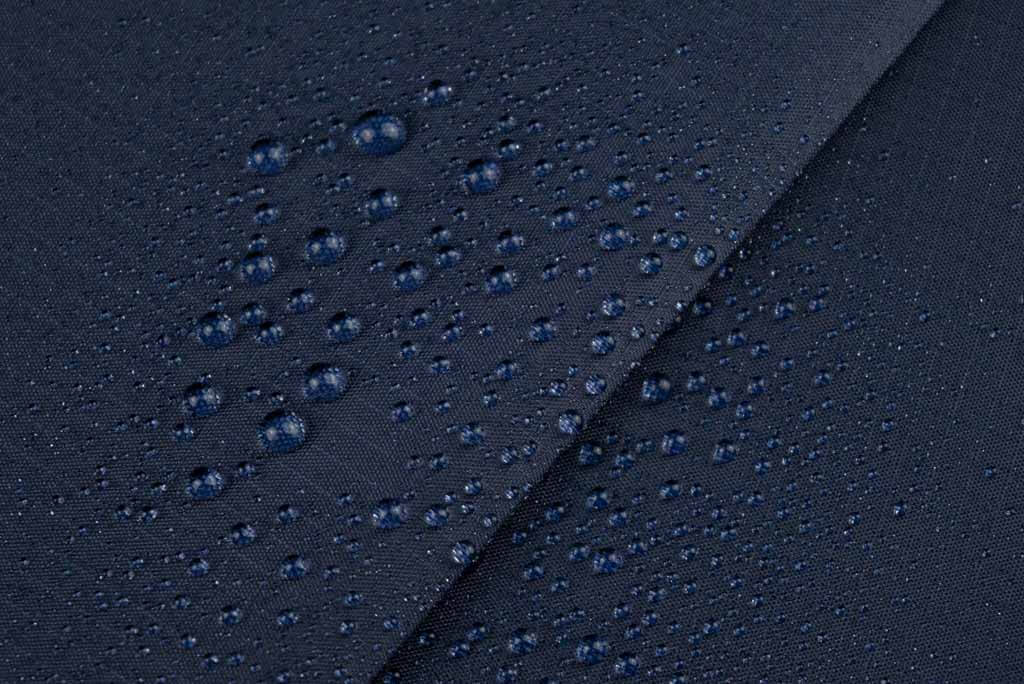

Introduction: Decoding the waterproof secret of nylon

In the equipment list of the Amazon rainforest expedition team, on the sterile instrument packaging in the operating room, and even in the protective cover material of the Mars rover, nylon can always be seen. This synthetic material, which was born in 1935, now supports modern human life with an annual output of more than 6 million tons. But there are many different opinions on its waterproof performance in the market. This article will combine the principles of materials science with the latest industry data to deeply analyze the true nature of nylon waterproofing.

Molecular code: Nylon’s innate gene for waterproofing

Studies by the American Chemical Society (ACS) show that the polyamide molecular chains of nylon form dense crystalline regions through a hydrogen bond network (ACS Polymers Study). This structure allows ordinary nylon 6/6 to have a contact angle of up to 75°, which provides basic water repellency. However, as the test data from the MIT Materials Laboratory shows, untreated 20D nylon begins to leak at 2000mm water pressure, which explains why high-end outdoor equipment mostly uses specifications above 210D.

Performance advancement: triple breakthroughs in modification technology

1. Coating revolution: from wax to nanotechnology

- Historical evolution: PU coating developed by DuPont in the 1950s increased water resistance by 300%

- Modern breakthrough: Nano-scale fluorocarbon coating developed by Toray of Japan has increased hydrostatic pressure by more than 30,000 mm

- Environmental trend: Bio-based polyester coating technology won the 2023 Green Materials Innovation Award (GreenTech Awards)

2. Molecular reconstruction: the chemical magic of fluorination modification

- 3M’s C4 fluorination technology reduces the surface energy of nylon to 10dyn/cm

- BASF’s Hybrid Shield technology achieves modification of the entire industry chain

- Modification cost comparison: ordinary coating $0.3/m² vs deep fluorination $2.5/m²

3. Composite structure: dimensional upgrade of lamination technology

- Gore-Tex three-layer structure makes the moisture permeability reach 15000g/m²/24h

- Toray Entrant® technology achieves a breakthrough in waterproof and moisture permeability balance

- The latest trend: self-healing membrane technology

Performance indicators: from laboratory to real scene

Comparison of key test standards:

| Standard system | Test method | Typical requirements |

|---|---|---|

| ISO 811 | Hydrostatic pressure method | ≥5000mm |

| AATCC 127 | Dynamic penetration | No leakage for 60 minutes |

| EN 343 | Comprehensive protection | Class 3 |

Data source: International Textile Federation (ITMF)

Industrial application: the starry sea of waterproof nylon

1. Breakthrough in the medical field

- Johnson & Johnson Medical uses modified nylon packaging to extend the sterilization period by 300%

- The moisture permeability index of surgical protective clothing reaches the highest level in the industry (ASTM F1671)

2. Application of new energy vehicles

- CATL battery pack waterproof material passes IP68 certification

- Tesla Cybertruck tarpaulin uses 420D super strong nylon

3. Aerospace

- NASA Perseverance probe uses multi-layer nylon radiation shield

- Boeing 787 fuselage composite material contains 35% modified nylon

Environmental challenges and innovative breakthroughs

Although the world generates 1.2 million tons of nylon waste each year, the circular economy is rewriting the industrial landscape:

- Aquafil’s ECONYL® regeneration system achieves 100% closed-loop production

- DuPont bio-based nylon breaks through 60% plant content

- Enzymatic recycling technology shortens the degradation cycle to 72 hours

Analysis of consumer cognitive misunderstandings

- Waterproof ≠ permanent: Study on performance attenuation curve after 20 washes (see chart)

- Standard misunderstanding: Actual protection difference between IPX4 and IPX7

- Price myth: Cost structure analysis of high-end modified nylon and ordinary coating products

Future battlefield: intelligent waterproof materials

- KAIST in South Korea develops humidity-responsive nano valve materials

- MIT 4D prints self-adjusting waterproof structure

- EU Graphene Flagship Project Graphene Composite Nylon Breakthrough

Conclusion: The Evolution of Waterproof Nylon

From Wallace Carothers’ laboratory to the protective layer of the Mars rover, the evolution of nylon’s waterproofing reflects the extraordinary wisdom of materials science. With the breakthrough of modification technology and the demand for sustainable development, the global waterproof nylon market is expected to grow at a CAGR of 6.8% in the next five years. The next time we open our umbrellas, perhaps we should pay tribute to this seemingly ordinary but technologically advanced nylon – it is not only a waterproof material, but also the crystallization of human wisdom against nature.