιχα.Ωστόσο, είτε πρόκειται για την αντοχή σε κρούση εγκοπής σε θερμοκρασία δωματίου είτε σε χαμηλή θερμοκρασία, το υλικό PA1012/GF30 είναι το καλύτερο, το υλικό PA12/GF30 είναι το δεύτερο και το PA612/GF30 είναι το χειρότερο.

Σύγκριση ελαστικού συντελεστή κάμψης

Σύγκριση αντοχής σε κάμψη

Σύγκριση αντοχής σε κρούση με εγκοπή

Σύγκριση αντοχής σε εφελκυσμό

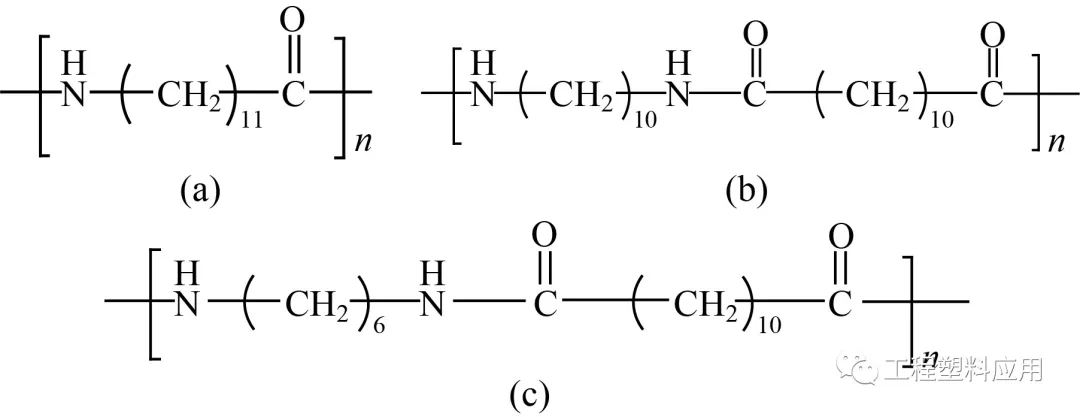

Η GF ενισχύει τις διαφορές στην απόδοση των διαφορετικών πολυαμιδίων μακράς αλυσίδας που οφείλονται κυρίως στις διαφορετικές μοριακές δομές των πολυαμιδίων μακράς αλυσίδας.Η μοριακή δομή των διαφορετικών πολυαμιδίων μακράς αλυσίδας φαίνεται στο παρακάτω σχήμα.Καθώς αυξάνεται η περιεκτικότητα της αμιδικής ομάδας, αυξάνεται η συμμετρία της μοριακής αλυσίδας και αυξάνεται η κρυσταλλικότητα, αυξάνεται επίσης η αντοχή της.Αντίθετα, καθώς μειώνεται η περιεκτικότητα της αμιδικής ομάδας (αύξηση της μεθυλικής ομάδας στη μοριακή αλυσίδα του πολυαμιδίου), η αντοχή μειώνεται σταδιακά και αυξάνεται η συμμόρφωση.

a—PA12;b—PA1012;c—PA612

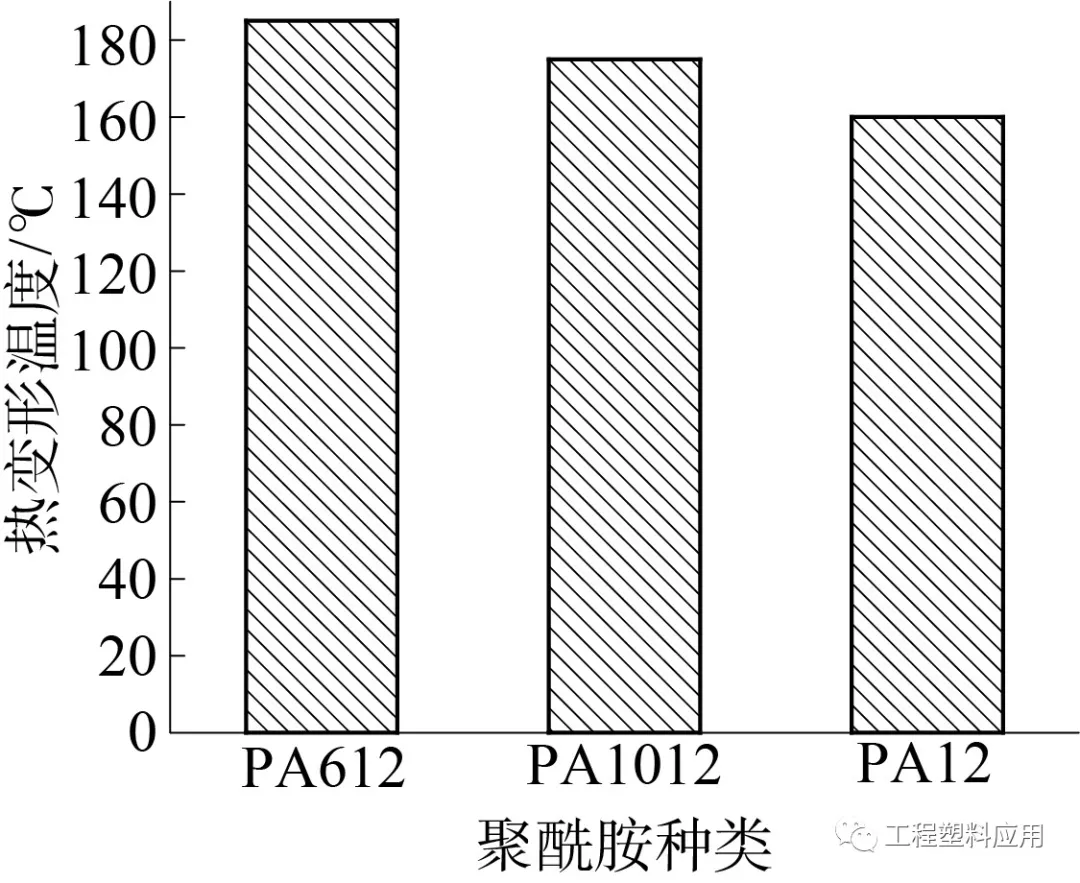

(2) Στην πρακτική εφαρμογή των τεχνικών πλαστικών, ειδικά για τα υλικά που περιβάλλουν τα εξαρτήματα του κινητήρα αυτοκινήτου, πρέπει να δοθεί ιδιαίτερη προσοχή στη θερμοκρασία θερμικής παραμόρφωσης των υλικών.Η παρακάτω εικόνα δείχνει τη θερμοκρασία θερμικής παραμόρφωσης των ενισχυμένων με GF διαφορετικών πολυαμιδίων μακράς αλυσίδας.Μπορεί να φανεί ότι η υψηλότερη θερμοκρασία θερμικής παραμόρφωσης του υλικού PA612/GF30 είναι 185℃, ακολουθεί το υλικό PA1012/GF30, το οποίο είναι 175℃, και το χειρότερο είναι το υλικό PA12/GF30, το οποίο είναι 160℃.Αυτό μπορεί να οφείλεται στο γεγονός ότι το PA612 έχει την υψηλότερη περιεκτικότητα σε αμίδιο και τη μεγαλύτερη κρυσταλλικότητα, με αποτέλεσμα την υψηλότερη θερμοκρασία θερμικής παραμόρφωσης.Η υψηλότερη θερμοκρασία θερμικής παραμόρφωσης σημαίνει ότι το υλικό μπορεί να χρησιμοποιηθεί σε εξαρτήματα αυτοκινήτων με υψηλότερες απαιτήσεις θερμοκρασίας.

Σύγκριση θερμοκρασίας θερμικής παραμόρφωσης

(3) Σύγκριση των πραγματικών προϊόντων χύτευσης με έγχυση

Λαμβάνοντας ως παράδειγμα ένα προϊόν χύτευσης με έγχυση ταχείας σύνδεσης ενός συστήματος εξάτμισης αυτοκινήτων, συγκρίθηκε η ποιότητα χύτευσης τριών ενισχυμένων με GF πολυαμιδικών υλικών μακράς αλυσίδας στη μηχανή χύτευσης με έγχυση. Η διαδικασία χύτευσης με έγχυση παρουσιάζεται στον Πίνακα 1. Ο Πίνακας 2 δείχνει την πραγματική σύγκριση της ποιότητας χύτευσης των διαφόρων προϊόντων χύτευσης με έγχυση από πολυαμίδιο μακράς αλυσίδας ενισχυμένο με GF. Όπως φαίνεται από τον Πίνακα 2, οι διαστάσεις των PA612/GF30 και PA1012/GF30 ανταποκρίνονται στις απαιτήσεις του πελάτη, αλλά η εμφάνιση του PA1012/GF30 είναι καλύτερη από εκείνη του PA612/GF30. Κάτω από τις ίδιες συνθήκες χύτευσης με έγχυση, η ρευστότητα του υλικού PA1012/GF30 είναι καλύτερη.Επιπλέον, τα προϊόντα που κατασκευάζονται από PA1012/GF30 είναι κατά 0,1 g βαρύτερα από τα προϊόντα που κατασκευάζονται από PA12/GF30, ενώ τα προϊόντα που κατασκευάζονται από PA612/GF30 είναι κατά 0,5 g βαρύτερα από τα προϊόντα που κατασκευάζονται από PA12/GF30.Κρίνοντας από την απόδοση του υλικού και την πραγματική κατάσταση χύτευσης με έγχυση, το PA1012/GF30 είναι το πιο οικονομικό υλικό για να αντικαταστήσει το PA12/GF30.