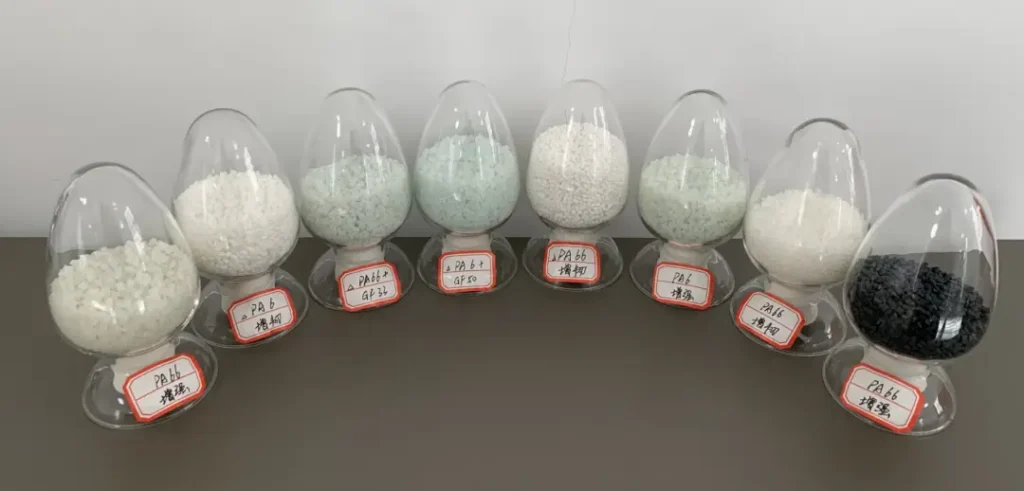

البولي أميدات، والمعروفة باسم النايلونات، هي مجموعة واسعة من اللدائن الحرارية الهندسية التي تُقدّر بقوتها وتعدد استخداماتها ومقاومتها الكيميائية. وضمن هذه المجموعة، يعد كل من PA6 و PA66 عضوين بارزين يمكن أن يسببان التباسًا بسبب تشابه أسمائهما وموادهما الأساسية المشتركة. يتعمق هذا الدليل في الفروق الرئيسية بين PA6 و PA66 لتمكين مهندسي المواد من اتخاذ خيارات مستنيرة لمشاريعهم.

أوجه التشابه PA6 مقابل PA66

- يعتبر كل من PA6 و PA66 من اللدائن الحرارية القوية المقاومة للتآكل والمقاومة للمواد الكيميائية.

- وتستخدم على نطاق واسع في قطع غيار السيارات والسلع الاستهلاكية والتطبيقات الصناعية المختلفة.

PA6 (بولي أميد 6):

- الإيجابيات:أسهل في المعالجة بسبب انخفاض درجة الانصهار، مما يؤدي إلى انخفاض تكاليف التصنيع. صلابة ومقاومة جيدة للصدمات. أداء متفوق في التطبيقات التي تتعرض للرطوبة بسبب ثبات مائي أفضل.

- السلبيات:مقاومة أقل لدرجات الحرارة مقارنةً بمادة PA66، مما يجعلها أكثر عرضة للتشوه تحت الحرارة العالية. يمكن أن يؤدي ارتفاع امتصاص الرطوبة إلى تغيرات في الأبعاد.

PA66 (بولي أميد 6،6):

- الإيجابيات:مقاومة فائقة لدرجات الحرارة وقوة ميكانيكية عالية، مما يجعلها مثالية للاستخدامات الصعبة. يحافظ على أداء جيد في درجات الحرارة العالية. يمكن أن يسهم انخفاض امتصاص الرطوبة في تحسين ثبات الأبعاد.

- السلبيات:أكثر صعوبة في المعالجة بسبب ارتفاع درجة الانصهار، مما قد يزيد من تكاليف التصنيع. أغلى من PA6.

كيفية اختيار المادة المناسبة:

- أداء وقوة في درجات الحرارة العالية:PA66 هو الفائز الواضح.

- سهولة المعالجة والتكلفة:تقدم PA6 ميزة PA6.

- مقاومة الرطوبة:قد يكون PA6 خيارًا أفضل لثباته المائي، ولكن ضع في اعتبارك احتياجات امتصاص الرطوبة الكلية لثبات الأبعاد.

PA6 مقابل PA66 اعتبارات إضافية:

- مثبطات اللهب:تتوفر بعض الأشكال المختلفة من كل من PA6 و PA66 مع إضافات مثبطة للهب حسب متطلبات الاستخدام.

- خواص الاحتكاك:قد توفر PA6 خواص تشحيم ذاتي فائقة في بعض التطبيقات مقارنةً ب PA66.

- مقاومة التعب والإجهاد:تُظهر PA66 بشكل عام مقاومة أفضل للإجهاد في ظروف التحميل الدوري.

يتوقف اختيار المادة المثلى بين PA6 و PA66 على المتطلبات المحددة لاستخدامك. قيّم بعناية عوامل مثل مقاومة درجات الحرارة، واحتياجات المعالجة، وقيود التكلفة، والتعرض للرطوبة، ومتطلبات القابلية للاشتعال، والسلوك الاحتكاكي، ومقاومة التعب. من خلال فهم الخصائص المميزة لكل من PA6 و PA66، يمكن لمهندسي المواد اتخاذ قرارات مستنيرة تضمن نجاح مشاريعهم.