NEILONA 66 FUNKCIJA

✔ Zema mitruma absorbcija

✔ Augsta stiepes izturība

✔ Laba izturība pret nodilumu

✔ Laba elektriskā izolācija

Neilons 66, pazīstams arī kā PA66, ir populāra inženiertehniskā plastmasa, ko augstu vērtē tās izcilas izturības, stingrības, karstumizturības un nodilumizturības dēļ. Pateicoties šīm īpašībām, šis materiāls ir piemērots visdažādākajām pielietojuma jomām dažādās nozarēs.

Neilona 66 variācijas īpašām vajadzībām:

PA66 GF13: Šajā variantā ir iestrādāts 13% stikla šķiedras stiegrojums, kas palielina mehānisko izturību un stingrību salīdzinājumā ar standarta PA66.

VOSS PA66 GF35 un Bosch PA66 GF30: Šīs ir zīmolam raksturīgas variācijas, ko, iespējams, izstrādājuši attiecīgi Voss un Bosch. Tajos ir 35% un 30% stikla šķiedras stiegrojums, kas, iespējams, paredzēts lietojumiem, kuros nepieciešama lielāka izturība.

Pareizā neilona 66 varianta izvēle:

Optimālā izvēle starp šiem neilona 66 variantiem ir atkarīga no jūsu projekta specifiskajām prasībām. Ņemiet vērā šādus faktorus:

PA66 sveķi ir augstas veiktspējas termoplasts, kas pazīstams ar savām izcilajām mehāniskajām īpašībām.

Spēcīga, karstumizturīga plastmasa, kas pastiprināta ar sīkām stikla šķiedrām, lai palielinātu stingrību un izturību.

Augstas stiprības PA66, kas papildināts ar pastiprinošiem materiāliem, lai nodrošinātu izcilu stingrību, izturību un karstumizturību.

Ugunsizturīga PA66 plastmasa ar pievienotiem antipirēniem paaugstinātai drošībai sarežģītos lietojumos.

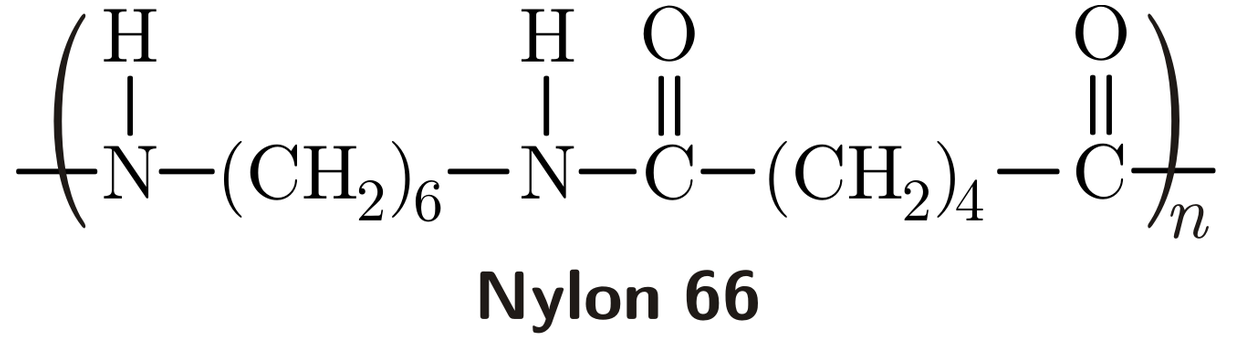

Neilons 66 ir neilona veids, sintētisks polimērs, kas pazīstams ar savu izturību, elastību un daudzpusību. Tas veidojas, reaģējot divām dažādām ķīmiskām vielām - heksametilēndiamīnam un adipīnskābei.

Lai gan neilons 6 un neilons 66 ir līdzīgi, tiem ir dažas būtiskas atšķirības:

Pateicoties PA66 īpašībām, tam ir plašs pielietojums. Šeit ir daži piemēri: