PA6 Cold Resistance

PA6, or nylon 6, offers good inherent cold resistance. This means it maintains its strength and functionality at relatively low temperatures. While not the most extreme option, unmodified PA6 cold resistance can perform well in cold environments.

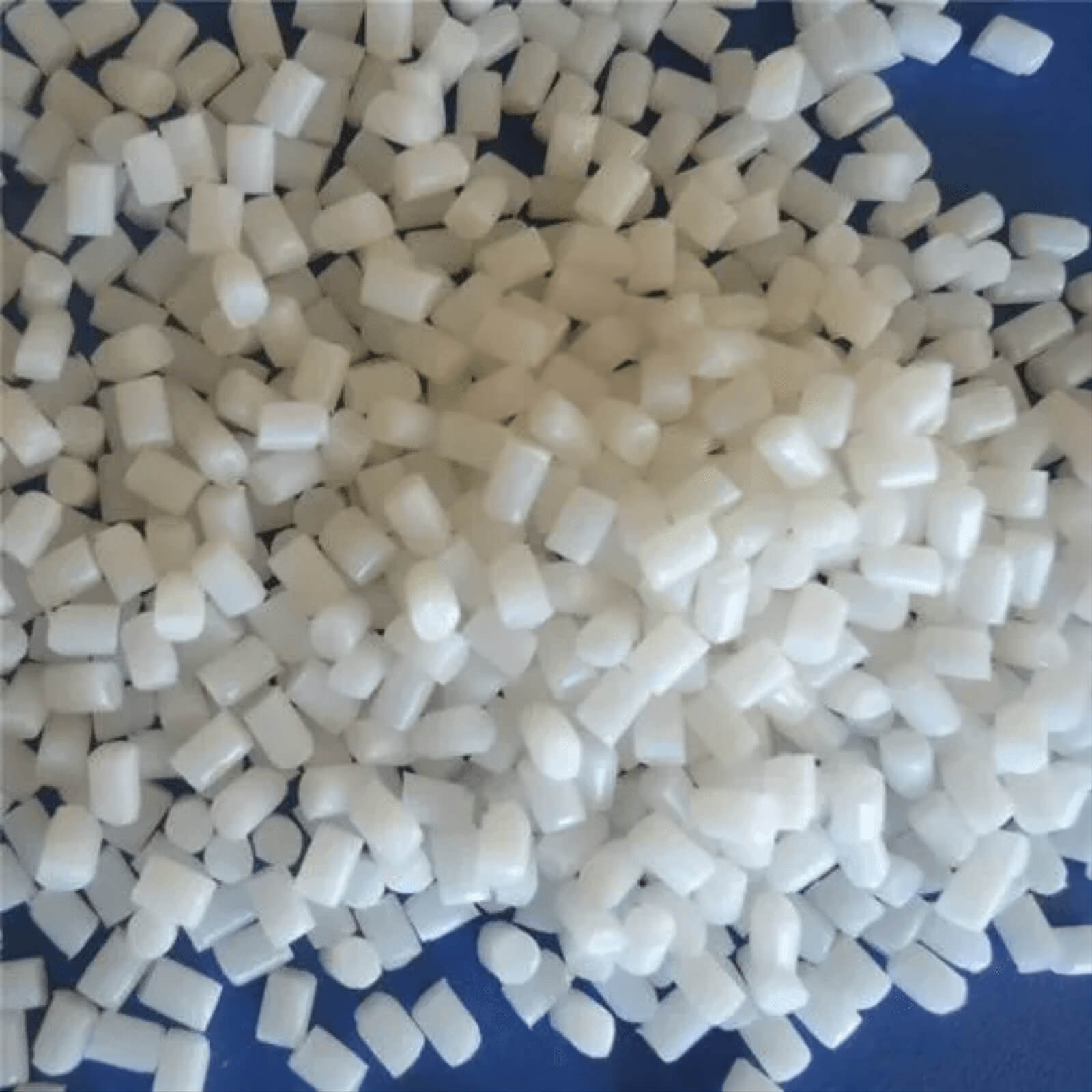

Breif Introduction of PA6 Cold Resistance

PA6, also known as nylon 6, is a widely used engineering plastic known for its well-rounded performance. One of its key strengths is its inherent PA6 cold resistance. This translates to PA6 maintaining its strength and functionality at relatively low temperatures. While not the most extreme option for frigid environments, unmodified PA6 can perform well without becoming brittle or breaking.

However, it’s important to note that PA6 temperature resistance can vary depending on the specific grade and any additives used. For exceptionally cold applications, there are modified PA6 formulations designed with enhanced low-temperature performance.

Beyond its cold resistance, PA6 also boasts good pa6 chemical resistance. This makes it a versatile material that can withstand exposure to a variety of chemicals without degradation. This, combined with its good mechanical properties, makes PA6 a valuable choice for applications in various industries.

The Popular Products of PA6 Cold Resistance

Snowboard

Mine Equipment Parts

Military Equipment

PA6 Cold Resistance Data

| PA6 Cold Resistance Datasheet | |||

| Properties | Test conditions | Test unit | Test values |

| Physical properties | |||

| Density | ISO 1183 | g/cm3 | 1.37 |

| Shrinkage | |||

| MD | ISO 294-4 | % | 0.4-0.7 |

| Ash content | ISO 1762 | % | 30 |

| Impact performance | |||

| Missing impact strength of the cantilever beam | – | ||

| 23°C | ISO 180 | J/m | 39 |

| Thermal performance | |||

| Thermal deformation temperature | |||

| 1.8 MPa, unannealed | ISO 306 | °C | 180 |

| Melting temperature | ISO 1133 | °C | 220 |

| Electrical properties | |||

| Volumetric electropositive rate | IEC 93-1983 | ohms·cm | 1.0E+13 to 1.0E+15 |

| Dielectric strength | IEC 60243 | kV/mm | 3.8 |

| Mechanical properties | |||

| Rockwell hardness | 120 | ||

| Grade R | – | – | – |

| Tensile strength | – | ||

| Yield | ISO 527-2 | Mpa | 88.3 |

| Tensile strain | – | ||

| Break | ISO 527-2 | % | 7.0 |

| Flexural modulus | ISO 178 | Mpa | 4900 |

| Flexural strength | ISO 178 | Mpa | 123 |