خاصية النايلون 12

✔ متين

✔ قوة عالية

✔ مقاوم للمواد الكيميائية

✔ مستقر الأبعاد

✔ امتصاص منخفض للرطوبة

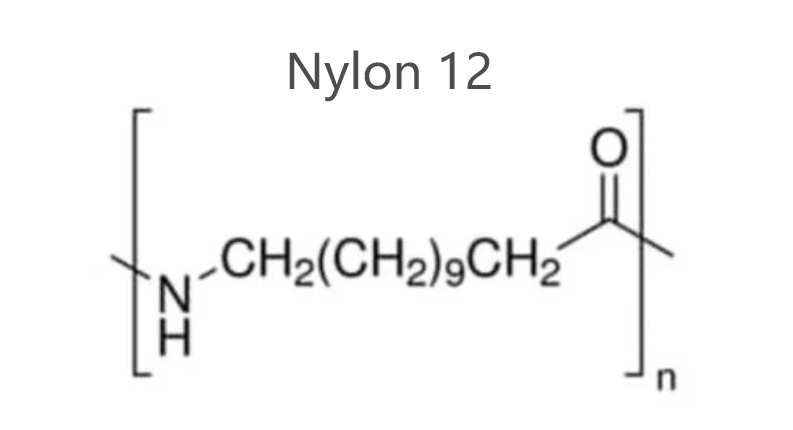

نايلون 12, يُعرف أيضًا باسم بلاستيك PA12، وهو بلاستيك حراري هندسي عالي الأداء يشتهر بمزيج استثنائي من القوة والمرونة والمرونة. توفر هذه المادة المتطورة حلاً مقنعاً لمجموعة كبيرة من التطبيقات المتطلبة، مما يجعلها الخيار الأفضل للمصممين والمهندسين والمصنعين الذين يبحثون عن أداء لا مثيل له.

خصائص أداء لا مثيل لها:

الفوائد عبر الصناعات:

PA12 GF25 هو نوع من بلاستيك النايلون المقوى بألياف زجاجية من نوع 25% لزيادة القوة ومقاومة الحرارة.

PA12 GF30 هو نوع من بلاستيك النايلون المقوى بألياف زجاجية 30% لزيادة القوة ومقاومة الحرارة.

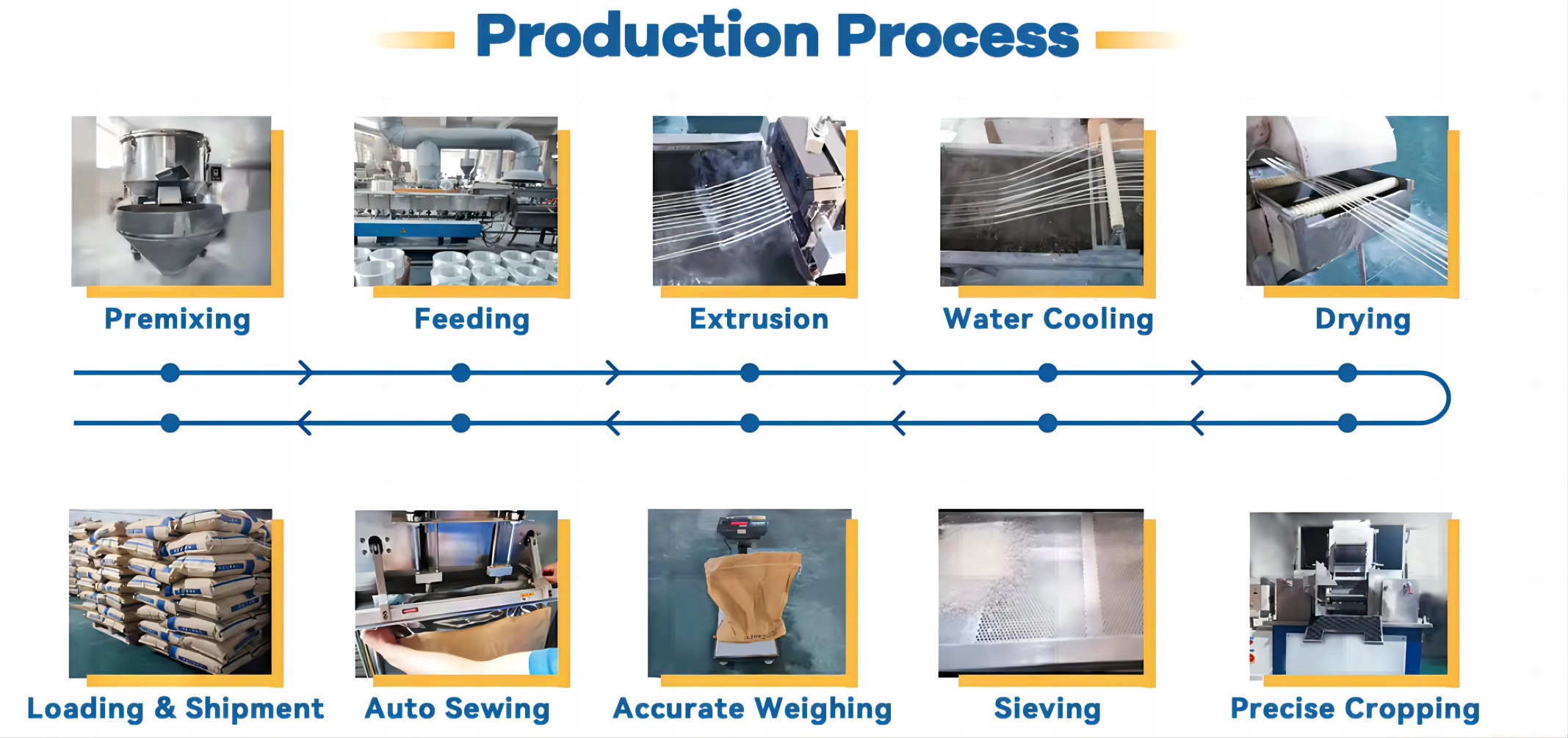

نايلون PA12 عالي الأداء يتم تحويله إلى منتجات متينة من خلال عملية بثق فعالة من حيث التكلفة.

يُنتج البثق المركب PA12 قطعاً قوية وخفيفة الوزن من خلال الجمع بين النايلون PA12 والإضافات المعززة للأداء.

النايلون 12، المعروف أيضًا باسم بولي أميد 12 (PA12)، هو نوع من البلاستيك الهندسي معروف بقوته ومرونته وانخفاض احتكاكه.

يتميز بلاستيك النايلون بالعديد من المزايا:

هناك العديد من أنواع النايلون، ولكل منها خصائصه الخاصة. يوفر النايلون 12 توازنًا جيدًا بين القوة والمرونة والاحتكاك المنخفض مقارنةً ببعض أنواع النايلون مثل النايلون 6 (PA6) الذي قد يكون أكثر صلابة. ومع ذلك، قد يوفر النايلون 6 أداءً أفضل في درجات الحرارة العالية.