High-Performance Nylon 6

Nylon 6 (PA6) is a workhorse plastic known for its strength, elasticity, and wear resistance. We offer a variety of PA6 options to meet your specific needs:

- Unreinforced PA6: The base material, offering a balance of properties for everyday applications.

- PA6+GF (Glass Fiber Reinforced): Increase strength and stiffness with various fiber content options like PA6 GF30 (30% glass fiber) and PA6 GF50 (50% glass fiber). Ideal for high-load bearing parts.

- PA6 GB (Glass Bead Reinforced): PA6 GB20 GF10, for example, offers improved dimensional stability and wear resistance compared to unreinforced PA6. The 10% glass bead content maintains a good strength-to-weight ratio.

Our diverse selection of PA6 plastics ensures you find the perfect fit for your project. Whether you need the versatility of unreinforced PA6 or the enhanced strength of glass fiber or bead reinforced options, we have you covered. Contact us today to discuss your project and explore our Nylon 6 solutions!

Types of Nylon 6

PA6 Glass Fiber

Strong plastic with glass fibers for enhanced performance in parts.

PA6 Flame Retardant

Fire-resistant PA6: Enhanced safety for nylon 6 with good properties.

PA6 Cold Resistance

PA6: Stays tough, even in frigid temps. Low-temperature performance.

FAQ of Nylon 6

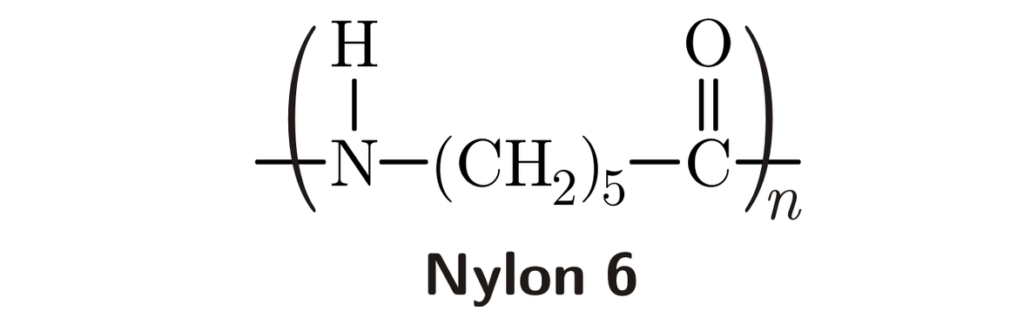

What is Nylon 6?

Nylon 6 is a type of thermoplastic polymer, known for its strength, elasticity, and abrasion resistance. It’s widely used in various applications due to its versatility.

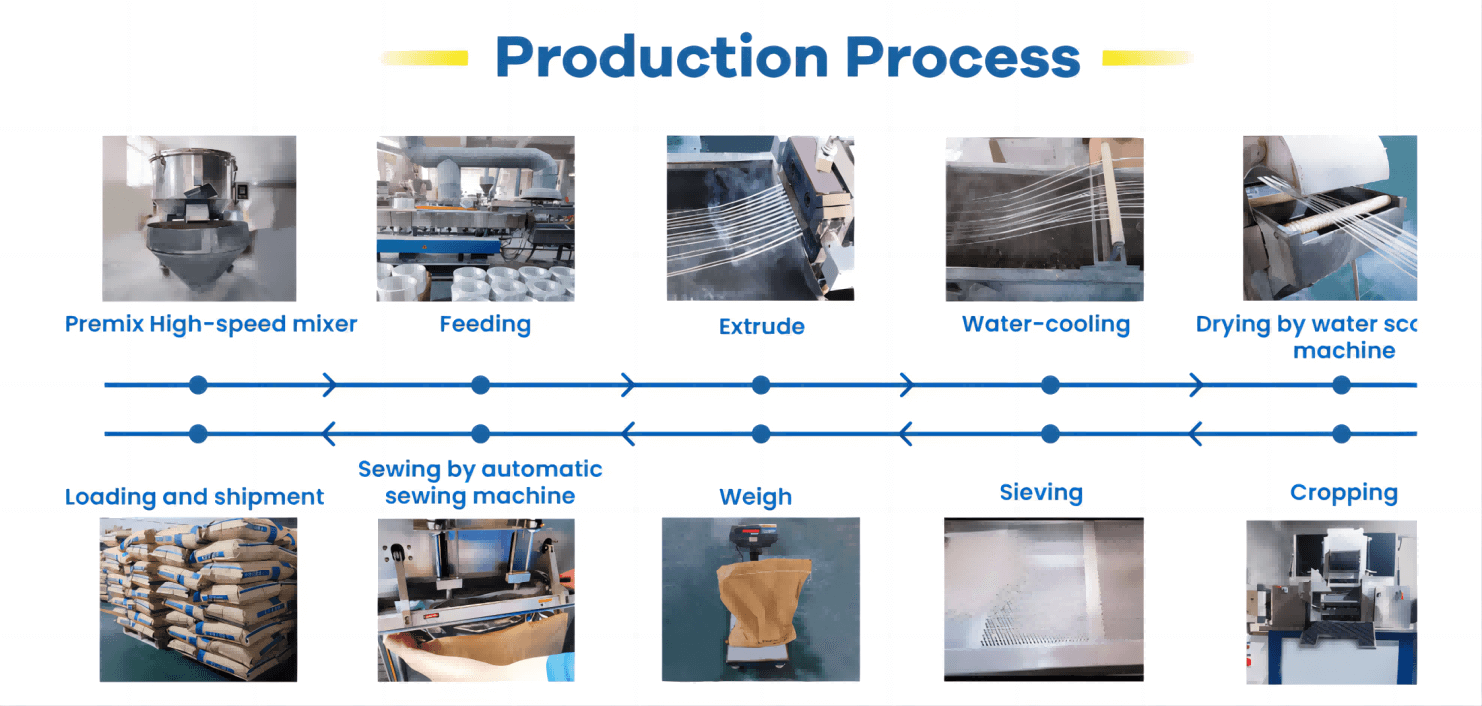

How is Nylon 6 made?

Nylon 6 is typically produced through a process called cast polymerization. Here’s a simplified breakdown:

- Monomer preparation: Caprolactam, the building block for Nylon 6, is obtained.

- Melting: Caprolactam is melted and converted into a molten ring.

- Polymerization: The ring-shaped molecules react and bond to form long polymer chains of Nylon 6.

- Shaping: The molten Nylon 6 is poured into molds and allowed to solidify into the desired shape.

This process allows for good dimensional stability in the final product compared to some other methods.

How does Nylon 6 differ from Nylon 66?

Both are nylons, but with slight variations in their chemical structure. This leads to some key differences:

- Water absorption: Nylon 6 absorbs more moisture, affecting dimensional stability and heat deflection temperature.

- Heat resistance: Nylon 66 has a higher heat deflection temperature due to lower water absorption.

- Chemical resistance: Nylon 66 offers slightly better resistance to some chemicals.

What are the applications of Nylon 6?

Due to its properties, Nylon 6 has numerous applications, including:

- Fibers: For textiles like carpets, clothing, and sportswear.

- Engineering parts: Gears, bearings, and other components requiring wear resistance.

- Automotive parts: Components like fan shrouds and engine parts.

- Electrical applications: Insulation for wires and cables.

What's the difference between PA6+GF30, PA6 GB20 GF10, and PA6 GF50?

These notations all refer to variations of PA6 plastic filled with glass fibers. The key difference lies in the percentage of glass fiber content:

- PA6+GF30: This material contains 30% glass fibers by weight. It offers a good balance between strength, stiffness, and weight.

- PA6 GB20 GF10: This designation is a bit different. PA6 GB20 likely refers to a specific grade of PA6 with additional properties (GB20 could be a manufacturer’s code). It also contains 10% glass fibers. This material might offer slightly different properties compared to a standard PA6+GF10 due to the specific PA6 grade.

- PA6 GF50: This material boasts the highest glass fiber content (50%) among the options listed. It will be the strongest and stiffest but also the heaviest and potentially more brittle.