Inleiding van Nylon Polymeer Thermisch Geleidingsvermogen

Thermische geleidbaarheid is een fundamentele eigenschap die bepaalt hoe materialen warmte beheren en overdragen. In een tijdperk waarin thermisch beheer van cruciaal belang is in verschillende industrieën, kan inzicht in de nuances van de thermische geleidbaarheid van nylon polymeer nieuwe mogelijkheden ontsluiten. Dit artikel verdiept zich in de fijne kneepjes van de thermische eigenschappen van nylon polymeer en belicht de toepassingen, verbeteringen en innovatieve stappen die het onmisbaar maken in de moderne technologie.

Wat is Nylon Polymeer?

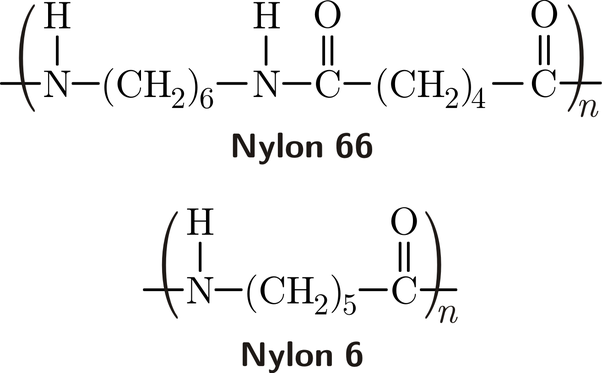

Een korte geschiedenis en unieke eigenschappen van nylon polymeer

Nylon polymeer, een baanbrekende uitvinding van Wallace Carothers in de jaren 1930, markeerde het begin van synthetische vezels. Door de unieke samenstelling van polyamiden is het niet alleen sterk en elastisch, maar ook zeer goed bestand tegen slijtage, chemicaliën en temperatuurschommelingen. Door deze eigenschappen is nylon uitgegroeid tot een veelzijdig materiaal voor zowel alledaagse als industriële toepassingen.

Uitgebreide toepassingen van nylon polymeer in verschillende industrieën

Het aanpassingsvermogen van nylon polymeer breidt het gebruik ervan uit over verschillende sectoren. In de auto-industrie vormt het de ruggengraat van onderdelen zoals motorkappen en luchtinlaatspruitstukken. In textiel wordt nylon geroemd om zijn duurzaamheid en lichte gewicht. De elektronica-industrie gebruikt nylon voor isolatoren en connectoren, dankzij zijn thermische weerstand en elektrisch isolerende eigenschappen. Het is ook prominent aanwezig in consumptiegoederen, sportuitrusting en medische apparatuur, wat zijn veelzijdige nut aantoont.

Wat is Nylon Polymeer Thermische geleidbaarheid?

Belangrijke factoren die het warmtegeleidingsvermogen beïnvloeden

Verschillende factoren bepalen de thermische geleidbaarheid van nylon polymeer, waaronder de moleculaire structuur, de mate van kristalliniteit en de aanwezigheid van additieven. Een hogere kristalliniteit verbetert doorgaans het warmtegeleidingsvermogen, omdat de geordende moleculaire rangschikking een efficiënte warmteoverdracht vergemakkelijkt. Omgekeerd belemmeren amorfe gebieden de warmtestroom. Verwerkingsomstandigheden, zoals koelsnelheden en giettechnieken, hebben een verdere invloed op de thermische eigenschappen van nylon.

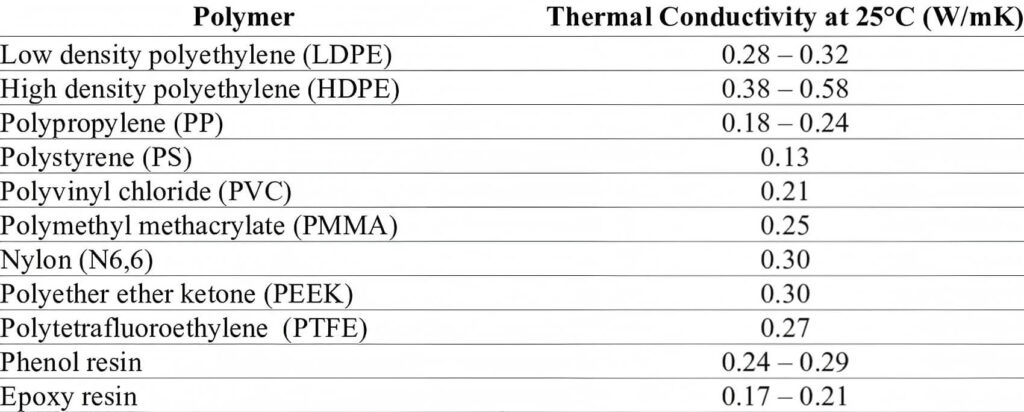

Vergelijkende analyse: Nylon Polymeer Versus Andere Materialen

Op het gebied van warmtegeleiding neemt het nylon polymeer een unieke positie in. Terwijl metalen als koper en aluminium een hoog warmtegeleidingsvermogen van 200-400 W/mK hebben, ligt dat bij nylon tussen 0,2-0,4 W/mK. Dit lagere geleidingsvermogen maakt nylon tot een uitstekende isolator. In vergelijking met andere polymeren vertoont nylon een superieur thermisch beheer, waardoor het de voorkeur geniet in toepassingen waar een gematigde hittebestendigheid van cruciaal belang is.

Innovaties in het verbeteren van thermische geleidbaarheid

Hoogfrequente aanpassingen: Een spelwisselaar

Vooruitgang in de polymeerwetenschap heeft geleid tot hoogfrequente modificaties om de thermische geleidbaarheid van nylon te verbeteren. Deze wijzigingen bestaan uit het veranderen van de moleculaire structuur door de toevoeging van warmtegeleidende vulstoffen of de strategische oriëntatie van polymeerketens tijdens de verwerking. Het resultaat is een materiaal dat de kloof tussen thermische isolatie en geleidbaarheid overbrugt.

Casestudies van effectieve aanpassingen

Voorbeelden van deze modificaties zijn de toevoeging van op koolstof gebaseerde vulstoffen zoals grafeen en koolstofnanobuizen, die geleidende paden creëren binnen de polymeermatrix. Boornitride en aluminiumoxide worden ook gebruikt om de thermische geleidbaarheid te verbeteren zonder de mechanische eigenschappen van nylon aan te tasten. Dergelijke innovaties hebben de weg geëffend voor de toepassing van nylon in warmte-intensieve omgevingen, zoals elektronische behuizingen en auto-onderdelen.

Praktische implicaties van verbeterde warmtegeleiding

Structurele invloed op thermische dynamica

De intrinsieke structuur van nylon polymeer heeft een aanzienlijke invloed op het thermische gedrag. Kristallijne gebieden, gekenmerkt door dicht opeengepakte polymeerketens, bieden minder weerstand tegen warmtestroming. Deze structurele eigenschap wordt gebruikt in hoogwaardige toepassingen waar een efficiënt thermisch beheer cruciaal is.

De rol van additieven in thermische verbetering

Additieven spelen een cruciale rol in het verhogen van de thermische geleidbaarheid van nylon. Door materialen zoals metaaldeeltjes of keramische vulstoffen te integreren, kunnen fabrikanten de thermische eigenschappen van nylon aanpassen aan specifieke toepassingsbehoeften. Deze aanpassing vergroot de veelzijdigheid van het polymeer, waardoor het doeltreffend kan functioneren in omgevingen die een nauwkeurige thermische controle vereisen.

Uitbreiding van toepassingen: Van elektronica tot dagelijks gebruik

De verbeterde thermische geleidbaarheid van nylon polymeer opent nieuwe perspectieven in verschillende industrieën. In de elektronica helpt het bij de warmteafvoer van componenten zoals LED-behuizingen en batterijbehuizingen. In de automobielsector verbetert het de prestaties van onderdelen onder de motorkap die aan hoge temperaturen worden blootgesteld. Zelfs in consumentengoederen wordt thermisch versterkt nylon gebruikt in keukentoestellen en sportuitrusting, voor betere prestaties en een langere levensduur.

Het aanpakken van Gemeenschappelijke Vragen over de Thermische Eigenschappen van het Nylon Polymeer

Structurele invloed op warmtegeleiding

De relatie tussen de moleculaire structuur van nylon en zijn thermische geleidbaarheid is een onderwerp van grote interesse. Hogere kristalliniteitsniveaus resulteren in een efficiëntere warmteoverdracht, waardoor dit een kritieke factor is bij het ontwerp en de toepassing van op nylon gebaseerde producten.

Potentieel voor thermische verbetering door additieven

De toevoeging van additieven is een beproefde strategie om de thermische geleidbaarheid van nylon te verbeteren. Door de juiste vulstoffen te kiezen, kunnen fabrikanten nylon composieten maken die voldoen aan de veeleisende thermische vereisten van moderne toepassingen, zonder andere wenselijke eigenschappen op te offeren.

Toepassingen in de echte wereld van Nylon met hoog warmtegeleidingsvermogen

Nylon met een hoge thermische geleidbaarheid vindt steeds meer zijn plaats in toepassingen die een superieur warmtebeheer vereisen. Van elektronische apparaten die efficiënt moeten worden gekoeld tot auto-onderdelen die extreme temperaturen verdragen, de praktische voordelen van thermisch versterkt nylon zijn enorm en gevarieerd.

Conclusie

De reis van nylon polymeer van een synthetische vezel naar een hoogwaardig materiaal is een voorbeeld van de evolutie van de materiaalwetenschap. De thermische geleidbaarheid, ooit een beperkende factor, is aanzienlijk verbeterd door innovatieve modificaties en het strategische gebruik van additieven. Dit heeft het toepassingsspectrum verbreed, waardoor het van onschatbare waarde is geworden in industrieën variërend van elektronica tot de auto-industrie. Naarmate de technologie zich blijft ontwikkelen, zal de rol van nylon polymeer in thermisch beheer alleen maar toenemen, waardoor zijn status als hoeksteenmateriaal in de moderne techniek wordt verstevigd.