PA66 Glass Fiber

PA66 glass fiber is a type of nylon 66 plastic reinforced with glass fibers. This reinforcement significantly enhances its strength, stiffness, and dimensional stability compared to standard PA66. It’s commonly used in demanding applications requiring high mechanical performance.

The availble types:

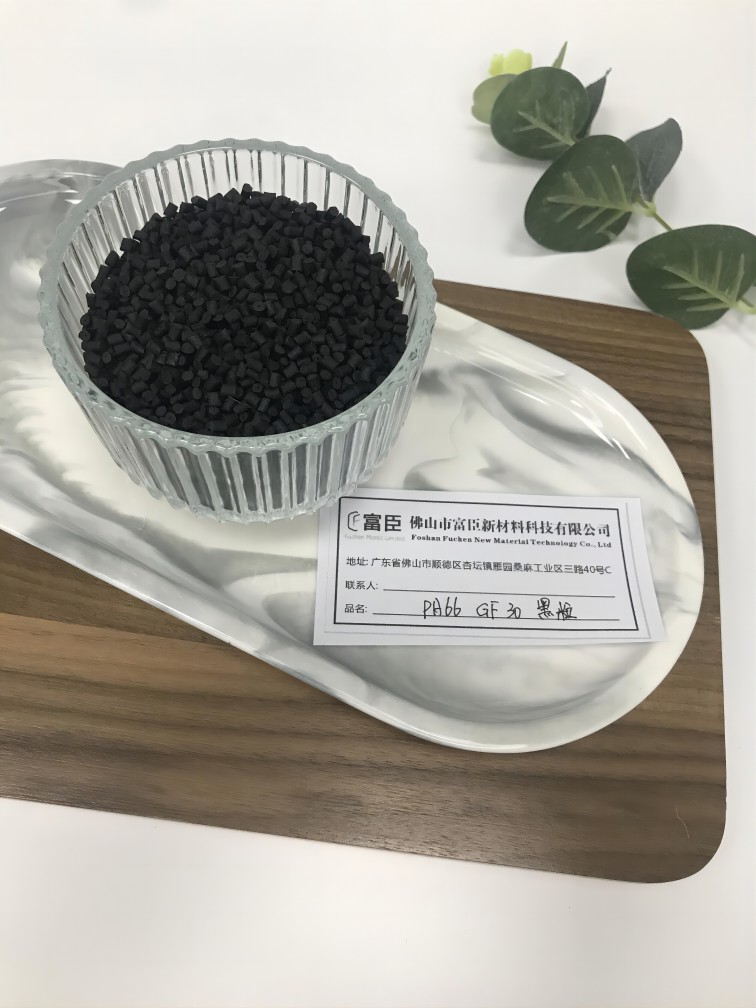

- PA66 GF30 (Natural/Black)

- PA66 GF25 (Natural/Black)

- PA66 GF20 (Natural/Black)