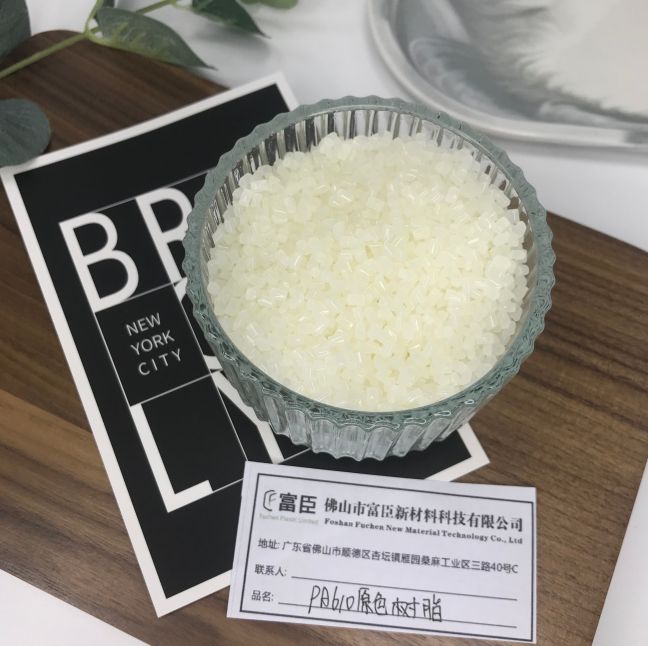

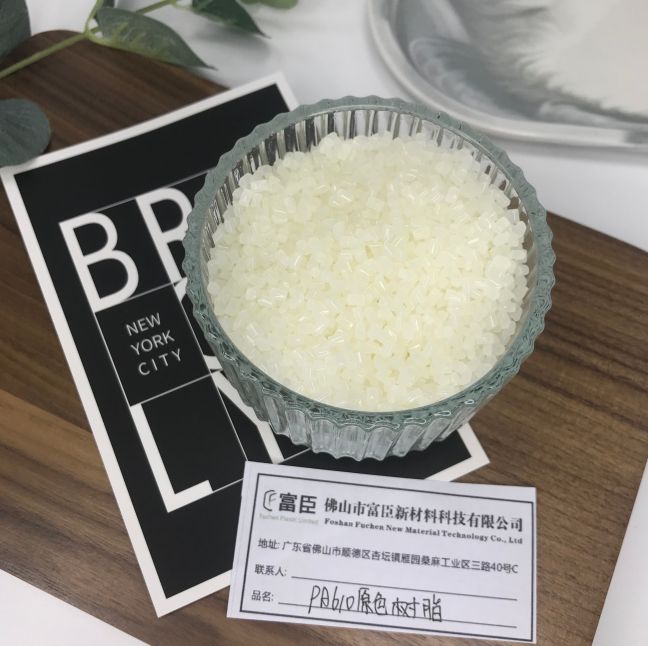

PA610 Natural Resin

In addition to the characteristics of high strength, wear resistance and oil resistance, PA610 natural resin also has low water absorption, good dimensional stability, and excellent electrical properties.

GET FREE QUOTATION

In addition to the characteristics of high strength, wear resistance and oil resistance, PA610 natural resin also has low water absorption, good dimensional stability, and excellent electrical properties.

GET FREE QUOTATIONPA610 natural resin, also known as polyamide 610, is a high-performance plastic known for its exceptional combination of mechanical properties. It boasts superior strength and stiffness, making it ideal for demanding applications.

PA610 shines in high-heat environments due to its excellent thermal resistance, which allows it to maintain its shape and performance at elevated temperatures. An additional benefit is its inherent flame retardancy, making it a suitable choice for safety-critical applications. Furthermore, PA610 offers good chemical resistance to various oils, greases, and fuels, enhancing its versatility. Finally, this resin exhibits good dimensional stability, minimizing warping or shrinkage over time.

Overall, PA610 natural resin is a compelling choice for components requiring a balance of strength, heat tolerance, flame retardancy, and chemical resistance.