Nailono 66 naudojimas Įvadas

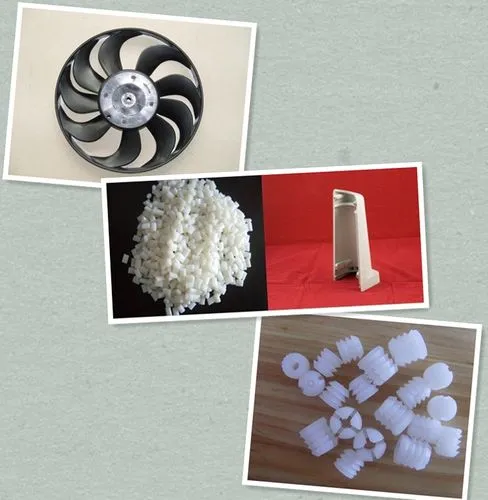

Nailonas 66sintetinis polimeras, žinomas dėl savo tvirtumo ir gebėjimo prisitaikyti, yra labai svarbus daugeliui šiuolaikinio gyvenimo aspektų. Iš pradžių sukurtas pramoninėms reikmėms, dabar dėl savo išskirtinių savybių, tokių kaip stiprumas, ilgaamžiškumas ir atsparumas dėvėjimuisi, jis įsiskverbė į daugelį pramonės šakų. Šiame straipsnyje nagrinėjamas nailono 66 panaudojimas įvairiose srityse ir parodoma, kaip jis tapo neatsiejama mūsų kasdienybės ir pramonės procesų dalimi.

Nailono 66 naudojimas automobilių pramonėje

Automobilių sektoriuje nailono 66 tvirtos savybės yra būtinos. Šis polimeras plačiai naudojamas kuriant įvairias automobilių dalis, pavyzdžiui, variklio komponentus, transmisijos sistemas ir pakabos sistemas. Jo tvirtumas užtikrina, kad šios dalys atlaikytų didelę apkrovą, o ilgaamžiškumas sumažina keitimo ir techninės priežiūros dažnumą, galiausiai padidindamas automobilio ilgaamžiškumą ir eksploatacines savybes.

Nailono 66 naudojimas Tekstilė ir audiniai

Nailono 66 indėlis į tekstilės pramonę yra didelis. Dėl didelio atsparumo tempimui ir elastingumo jis idealiai tinka įvairiems drabužiams, įskaitant aktyviąją aprangą, viršutinius drabužius ir maudymosi kostiumėlius, gaminti. Lengvas nailono 66 audinių svoris užtikrina patogumą ir lengvą priežiūrą, o atsparumas dilimui užtikrina, kad šie drabužiai laikui bėgant išliktų funkcionalūs ir išlaikytų savo išvaizdą net ir reguliariai juos naudojant.

Nailono 66 naudojimas Statybos pramonė

Statybose nailonas 66 yra pageidaujama medžiaga tvirtinimo detalėms, pavyzdžiui, varžtams, varžtams ir veržlėms, gaminti. Dėl išskirtinio tvirtumo ir atsparumo kasdieniam dėvėjimuisi bei cheminių medžiagų poveikiui ji puikiai tinka šioms reikmėms. Iš nailono 66 pagamintos tvirtinimo detalės patikimai veikia sudėtingoje aplinkoje, užtikrina ilgalaikį patvarumą ir išlaiko vientisumą nuolat naudojant.

Nailono 66 naudojimas Sporto įranga

Nailonas 66 taip pat yra labai svarbi medžiaga gaminant sporto įrangą, įskaitant slidinėjimo raiščius, ledo ritulio lazdas ir golfo lazdų galvutes. Polimero tvirtumas ir ilgaamžiškumas leidžia jam atlaikyti stiprius smūgius ir spaudimą, būdingus didelio poveikio sporto šakoms. Jo atsparumas dilimui užtikrina, kad šie gaminiai išliktų veiksmingi ir estetiškai patrauklūs, nepaisant griežto naudojimo.

Nailono 66 naudojimas Medicinos prietaisai

Medicinos srityje nailonas 66 vertinamas dėl savo tvirtumo ir biologinio suderinamumo. Jis dažniausiai naudojamas chirurginiams siūlams ir įvairiems medicinos prietaisams, kuriems būtinas tiesioginis sąlytis su žmogaus kūnu. Nailono 66 atsparumas irimui užtikrina, kad šie prietaisai laikui bėgant išliktų saugūs ir veiksmingi, patikimai veikiantys svarbiausiose srityse.

Nailono 66 naudojimas Vartojimo produktai

Nailonas 66 naudojamas daugelyje kasdienio vartojimo gaminių, įskaitant dantų šepetėlius, plaukų šepečius ir muzikos instrumentus. Dėl savo tvirtumo šie gaminiai yra atsparūs dažnam naudojimui, o dėl atsparumo nusidėvėjimui jie išlaiko savo funkcionalumą ir išvaizdą. Dėl šių savybių nailonas 66 yra ideali medžiaga gaminiams, skirtiems kasdieniam naudojimui.

Nailono 66 naudojimas Išvada

Dėl nailono 66 universalumo ir puikių savybių jis yra labai svarbi medžiaga įvairiose pramonės šakose. Nailono 66 panaudojimo sritys yra labai plačios ir svarbios - nuo automobilių komponentų našumo ir patvarumo didinimo iki tekstilės gaminių patogumo ir elastingumo užtikrinimo. Jo vaidmuo medicinos prietaisuose ir kasdienio vartojimo produktuose rodo jo platų poveikį gerinant kokybę ir funkcionalumą mūsų kasdieniame gyvenime. Technologijoms ir pramonei toliau vystantis, nailonas 66 išlieka kertinė medžiaga, padedanti ir tobulinanti daugybę taikymo sričių.

DUK santrauka: Nailono 66 universalumas

1. Kas yra nailonas 66 ir kodėl jis svarbus?

Nailonas 66 yra sintetinis polimeras, pasižymintis dideliu tvirtumu, ilgaamžiškumu ir atsparumu dilimui. Dėl šių savybių jis yra labai svarbus įvairiose pramonės šakose, įskaitant automobilių, tekstilės, statybos, sporto įrangos, medicinos prietaisų ir plataus vartojimo gaminių pramonę. Jo universalumas ir tvirtumas leidžia pagerinti daugelio kasdienių daiktų kokybę, našumą ir ilgaamžiškumą.

2. Kaip nailonas 66 naudojamas automobilių pramonėje?

Automobilių sektoriuje nailonas 66 naudojamas svarbiems komponentams, pavyzdžiui, variklio dalims, transmisijos sistemoms ir pakabos sistemoms, gaminti. Jo stiprumas ir patvarumas padeda šioms dalims atlaikyti didelę apkrovą ir sumažinti dažnos techninės priežiūros ir keitimo poreikį, todėl pagerėja transporto priemonės eksploatacinės savybės ir ilgaamžiškumas.

3. Kokie yra nailono 66 privalumai tekstilėje ir audiniuose?

Nailonas 66 vertinamas tekstilės pramonėje dėl didelio tempimo stiprumo ir elastingumo. Dėl šių savybių jis idealiai tinka įvairiems drabužiams, įskaitant aktyviąją aprangą, viršutinius drabužius ir maudymosi kostiumėlius, gaminti. Jo lengvumas užtikrina patogumą ir lengvą priežiūrą, o atsparumas trinčiai ilgainiui išlaiko drabužių išvaizdą ir funkcionalumą.

4. Kodėl nailonas 66 naudojamas statybinėse sąvaržose?

Dėl išskirtinio tvirtumo ir ilgaamžiškumo nailonas 66 dažniausiai naudojamas statybose tvirtinimo detalėms, pavyzdžiui, varžtams, varžtams ir veržlėms, gaminti. Jis gali atlaikyti kasdienio naudojimo sunkumus ir atšiaurios aplinkos poveikį neprarasdamas eksploatacinių savybių. Atsparumas korozijai ir cheminėms medžiagoms taip pat užtikrina, kad šios tvirtinimo detalės išliktų veiksmingos sudėtingomis sąlygomis.

5. Kuo nailonas 66 naudingas sporto įrangai?

Nailonas 66 idealiai tinka tokiai sporto įrangai kaip slidinėjimo raiščiai, ledo ritulio lazdos ir golfo lazdų galvutės, nes gali atlaikyti didelį smūgį ir nusidėvėjimą. Jo tvirtumas ir atsparumas dilimui užtikrina, kad šie daiktai išliktų funkcionalūs ir laikui bėgant išsaugotų savo eksploatacines savybes bei išvaizdą net ir intensyviai naudojant.

6. Kokiais būdais Nailonas 66 naudojamas medicinos srityje?

Medicinos pramonėje nailonas 66 dėl savo tvirtumo ir biologinio suderinamumo naudojamas chirurginiams siūlams ir įvairiems medicinos prietaisams gaminti. Dėl šių savybių jis saugus tiesioginiam sąlyčiui su žmogaus kūnu ir užtikrina, kad prietaisai ilgai išliktų funkcionalūs ir veiksmingi, o jų kokybė nesuprastėtų.

7. Kokie kasdienio vartojimo produktai gaminami iš nailono 66?

Nailonas 66 naudojamas įvairiuose kasdienio vartojimo gaminiuose, įskaitant dantų šepetėlius, plaukų šepetėlius ir muzikos instrumentus. Dėl savo patvarumo ir atsparumo nusidėvėjimui jis yra puiki medžiaga gaminiams, kuriuos reikia nuolat naudoti, nes užtikrina, kad jie išliks funkcionalūs ir išvaizdūs, nepaisant dažno naudojimo.

8. Kodėl nailonas 66 laikomas universalia medžiaga?

Nailono 66 stiprumo, ilgaamžiškumo ir atsparumo dilimui derinys leidžia jį naudoti įvairiose pramonės šakose. Nepriklausomai nuo to, ar jis naudojamas didelės apkrovos reikalaujančiose automobilių detalėse, patogiuose ir elastinguose drabužiuose, patikimose statybinėse tvirtinimo detalėse, patvarioje sporto įrangoje, saugiuose medicinos prietaisuose ar kasdienio vartojimo prekėse, nailonas 66 nuolat gerina gaminių kokybę ir ilgaamžiškumą.