NYLON 12 FEATURE

✔ Durable

✔ High Strength

✔ Chemical Resistant

✔ Dimensionally Stable

✔ Low Moisture Absorption

Nylon 12, also known as PA12 plastic, is a high-performance engineering thermoplastic renowned for its exceptional blend of strength, flexibility, and resilience. This advanced material offers a compelling solution for a wide range of demanding applications, making it a top choice for designers, engineers, and manufacturers seeking unparalleled performance.

Unmatched Performance Characteristics:

Benefits Across Industries:

PA12 GF25 is a type of nylon plastic reinforced with 25% glass fibers for increased strength and heat resistance.

PA12 GF30 is a type of nylon plastic reinforced with 30% glass fibers for increased strength and heat resistance.

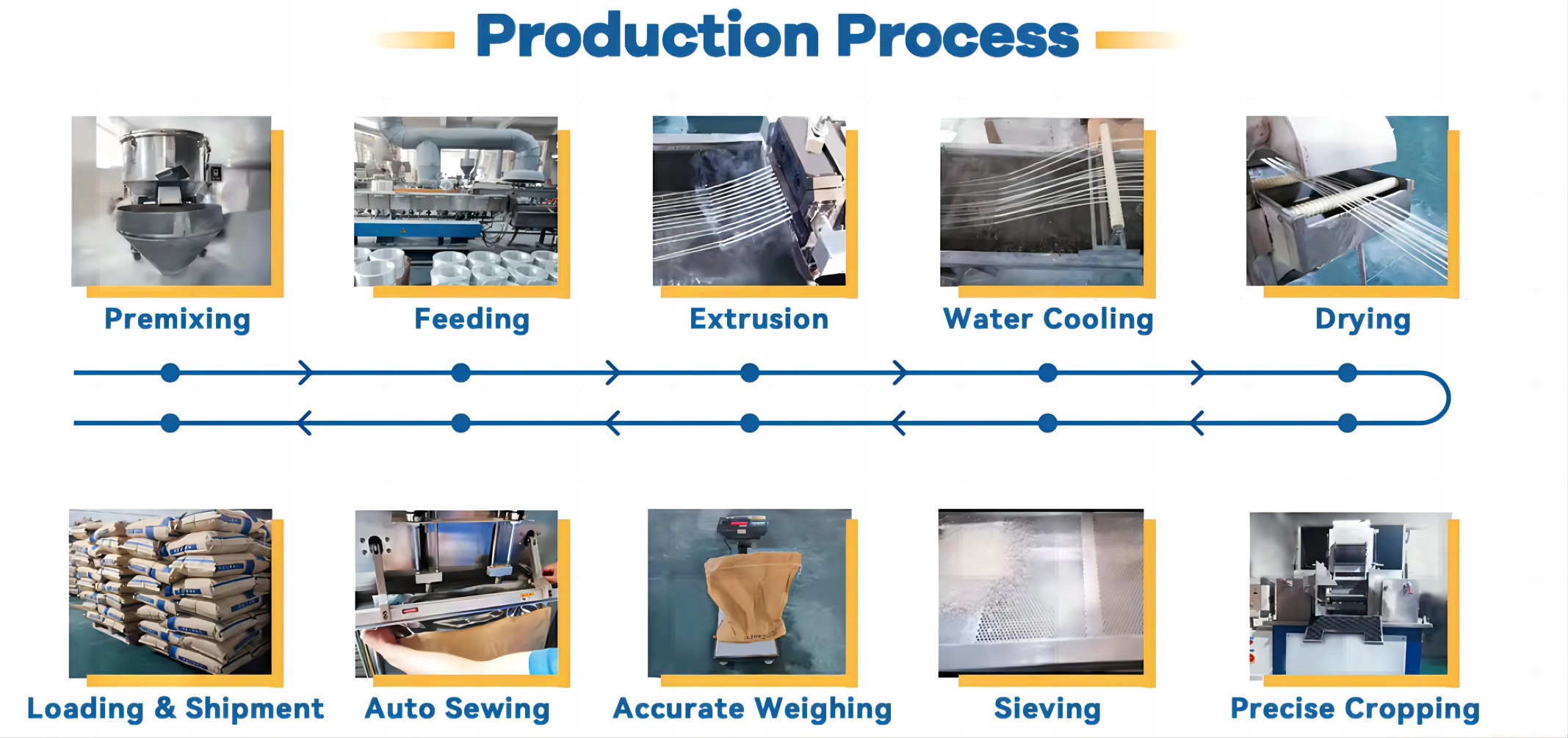

High-performance PA12 nylon converted into durable products through a cost-effective extrusion process.

PA12 compound extrusion creates strong, lightweight parts by combining PA12 nylon with performance-boosting additives.

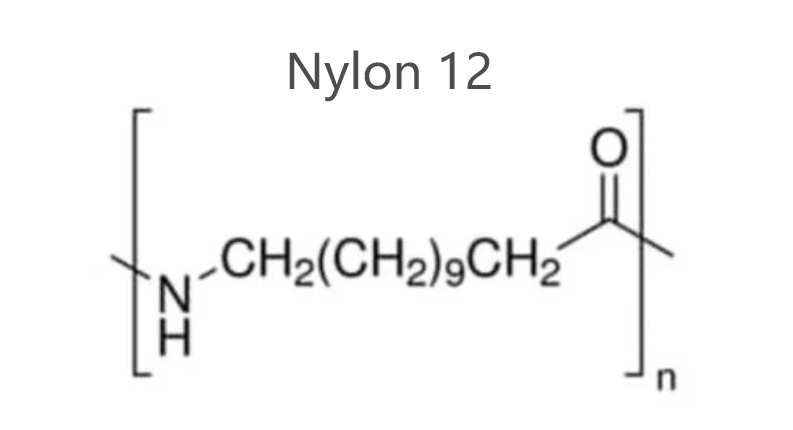

Nylon 12, also known as polyamide 12 (PA12), is a type of engineering plastic known for its strength, flexibility, and low friction.

Nylon plastic boasts several advantages:

There are many types of nylon, each with its own properties. Nylon 12 offers a good balance of strength, flexibility, and low friction compared to some nylons like Nylon 6 (PA6) which can be stiffer. However, Nylon 6 may offer better high-temperature performance.