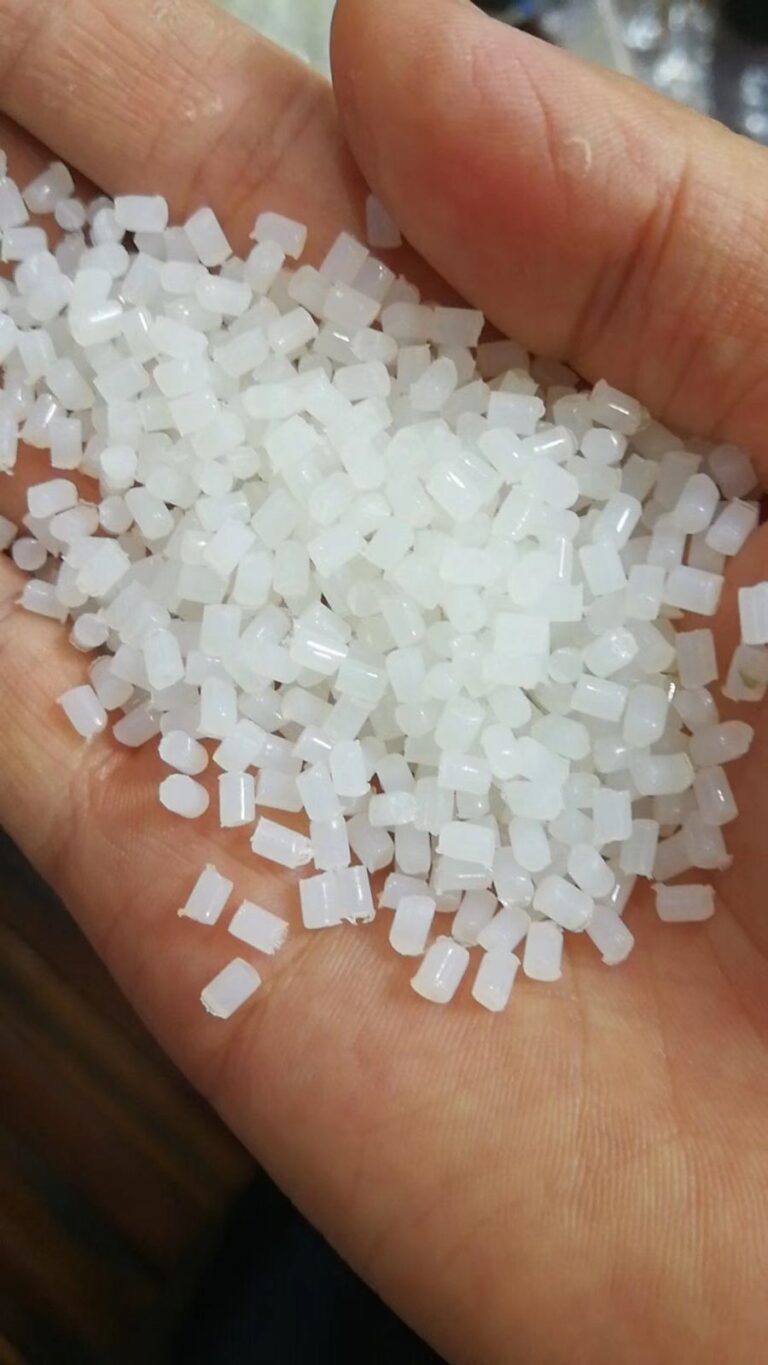

Poliamida 6 PA6: un material definido por su resistencia y durabilidad

Poliamida 6 PA6un polímero termoplástico versátil, es famoso por su excepcional fuerza, durabilidad y resistencia al desgaste. Estos atributos lo convierten en el material preferido en múltiples industrias, en particular la automovilística, la aeroespacial y la médica. En la industria de la automoción, la poliamida 6 PA6 se utiliza con frecuencia en la fabricación de componentes de motores, como bombas de combustible y válvulas, debido a su impresionante resistencia al calor y la corrosión. Además, desempeña un papel crucial en la producción de interiores de automóviles como cinturones de seguridad y sistemas de airbag, debido a su mayor resistencia a la tracción y flexibilidad.

Revolucionando el sector aeroespacial con PA6

El sector aeroespacial depende en gran medida de la poliamida 6 PA6 para diversos componentes, como interiores de aviones, sistemas de combustible y piezas de motores. La ligereza y la elevada relación resistencia-peso de la PA6 son vitales para reducir el peso total de los aviones, aumentar la eficiencia del combustible y disminuir las emisiones. Esta combinación de propiedades convierte a la PA6 en un material clave para el avance de la tecnología aeroespacial.

Avances en dispositivos médicos con PA6 biocompatible

En el ámbito médico, la poliamida 6 PA6 forma parte integral de la producción de dispositivos médicos, como instrumentos quirúrgicos, prótesis e implantes. Sus características de biocompatibilidad y no toxicidad garantizan que cumpla los estrictos requisitos de seguridad y eficacia para el cuidado de los pacientes. Además, la resistencia de la PA6 a las altas temperaturas y su capacidad para soportar procesos de esterilización la convierten en una opción ideal para equipos y dispositivos médicos que requieren una limpieza y desinfección frecuentes.

Mejora de los textiles con PA6 elástica y duradera

La industria textil utiliza ampliamente la PA6 por su excelente elasticidad y resistencia a la abrasión, lo que la hace ideal para la fabricación de prendas de vestir, calzado y diversos productos textiles. En la industria del deporte, el PA6 destaca en la creación de calzado y equipamiento deportivo, ya que proporciona un soporte y una durabilidad esenciales sin dejar de ser ligero y cómodo.

Optimización de soluciones de envasado con PA6

La PA6 también desempeña un papel importante en la industria del envasado, donde se utiliza para producir una amplia gama de materiales de envasado, incluidos envases para alimentos, botellas y tapones. Su capacidad para soportar altas temperaturas y resistir la humedad lo convierte en una opción óptima para el envasado de alimentos, garantizando la conservación de la frescura y la seguridad del contenido para el consumo.

El papel de la PA6 en el avance tecnológico moderno

En resumen, las propiedades versátiles y de alto rendimiento de la Poliamida 6 PA6 han consolidado su estatus como material crucial en diversas industrias. Sus aplicaciones en los sectores de la automoción, aeroespacial, médico, textil y del embalaje ponen de relieve su adaptabilidad a diversos requisitos, mejorando el rendimiento y la eficiencia de estas industrias. A medida que la investigación y el desarrollo continúan descubriendo nuevas aplicaciones para la PA6, este plástico de ingeniería sigue siendo fundamental para impulsar la innovación y el progreso tecnológicos modernos.

Preguntas frecuentes sobre la poliamida 6 PA6

La poliamida 6 PA6 es un plástico de ingeniería ampliamente utilizado y conocido por su versatilidad y propiedades superiores. Aquí encontrará algunas preguntas y respuestas frecuentes que le ayudarán a comprender mejor este material esencial.

1. ¿Qué es la poliamida 6 PA6?

Respuesta: La poliamida 6, comúnmente conocida como PA6, es un tipo de nailon producido mediante la polimerización de la caprolactama. Es conocida por su alta resistencia, durabilidad y resistencia al desgaste y a los productos químicos. Estas propiedades hacen que sea la opción preferida en varias industrias para fabricar componentes que deben soportar condiciones duras.

2. ¿En qué se diferencia la PA6 de otros tipos de poliamidas, como la PA66?

Respuesta: Mientras que tanto la PA6 como la PA66 son tipos de nailon, pero difieren en su estructura química y sus propiedades. La PA6 tiene un punto de fusión más bajo (aproximadamente 223 °C o 433 °F) que la PA66 (aproximadamente 255 °C o 491 °F). Esto hace que la PA6 sea más fácil de procesar, pero confiere a la PA66 una resistencia al calor ligeramente superior. La PA6 también absorbe más humedad que la PA66, lo que puede influir en sus propiedades mecánicas y estabilidad dimensional.

3. ¿Cuáles son las principales propiedades de la PA6?

Respuesta: La PA6 es conocida por varias propiedades clave:

- Alta resistencia mecánica: Soporta esfuerzos y tensiones importantes.

- Excelente durabilidad: Resistente a la abrasión y al desgaste, lo que la hace duradera.

- Resistencia química: Resistente a aceites, combustibles y productos químicos.

- Buena estabilidad térmica: Puede funcionar en una amplia gama de temperaturas.

- Gran resistencia a los impactos: Capaz de absorber y disipar la energía de los impactos.

- Estabilidad dimensional: Mantiene su forma y tamaño en diversas condiciones.

- Buen aislamiento eléctrico: Útil en aplicaciones eléctricas.

4. ¿Es reciclable la PA6?

Respuesta: Sí, la PA6 es reciclable. Puede fundirse y transformarse en nuevos productos, reduciendo los residuos y conservando los recursos. El reciclado de la PA6 puede realizarse mediante procesos mecánicos, en los que el material se tritura y funde, o procesos químicos, en los que se despolimeriza y vuelve a su monómero para su repolimerización.

5. ¿Cómo se comporta la poliamida 6 PA6 a altas temperaturas?

Respuesta: La poliamida 6 PA6 puede funcionar bien a altas temperaturas gracias a su buena estabilidad térmica. Tiene un punto de fusión de aproximadamente 223°C (433°F) y puede mantener sus propiedades mecánicas hasta unos 160°C (320°F) en uso continuo. Sin embargo, su rendimiento puede mejorarse con estabilizadores térmicos para aplicaciones que requieran una exposición prolongada a temperaturas más elevadas.

6. ¿Cuáles son las limitaciones de la poliamida 6 PA6?

Respuesta: Aunque la PA6 tiene muchas propiedades ventajosas, también presenta algunas limitaciones:

- Absorción de humedad: Puede absorber la humedad del ambiente, lo que puede afectar a sus propiedades mecánicas y a su estabilidad dimensional.

- Sensibilidad UV: La PA6 puede degradarse bajo una exposición prolongada a la luz ultravioleta (UV) a menos que se estabilice con inhibidores de UV.

- Menor resistencia al calor que otros nilones: La PA66, por ejemplo, tiene mejor resistencia al calor.

7. ¿Cómo gestiona la PA6 la exposición a sustancias químicas?

Respuesta: La PA6 es muy resistente a diversos productos químicos, como aceites, combustibles y muchos disolventes. Sin embargo, puede ser atacado por ácidos y bases fuertes. Su resistencia a los productos químicos lo hace adecuado para su uso en entornos químicos agresivos y en contacto con combustibles y aceites.

8. ¿Se puede procesar fácilmente la PA6?

Respuesta: Sí, la PA6 es relativamente fácil de procesar utilizando métodos comunes como el moldeo por inyección, la extrusión y el moldeo por soplado. Su punto de fusión más bajo en comparación con otros nylons facilita el procesamiento, por lo que es una opción popular para la fabricación de formas y componentes complejos.

9. ¿Cómo afecta la humedad a la PA6?

Respuesta: La PA6 puede absorber la humedad del aire, lo que puede provocar cambios en sus propiedades mecánicas y dimensiones. La absorción de humedad tiende a aumentar la flexibilidad y la tenacidad, pero puede reducir la rigidez y la resistencia. Esto debe tenerse en cuenta en aplicaciones en las que la estabilidad dimensional es crucial. Los grados especiales de PA6 o el uso de barreras contra la humedad pueden mitigar estos efectos.

10. ¿Existe algún problema medioambiental relacionado con el PA6?

Respuesta: Como muchos plásticos, el impacto medioambiental de la PA6 depende en gran medida de su producción, uso y eliminación. Aunque la PA6 es reciclable, su eliminación inadecuada puede contribuir a la contaminación por plásticos. Los avances en la tecnología del reciclado y el desarrollo de la PA6 de origen biológico pretenden reducir su huella medioambiental. Los esfuerzos para mejorar la sostenibilidad de la PA6 incluyen el aumento de su reciclabilidad y el uso de recursos renovables para su producción.

11. ¿Cuáles son los aditivos habituales utilizados con la PA6?

Respuesta: Para mejorar sus propiedades, la PA6 puede componerse con diversos aditivos, entre ellos:

- Fibras de vidrio: Mejora la fuerza y la rigidez.

- Rellenos minerales: Mejora la estabilidad dimensional y reduce los costes.

- Estabilizadores térmicos: Mejora el rendimiento a temperaturas más altas.

- Estabilizadores UV: Protege contra la degradación por la luz ultravioleta.

- Retardantes de llama: Reduce la inflamabilidad para un uso más seguro en entornos de alto riesgo.

12. ¿Cuáles son las perspectivas de futuro de la PA6?

Respuesta: El futuro de la PA6 se presenta prometedor gracias a la investigación y el desarrollo en curso para ampliar sus aplicaciones y mejorar sus propiedades. Innovaciones como la PA6 de origen biológico, la mejora de las técnicas de reciclado y las nuevas tecnologías de composición harán que la PA6 sea aún más versátil y sostenible, consolidando su papel en el avance de la tecnología y la industria modernas.

Para más detalles sobre la poliamida 6 PA6 o consultas sobre aplicaciones específicas, consulte a los expertos del sector o a los especialistas en materiales, que pueden ofrecerle asesoramiento personalizado en función de sus necesidades.