PA6 Glass Fiber, takes regular nylon plastic to the next level. By incorporating glass fibers into the nylon (PA6) matrix, this composite material boasts significant improvements in key performance areas. Compared to its unreinforced counterpart, PA6 Glass Fiber offers:

- Enhanced Strength: The addition of glass fibers significantly increases the material’s tensile strength, making it resistant to higher loads and forces without breaking.

- Improved Stiffness: PA6 Glass Fiber exhibits greater rigidity, making it ideal for applications requiring dimensional stability and resistance to bending or warping.

- Elevated Heat Resistance: The glass fibers enhance the material’s ability to withstand higher temperatures before deformation, expanding its potential for use in hot environments.

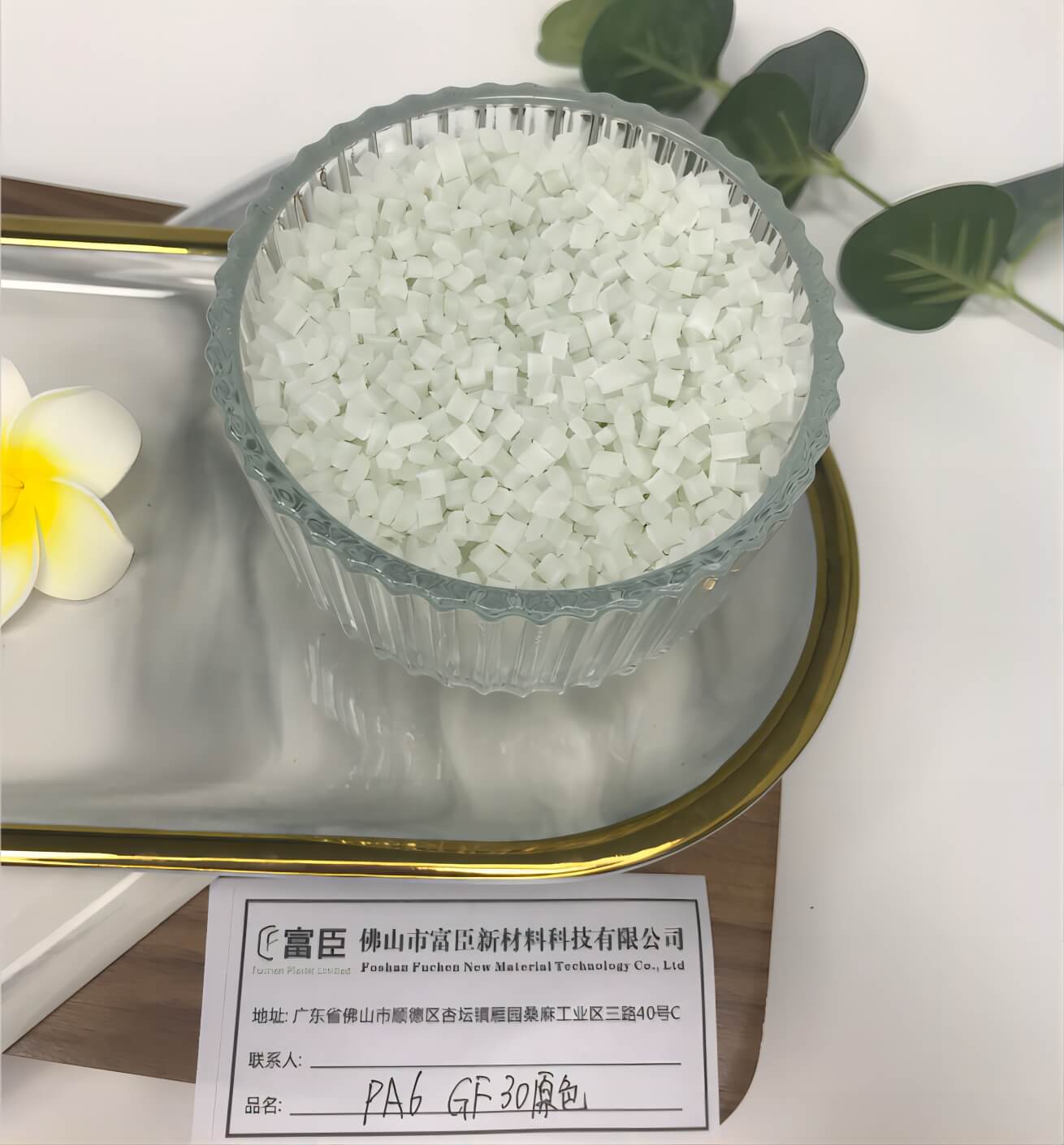

PA6 Glass Fiber is often designated with the percentage of glass fiber content following “PA6 GF.” For example, “PA6 GF30” indicates a material with 30% glass fibers by weight. This specific variant, PA6 GF30, strikes a good balance between enhanced properties and affordability, making it a popular choice for various applications.

Applications of PA6 Glass Fiber:

The improved properties of PA6 Glass Fiber open doors for its use in a broad spectrum of industries. Here are some specific examples:

- Electrical Components: Due to its enhanced strength and good electrical insulation properties, PA6 Glass Fiber finds application in electrical components like PA6-gf30 switches. These switches can handle higher loads and operate reliably in demanding environments.

- Mechanical Parts: The material’s strength and stiffness make it suitable for various mechanical parts. Take PA6-gf30 filters for instance. These filters can withstand the pressure of fluids while maintaining their shape, ensuring efficient filtration.

- Automotive Industry: PA6 Glass Fiber finds use in automotive components that require both strength and lightweight properties. Examples include engine parts, gears, and structural components.

- Consumer Goods: Due to its good balance of properties and processibility, PA6 Glass Fiber can be found in various consumer goods like appliance housings, tool handles, and sporting goods.

Beyond these examples, PA6 Glass Fiber’s versatility extends to other industries such as construction, aerospace, and medical devices.

PA6 Glass Fiber offers a compelling combination of enhanced strength, stiffness, and heat resistance compared to regular nylon. With various grades like PA6 GF30 available, this material caters to a wide range of demanding applications across diverse industries.