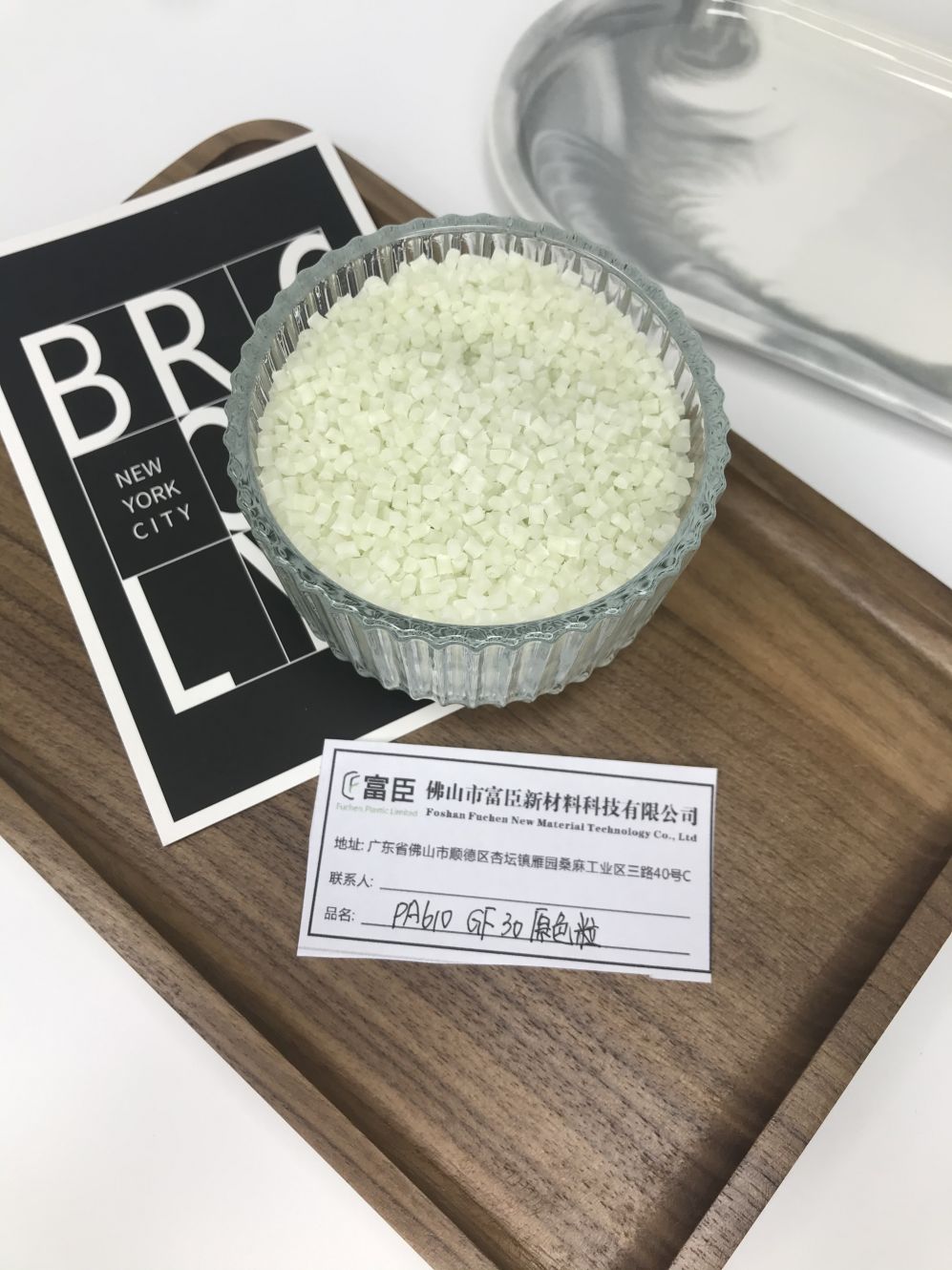

PA610 GF30 adalah plastik rekayasa yang kuat yang dibangun di atas fondasi Nylon 610, tetapi dengan peningkatan yang signifikan: penguatan serat kaca 30%. Mari kita pelajari apa artinya ini:

- Bahan Dasar: PA610jenis nilon yang dikenal karena kekuatan, elastisitas, dan ketahanan panasnya yang baik. Nilon ini juga menawarkan sifat kelistrikan yang menguntungkan dibandingkan dengan nilon lainnya.

- Penguatan Serat Kaca: "GF30" menandakan serat kaca 30% yang ditambahkan ke dalam plastik. Untaian kecil yang memperkuat ini secara signifikan meningkatkan kinerja material secara keseluruhan.

Manfaat utama dari PA610 GF30:

- Kekuatan yang Unggul: Dibandingkan dengan PA610 yang tidak terisi, kandungan serat kaca 30% secara dramatis meningkatkan kekuatan dan kekakuan material. Hal ini membuat PA610 GF30 ideal untuk aplikasi yang membutuhkan beban mekanis yang tinggi.

- Peningkatan Kekakuan: PA610 GF30 menunjukkan kelenturan dan kelengkungan yang jauh lebih sedikit dibandingkan dengan PA610 murni, sehingga menjadikannya pilihan yang tepat untuk komponen yang membutuhkan stabilitas dimensi.

- Sifat Kelistrikan yang Baik: PA610 sendiri memiliki sifat kelistrikan yang menguntungkan, dan penambahan serat kaca tidak secara signifikan menghalangi keunggulan ini.

Hal-hal yang Perlu Dipertimbangkan:

- Kerapuhan: Meskipun lebih kuat, PA610 GF30 bisa sedikit lebih rapuh daripada nilon yang tidak terisi. Ini berarti mungkin lebih rentan terhadap keretakan di bawah benturan tinggi.

- Berat: Kehadiran serat kaca meningkatkan berat keseluruhan bahan dibandingkan dengan PA610 murni.

- Kemampuan mesin: Pemesinan atau pengeboran PA610 GF30 mungkin sedikit lebih menantang karena adanya serat kaca.

Secara keseluruhan, PA610 GF30 adalah bahan yang berharga untuk aplikasi yang menuntut kekuatan, kekakuan, dan sifat kelistrikan yang baik. Ini biasanya digunakan dalam komponen otomotif, komponen elektronik, dan berbagai aplikasi industri.