Abstract

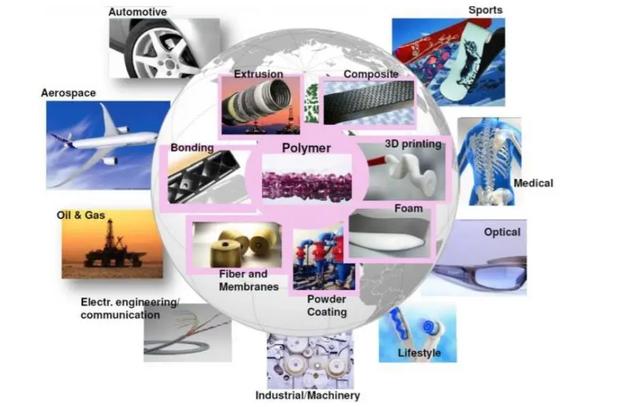

From lightweight and wear-resistant outdoor jackets to sturdy and reliable car engine parts, from insulated and safe electrical cables to aircraft structures that soar into the sky, nylon, a synthetic fiber born in the laboratory, has quietly penetrated into every corner of human production and life with its unique comprehensive properties. This article will deeply analyze the wide application of nylon in eight key areas and reveal its irreplaceable position as the cornerstone of modern materials.

1. Fashion and functional clothing: comfortable and durable daily guardian

Nylon fiber has completely revolutionized the modern clothing industry with its lightness, softness, high strength and excellent wrinkle resistance. Its excellent moisture absorption and quick-drying properties make it an ideal choice for sportswear and summer clothing (such as the quick-drying technology widely used by well-known sports brands). Compared with natural fibers, nylon is more wear-resistant and less prone to deformation, greatly extending the service life of jackets, trousers and even underwear. Patagonia, an internationally renowned outdoor brand, emphasizes the advantages of nylon blended fabrics in durability and environmentally friendly recycling in its product descriptions.

2. Outdoor adventure equipment: a tough barrier to conquer nature

Facing harsh outdoor environments, nylon shows unparalleled value. Its high wear resistance, tear resistance and excellent waterproofness (especially after coating) make it the mainstay of mountaineering backpacks, tent tents and sleeping bag fabrics. Nylon fabrics certified by the American Society for Testing and Materials (ASTM) standards are the key basis for ensuring the reliability of outdoor equipment. Moreover, due to its lightweight characteristics, it greatly reduces the weight of explorers.

3. Comfortable home space: a beautiful and durable life partner

Nylon has become an important material for improving home quality with its soft touch, easy cleaning and durability. From curtains with elegant drape and sun resistance, to sofa covers that retain their color and shape after repeated washing, wear-resistant bedspreads and carpets, nylon meets aesthetic needs while greatly reducing daily maintenance costs. Its anti-fouling properties are especially suitable for families with children or pets.

4. The core of the automotive industry: lightweight and strong driving force

In the wave of automobiles pursuing lightweight and energy conservation and emission reduction, nylon engineering plastics (such as PA6, PA66) play a revolutionary role. From engine peripheral parts (intake manifolds, cooling system parts) that withstand high temperature and high pressure, sturdy body structures, to seat frames that provide support and comfort, nylon’s high strength, wear resistance, oil resistance and chemical corrosion resistance are crucial. According to research, nylon materials have accounted for about 35% of the total amount of automotive plastics, and are the core force to achieve the goal of lightweighting automobiles.

5. Electronic and electrical safety: insulation guard of precision equipment

In the field of precise and highly safe electronic and electrical equipment, nylon stands out for its excellent electrical insulation, heat and flame retardancy (such as flame retardant reinforced nylon) and dimensional stability. It is an ideal material for manufacturing insulation layers and sheaths of various wires and cables, effectively preventing short circuit risks. Nylon is also commonly used in the manufacture of key components such as connectors, switch housings, and relay coil skeletons to ensure the stable operation of equipment in complex environments. The International Electrotechnical Commission (IEC) standard has strict requirements on the performance of electronic insulation materials, and nylon is one of the important compliant materials.

6. Aerospace soaring: reliable bones in the sky

The aerospace field has almost stringent requirements on material performance. Nylon and its composite materials (such as carbon fiber reinforced nylon) have won a place with their excellent specific strength (ratio of strength to density), fatigue resistance and weather resistance. It is used in aircraft interior panels, various brackets, connectors, cable management components, and even drone structural parts. Its lightweight characteristics have made a significant contribution to reducing the weight of aircraft and improving fuel efficiency. The European Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) of the United States have a strict certification system for aviation materials.

7. Sports and competitive equipment: strong support for performance breakthroughs

In the sports world that pursues extreme performance, nylon provides key support. High-strength nylon monofilament is the core of tennis racket strings, badminton racket strings, and fishing lines, providing accurate hitting feedback and strong tensile properties. Basketball nets, football goal nets, etc. rely on its durability. Sports shoe uppers and high-performance sports socks use their lightness, breathability, wear resistance and good wrapping to help athletes improve their performance and reduce the risk of injury. The International Tennis Federation (ITF) has clearly defined the specifications of the racket strings used in competitions, and nylon strings are the mainstream choice.

8. Cornerstone of industrial manufacturing: wear-resistant gears with efficient operation

Beyond daily consumer goods, nylon is also the “wear-resistant champion” in the industrial field. Its self-lubricating properties, high mechanical strength and fatigue resistance make it the preferred material for manufacturing gears, bearings, pulleys, conveyor belt components, wear-resistant bushings, etc. It is widely used in agricultural machinery, food processing equipment, and textile machinery, significantly reducing noise, reducing maintenance frequency, and improving the overall life and operating efficiency of equipment. The report of the American Plastics Industry Association (PLASTICS) emphasizes the core role of high-performance engineering plastics (including special nylon) in promoting the development of advanced manufacturing.

Looking at the application map of nylon, its extraordinary value comes from the exquisite balance of multiple needs – strength and flexibility, lightness and durability, and function and cost. From the comfortable touch of clothing to the tough bones of aircraft parts, from the safe protection of insulated wires to the silent operation of industrial gears, nylon has built the invisible veins of modern civilization as a “technological fabric”.

With the continuous breakthroughs in material technology, bio-based nylon reduces carbon footprint, smart nylon responds to environmental changes, and 3D printing expands the boundaries of design – the evolution of the nylon family is opening up a broader space for sustainable development and innovative applications. It is not only the brilliant crystallization of yesterday’s laboratory, but also the indispensable resilient silk that drives the world of tomorrow.

The King of Materials’ Resilience Map

- Apparel Front: Moisture-absorbing and quick-drying, wear-resistant and wrinkle-resistant, protecting both sports and daily life

- Outdoor Armor: Wear-resistant and tear-resistant, waterproof and lightweight, a barrier to conquer nature

- Home Art: Soft, easy to clean and durable, weaving a comfortable and aesthetic space

- Automotive Bones: Lightweight, strong and corrosion-resistant, driving an energy-saving future

- Electronic Shield: Insulation, heat-resistant and flame-retardant, invisible guard for precision equipment

- Sky Wings: High specific strength and weather resistance, lifting aircraft to soar into the sky

- Sports Engine: High-strength tensile and wear-resistant, empowering competition to break through limits

- Industrial Gear: Self-lubricating and fatigue-resistant, silent and efficient operation