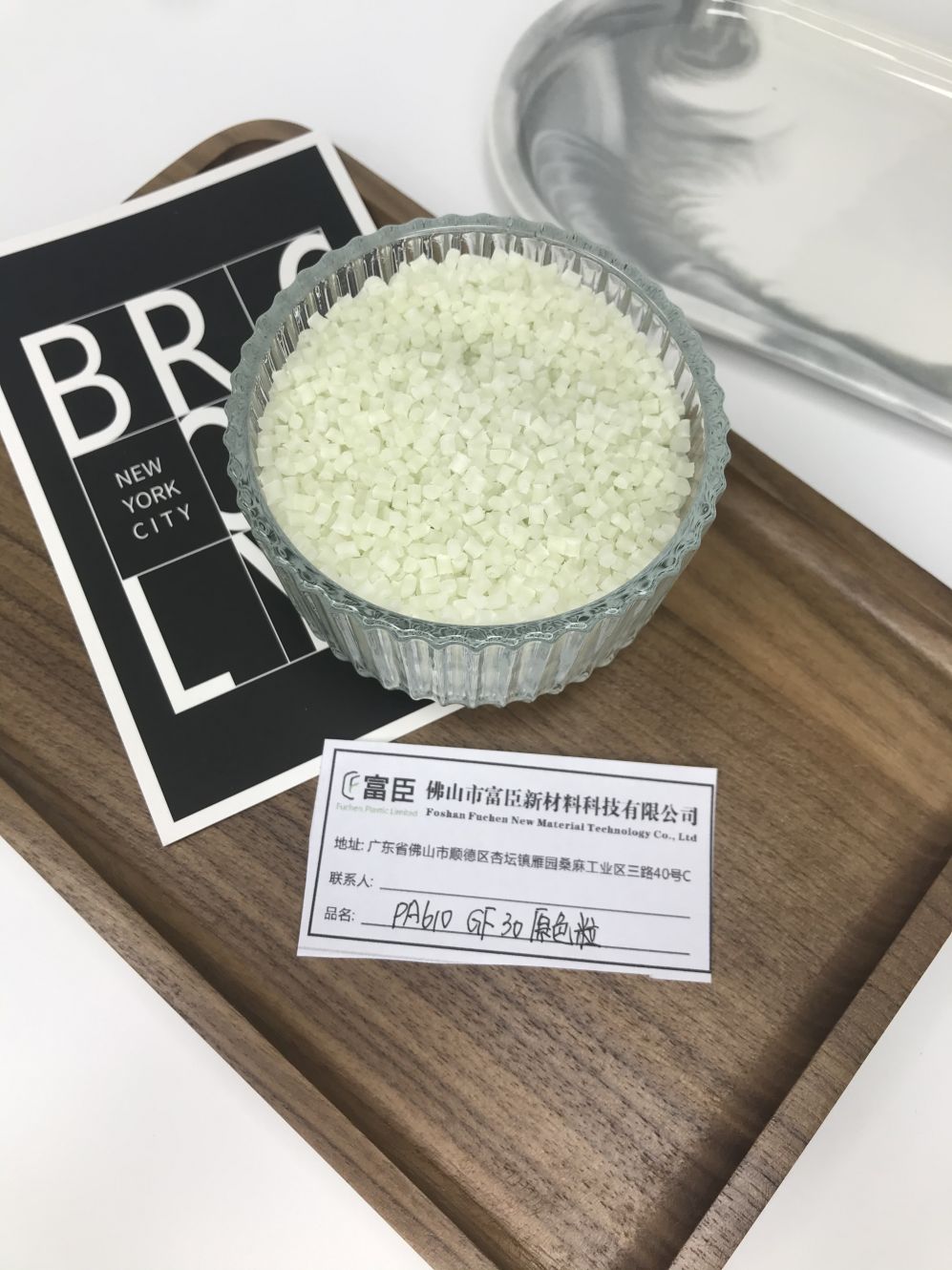

PA610 GF30 is a robust engineering plastic built on a foundation of Nylon 610, but with a significant upgrade: 30% glass fiber reinforcement. Let’s delve into what this means:

- Base Material: PA610, a type of nylon known for its inherent strength, elasticity, and good heat resistance. It also offers favorable electrical properties compared to other nylons.

- Glass Fiber Reinforcement: The “GF30” signifies 30% glass fibers are added to the plastic. These tiny, reinforcing strands significantly enhance the material’s overall performance.

Key benefits of PA610 GF30:

- Superior Strength: Compared to unfilled PA610, the 30% glass fiber content dramatically improves the material’s tensile strength and rigidity. This makes PA610 GF30 ideal for applications requiring high mechanical loads.

- Increased Stiffness: PA610 GF30 exhibits significantly less flex and bend compared to pure PA610, making it a great choice for components needing dimensional stability.

- Good Electrical Properties: PA610 itself boasts favorable electrical properties, and the addition of glass fibers doesn’t significantly hinder this advantage.

Things to Consider:

- Brittleness: While stronger, PA610 GF30 can be slightly more brittle than unfilled nylon. This means it may be more susceptible to cracking under high impact.

- Weight: The presence of glass fibers increases the overall weight of the material compared to pure PA610.

- Machinability: Machining or drilling PA610 GF30 might be slightly more challenging due to the presence of glass fibers.

Overall, PA610 GF30 is a valuable material for demanding applications where superior strength, stiffness, and good electrical properties are crucial. It’s commonly used in automotive parts, electronic components, and various industrial applications.