Nylons Plastic: Versatile and Strong Engineering Plastics

Nylon plastic, also known as polyamide (PA) or by the trade name Nylatron, is a semi-crystalline thermoplastic valued for its combination of properties. Nylon resin offer low density and high thermal stability, making them ideal for demanding applications.

Nylatrion GSM, a specific type of nylon resin, demonstrates this versatility. It incorporates molybdenum disulfide (MoS₂) for enhanced load-bearing capabilities while maintaining the impact resistance inherent to nylon. This combination makes Nylatron GSM a popular choice for gears, sprockets, and custom parts.

Polyamide designations like PA 6, PA 66, PA11, PA 12, and PA 46 reflect the underlying molecular structure, resulting in a range of properties. PA 66, for example, is known for its hardness and toughness, while PA 12 offers greater flexibility. Melting points for different nylon polymers typically fall between 220 °C and 260 °C.

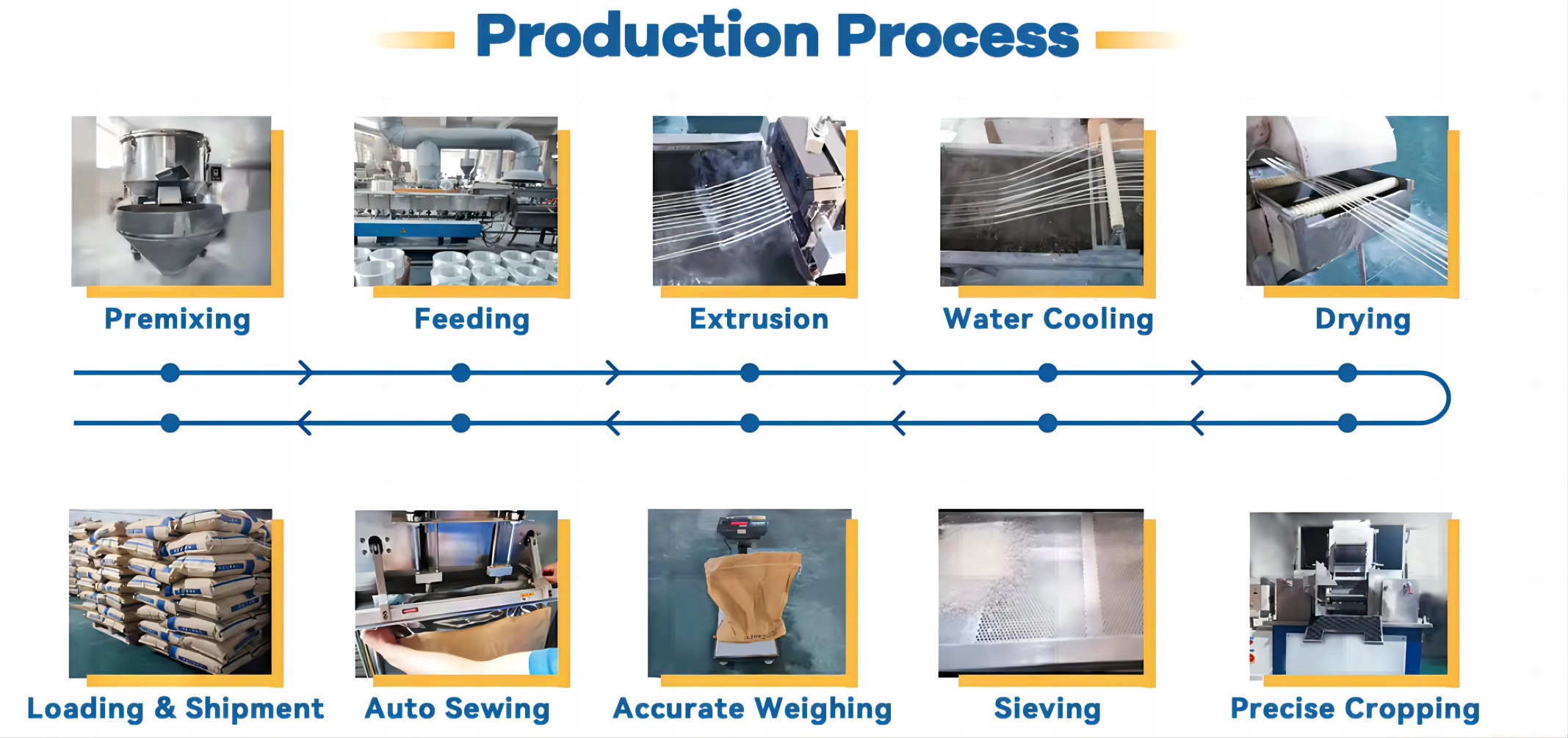

PA 6 and PA 66 are the most commonly used nylon types. They can be processed using various techniques, including extrusion, injection molding, and casting, making them highly versatile.

Due to this ease of processing, numerous polyamide modifications exist. Adding reinforcements like glass or carbon fibers significantly boosts strength and stiffness in specific grades, creating materials like glass-filled nylon and carbon-filled nylon.

Polyamides also boast excellent chemical resistance, particularly against oils. This, combined with their high strength, toughness, and low weight, makes them a compelling alternative to metals. From automotive parts and industrial valves to railway sleeper insulation and other technical applications, PA polymers find widespread use. For food contact applications, special food-grade nylons are available.

One key consideration for nylon design is its water absorption. Different types of polyamides absorb varying amounts of moisture. This water uptake can cause dimensional changes and affect mechanical properties, so it’s important to factor this into the design process for nylon components.