はじめに

ナイロン は、自動車部品から繊維製品に至るまで、幅広い用途に使用される最も汎用性の高いエンジニアリング・プラスチックのひとつです。応力、摩擦、摩耗に耐える能力を持つことから、多くの産業で好んで使用されています。ナイロンの性能と耐久性を決定づける重要な要素のひとつが、その弾性率です。 弾性率.この特性は、応力下での変形に抵抗する材料の能力を定義し、強度、柔軟性、長期耐久性に影響を与えます。ナイロンの弾性率を理解することは、さまざまな用途での使用を最適化する上で極めて重要です。この記事では、ナイロンの弾性率を向上させ、試験し、測定するためのヒントとコツを探り、あなたのプロジェクトの要求を満たすようにします。

ナイロンの弾性率を理解する

A.ナイロン弾性率の定義

ナイロンの弾性率(モジュラス)とは、力を加えたときの材料の弾性変形に対する抵抗力のことです。これは基本的な機械的特性であり、与えられた荷重のもとで材料がどの程度伸び縮みするかを示すものです。ナイロンの場合、弾性率は永久変形することなく機械的応力に耐えられるかどうかを判断するのに役立ちます。弾性率が高いほど材料は硬くなり、高い強度と変形に対する抵抗力を必要とする用途に適しています。

B.材料特性の決定における弾性率の重要性

ナイロンの弾性率は、応力下での材料全体の挙動を決定する上で重要な役割を果たします。弾性率の高いナイロンは、曲がったり、伸びたり、歪んだりしにくく、構造部品や精密用途に最適です。一方、弾性率の低いナイロンは柔軟性が高く、衣料品や梱包材、その他の柔軟な部品に不可欠です。ナイロンの弾性率を理解することは、メーカーがナイロンを特定の用途に合わせて調整し、潜在的な不具合や非効率を最小限に抑えながら性能を最適化するのに役立ちます。

C.ナイロンの弾性率に影響する因子

ナイロンの弾性率には、以下のようないくつかの要因が影響する:

- ナイロンのグレード さまざまなグレードのナイロンがある。 ナイロン6, ナイロン66や強化ナイロンは、分子構造や添加剤によってさまざまな弾性率を持つ。

- 温度だ: ナイロンの弾性率は温度の上昇とともに低下し、剛性の低下や荷重下での変形につながる。

- 水分含有量: ナイロンは吸湿性があり、水分を吸収します。水分の存在は素材の弾性率を低下させ、剛性の低下につながります。

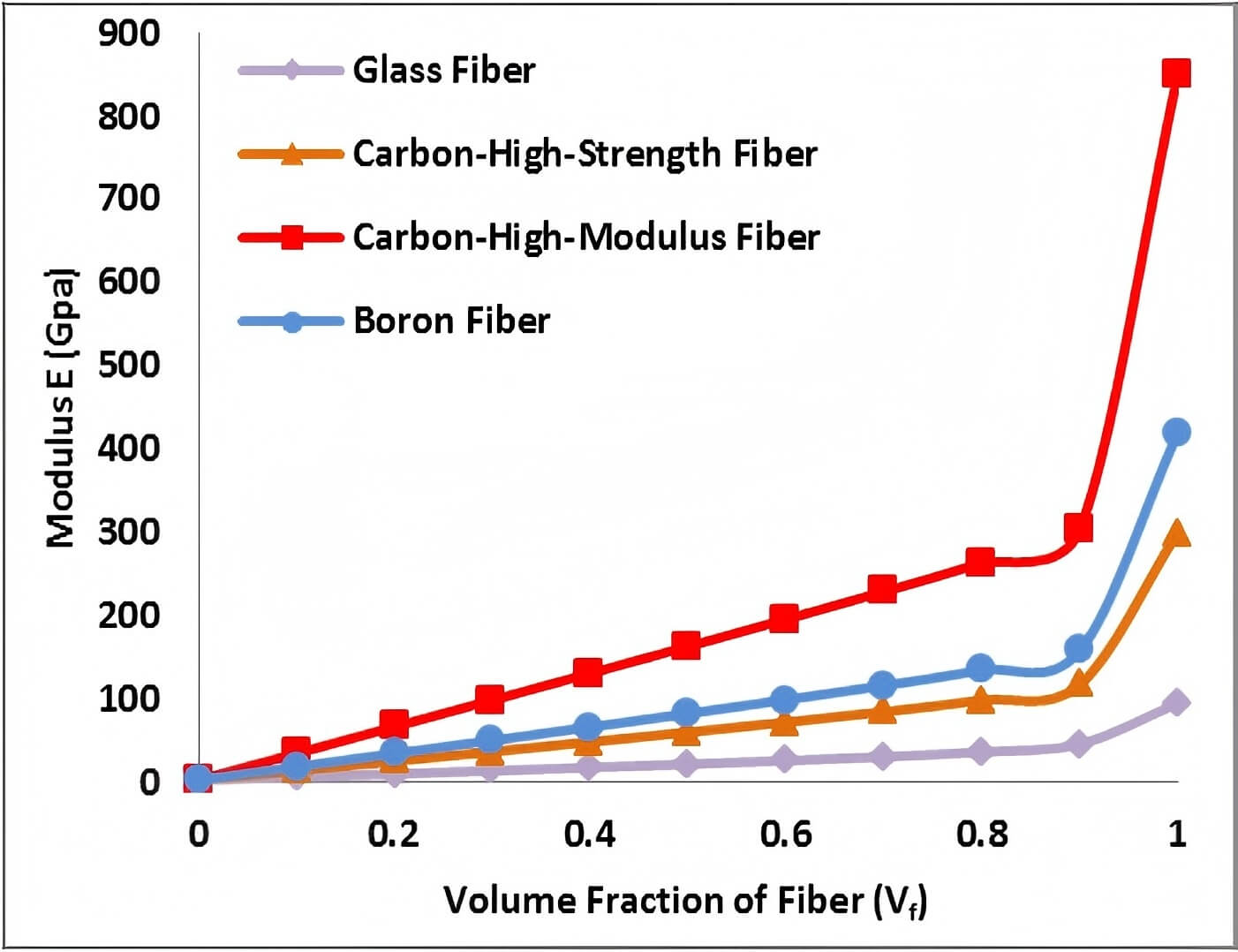

- 添加物と充填剤: ガラス繊維、炭素繊維、その他のフィラーなどの添加剤を組み込むことで、ナイロンの弾性率を大きく変化させることができ、必要に応じて硬くしたり、柔軟にしたりすることができる。

ナイロンの弾性率を向上させるためのヒント

A.ナイロン・グレードの適切な選択

ナイロンの弾性率を向上させる最初のステップは、適切なグレードを選択することです。ナイロンのグレードによって弾性率が異なるため、適切なものを選ぶことが非常に重要です。例えば、ナイロン66は一般にナイロン6に比べて弾性率が高く、剛性と強度を必要とする用途に適しています。さらに、ガラス繊維や炭素繊維で強化したナイロンは、弾性率を高めることができ、より剛性と耐久性に優れた素材になります。

B.モジュラスを高める熱処理技術

アニーリングとも呼ばれる熱処理は、ナイロンの弾性率を向上させる一般的な方法である。材料を特定の温度に加熱した後、制御された方法で冷却することにより、ナイロンの分子構造を変化させ、剛性と変形に対する抵抗力を高めることができます。熱処理工程は、ポリマー鎖をより効果的に整列させ、より剛性の高い安定した素材へと導きます。ただし、材料の劣化を避けるため、温度と冷却速度を注意深く制御することが重要である。

C.剛性を高めるための添加剤の使用

ガラス繊維、炭素繊維、その他の補強材のような添加剤を組み込むことは、ナイロンの弾性率を高める効果的な方法です。これらの添加剤は、構造的なサポートを追加し、素材全体の剛性を向上させます。例えば、ガラス繊維入りナイロンは、標準的なナイロンと比較して著しく高い弾性率を有し、自動車部品、ギア、構造部品などの高応力用途に最適です。

ナイロン弾性率の試験と測定のコツ

A.モジュラス評価のための様々な試験方法

ナイロンの弾性率の評価には、次のようないくつかの試験方法があります:

- 引張試験: 最も一般的な方法のひとつである引張試験は、材料が引き伸ばされたときにどのように反応するかを測定するものである。引張力を加え、そのひずみを測定することで、応力-ひずみ曲線から弾性率を算出することができる。

- 曲げ試験: この方法は曲げに対する材料の応答を評価します。この方法は、材料に曲げ応力がかかりやすい用途でナイロンの弾性率を評価するのに特に有効です。

- 動的機械分析(DMA): DMAは、振動する力に対する材料の応答を測定し、異なる温度と周波数における弾性率を決定するために使用することができます。

B.品質管理における正確な測定の重要性

弾性率を正確に測定することは、ナイロン製品の品質と一貫性を維持するために極めて重要です。弾性率の偏差は、性能不足、材料の不具合、あるいは顧客の不満足につながります。定期的な試験により、ナイロンが各用途の要求仕様を満たしていることを確認し、材料が生産に使用される前にメーカーが矛盾を特定して対処するのに役立ちます。

C.異なる弾性率試験技術の比較

それぞれの弾性率試験法には利点と限界があります。例えば、引張試験は簡単で広く使用されていますが、温度変化に非常に敏感な材料には理想的でないかもしれません。曲げ試験は、特定の用途には有用ですが、あらゆる条件下での材料の性能をそれほど詳細に把握できない場合があります。さまざまな試験方法を比較することで、メーカーはそれぞれのニーズに最も適した技術を選択することができます。

ナイロンの弾性率に関する一般的な質問

A.ナイロンの弾性率に温度はどのように影響するか?

温度はナイロンの弾性率に大きな影響を与える。温度が上昇すると、材料はより柔軟になり、弾性率が低下します。高温になるとナイロンは軟化し、応力による変形を起こすことがあります。これは、自動車や工業用など、ナイロンが高温にさらされる用途では特に重要です。ナイロンの熱特性を理解し、適切なグレードを選択することで、これらの影響を軽減することができます。

B.ナイロンの弾性率は製造後に調整できますか?

ナイロンの弾性率は、グレードの選択、添加剤、加工技術など、製造時のさまざまな要因によって影響を受けるが、製造後に弾性率を調整することは難しい。ナイロンはいったん成形または押出し加工されると、その分子構造はほぼ固定されます。しかし、熱処理のような特定の後加工技術を用いれば、弾性率をわずかに変化させることができる。

C.特定の用途におけるナイロンの高弾性率の意味は?

ナイロンの弾性率が高いということは、その材料がより硬く、より変形しにくいことを意味します。自動車部品、歯車、構造部品などの用途では、材料がその形状を失うことなく機械的応力に耐えるためには、より高い弾性率が不可欠です。しかし、弾性率が高くなると材料の柔軟性が低下するため、柔軟性や耐衝撃性が必要な用途では好ましくない場合があります。従って、用途に適した弾性率を選択することは、剛性と柔軟性の望ましいバランスを達成する上で極めて重要です。

結論

ナイロンの弾性率は、材料の性能とさまざまな用途への適合性を決定する重要な要素です。自動車部品、消費者製品、工業部品のいずれを扱う場合でも、ナイロンの弾性率を理解し最適化することは、製品の品質と耐久性に大きな影響を与えます。適切なグレードを選択し、熱処理を施し、添加剤を配合することで、メーカーは特定の要件を満たすように弾性率を向上させることができます。さらに、一貫した性能を維持するためには、正確な試験と測定が不可欠です。正しい知識と技術があれば、ナイロン製品が最高の性能を発揮し、顧客のニーズに応えることができます。