NYLON 612 FEATURE

✔ High Mechanical Strength

✔ Good Chemical Resistance

✔ Excellent Abrasion Resistance

✔ Low Moisture Absorption

✔ Good Electrical Insulator

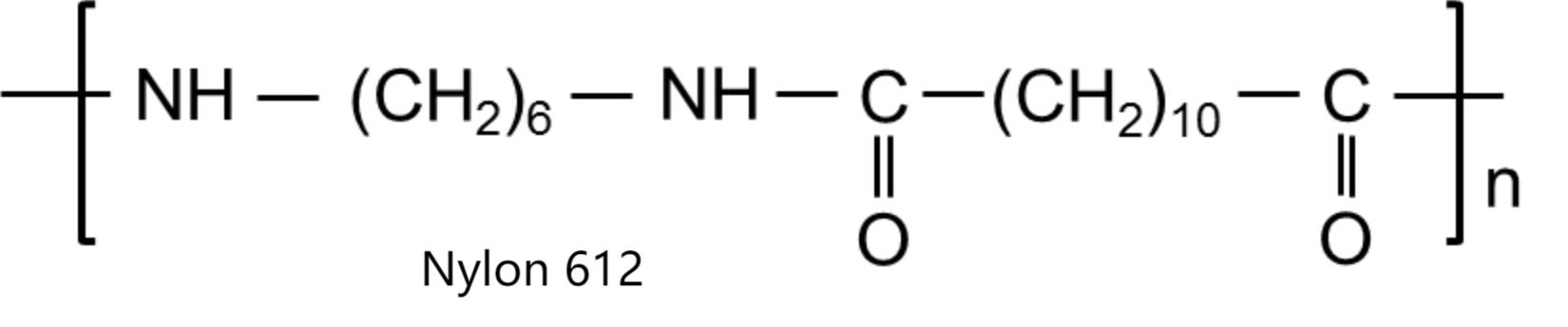

Nylon 612, also known as Polyamide 612 (PA 612), is a versatile engineering plastic prized for its exceptional blend of properties. It belongs to the polyamide family, sharing similarities with other nylons, but with some key advantages.

As a semi-crystalline polymer, Nylon 612 boasts impressive mechanical strength, stiffness, and excellent resistance to abrasion. This makes it a go-to material for parts that endure wear and tear, like gears, bearings, and components under friction.

But Nylon 612 goes beyond just mechanical toughness. It showcases superior heat resistance compared to other nylons, allowing it to perform well in high-temperature environments like under-the-hood automotive parts or industrial machinery. Additionally, it offers good electrical insulation, making it suitable for electrical components.

One of its strengths is also low moisture absorption, which helps parts made from Nylon 612 maintain their shape and size even in humid environments. However, keep in mind that Nylon 612 can degrade under UV light exposure. If used outdoors, additives or coatings might be needed to enhance UV resistance.

PA612 Black Resin offers the same strength and wear resistance as natural, but with a black pigment for products needing a darker color.

PA612 GF25 is a type of PA612 nylon reinforced with 25% glass fiber, making it even stronger and stiffer than natural PA612.

PA612 GF30 is a PA612 nylon with 30% glass fibers added for exceptional strength, stiffness, and dimensional stability.

Nylon 612, also called Polyamide 612 (PA 612), is a strong and versatile plastic known for its excellent performance in several key areas.

The key difference is its lower moisture absorption, making it more dimensionally stable in humid environments.