Introduktion

Nylon er en af de mest alsidige og udbredte syntetiske polymerer, og blandt de forskellige typer skiller Nylon 11 og Nylon 12 sig ud med deres unikke egenskaber. Nylon 11 vs. nylon 12, begge materialer tilhører familien af alifatiske polyamider og giver forskellige fordele afhængigt af deres tilsigtede brug. At forstå forskellene mellem Nylon 11 og Nylon 12 er afgørende for at vælge det rigtige materiale til specifikke anvendelser. I denne artikel går vi i dybden med begge materialers kemiske egenskaber, fordele, ulemper og anvendelser i den virkelige verden, så du får en omfattende vejledning, der kan hjælpe dig med at træffe en informeret beslutning.

Egenskaber ved Nylon 11

Nylon 11også kendt som polyamid 11, er en biobaseret polymer, der primært stammer fra ricinusolie. Det er kendt for sin høje slagstyrke, fleksibilitet og fremragende kemiske resistens, hvilket gør det velegnet til en række krævende anvendelser. Her er en oversigt over dets vigtigste egenskaber:

Kemisk struktur og egenskaber

Nylon 11 har en langkædet molekylær struktur med 11 kulstofatomer i den gentagne enhed. Denne struktur bidrager til den forbedrede fleksibilitet, sejhed og modstandsdygtighed over for fugtabsorption. Det er mindre tilbøjeligt til hydrolyse sammenlignet med andre nyloner, hvilket gør det velegnet til våde miljøer.Anvendelser i forskellige brancher

Nylon 11 bruges ofte i bil-, rumfarts- og elindustrien, hvor dele udsættes for barske forhold. Det bruges til brændstofledninger, hydraulikslanger, elektriske stik og belægninger på grund af dets overlegne kemiske og termiske stabilitet.Fordele og ulemper

Fordele:- Høj kemisk resistens, især over for olier og brændstoffer.

- Fremragende ydeevne og fleksibilitet ved lave temperaturer.

- Biobaseret og mere miljøvenlig på grund af sin oprindelse i ricinusolie.

Ulemper:

- Relativt dyrt sammenlignet med andre nyloner.

- Kan være sværere at behandle i visse applikationer.

Egenskaber ved Nylon 12

Nylon 12eller polyamid 12, er et andet alifatisk polyamid, der er kendt for sin overlegne ydeevne i forskellige anvendelser. I modsætning til Nylon 11, som er biobaseret, stammer Nylon 12 typisk fra oliebaserede råmaterialer. Lad os udforske dets egenskaber:

Kemisk struktur og egenskaber

Nylon 12 har en kortere molekylær kæde end Nylon 11, med 12 kulstofatomer i den gentagne enhed. Det giver større fleksibilitet og lavere fugtabsorption. Nylon 12 udviser også forbedret dimensionsstabilitet og bedre modstandsdygtighed over for slitage.Anvendelser i forskellige brancher

Ligesom Nylon 11 bruges Nylon 12 i bilindustrien, industrien og den medicinske sektor. Det er almindeligt forekommende i produkter som slanger, brændstofledninger og fleksible film samt medicinsk udstyr som katetre og systemer til indgivelse af medicin.Fordele og ulemper

Fordele:- Lavere fugtabsorption end mange andre nyloner, hvilket giver bedre dimensionsstabilitet.

- Bedre slidstyrke og glattere overfladefinish.

- Mere omkostningseffektivt sammenlignet med Nylon 11.

Ulemper:

- Mindre modstandsdygtig over for olier og brændstoffer sammenlignet med Nylon 11.

- Mindre biobaseret, hvilket gør det mindre miljøvenligt end Nylon 11.

Sammenligning af Nylon 11 og Nylon 12

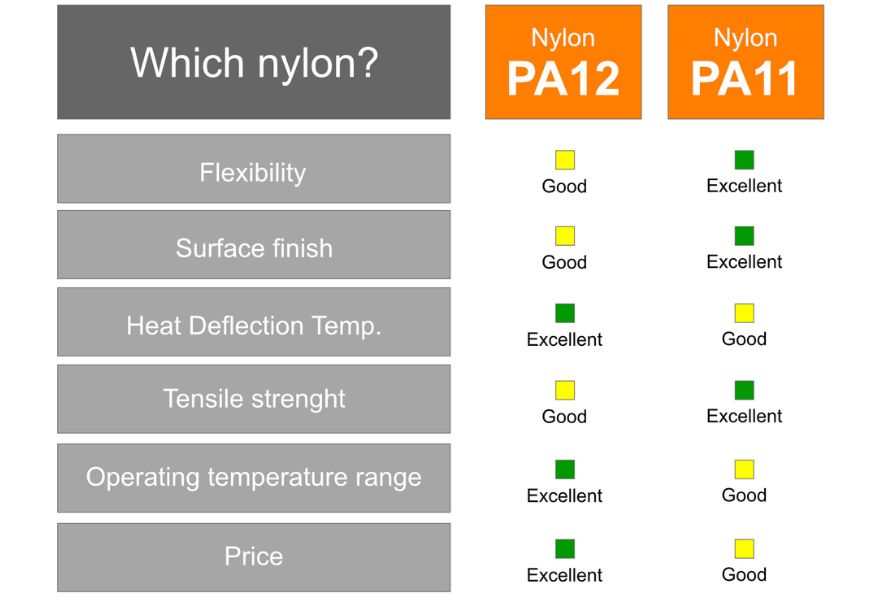

Når man skal vælge mellem Nylon 11 og Nylon 12, er der flere faktorer, der spiller ind. Lad os sammenligne de to materialer på tværs af forskellige parametre for bedre at forstå deres ydeevne.

Mekaniske egenskaber

Nylon 11 har en overlegen slagfasthed og er generelt mere fleksibel, hvilket gør den ideel til anvendelser, hvor sejhed og fleksibilitet er afgørende. Nylon 12 har dog en bedre slidstyrke, hvilket gør det velegnet til anvendelser, der kræver glatte overflader og lav friktion.Kemisk modstandsdygtighed

Nylon 11 udmærker sig ved kemisk modstandsdygtighed, især i miljøer, der udsættes for olier, brændstoffer og skrappe kemikalier. Nylon 12 er stadig holdbart, men klarer sig ikke lige så godt under disse forhold.Termiske egenskaber

Både Nylon 11 og Nylon 12 har god termisk stabilitet, men Nylon 11 har et højere smeltepunkt, hvilket gør det mere velegnet til anvendelser ved høje temperaturer. Nylon 12 giver derimod bedre fleksibilitet ved lave temperaturer.Sammenligning af omkostninger

Nylon 12 er generelt billigere end Nylon 11 på grund af den oliebaserede produktion. Nylon 11's biobaserede natur er godt for miljøet, men bidrager til den højere pris.

Nylon 11 vs. Nylon 12, Hvad er bedst?

Beslutningen om at bruge Nylon 11 eller Nylon 12 afhænger af flere faktorer, herunder de specifikke krav til din anvendelse. Her er nogle vigtige overvejelser:

Faktorer at overveje

- Miljømæssige forhold: Til højtemperatur- og brændstofresistente anvendelser kan Nylon 11 være det bedste valg. Men hvis lav fugtabsorption og dimensionsstabilitet er vigtigere, kan Nylon 12 være at foretrække.

- Omkostningseffektivitet: Nylon 12 er generelt billigere og kan være den bedste løsning til anvendelser med lavere mekaniske krav.

- Miljøpåvirkning: Nylon 11 er mere miljøvenlig på grund af sin biobaserede oprindelse, mens Nylon 12's oliebaserede produktion gør den mindre bæredygtig.

Casestudier af vellykkede anvendelser med hvert materiale

- Nylon 11 i bilindustrien: Brændstofledninger og hydraulikslanger i bilindustrien nyder godt af Nylon 11's modstandsdygtighed over for olier og ekstreme temperaturer, hvilket sikrer lang levetid.

- Nylon 12 tommer medicinsk: På det medicinske område bruges Nylon 12 i vid udstrækning til medicinske slanger, katetre og medicinleveringssystemer på grund af dets lave fugtabsorption og biokompatibilitet.

Konklusion af Nylon 11 vs Nylon 12

Konklusionen er, at både Nylon 11 og Nylon 12 tilbyder forskellige fordele afhængigt af anvendelsen. Nylon 11 skiller sig ud med sin kemiske resistens, slagstyrke og biobaserede sammensætning, hvilket gør den ideel til barske, højtydende miljøer. På den anden side tilbyder Nylon 12 overlegen fleksibilitet, slidstyrke og lavere omkostninger, hvilket gør det til en passende løsning til applikationer, der kræver glat finish og dimensionsstabilitet.

Når du skal vælge mellem disse to materialer, skal du overveje faktorer som omkostninger, miljøpåvirkning og de specifikke krav til ydeevne i dit projekt. Ved at afveje disse overvejelser kan du træffe en informeret beslutning, der opfylder dine funktionelle og budgetmæssige behov.

Ofte stillede spørgsmål om Nylon 11 vs. Nylon 12

Hvad er de største forskelle mellem Nylon 11 og Nylon 12?

Nylon 11 er biobaseret og mere modstandsdygtig over for olier og brændstoffer, mens Nylon 12 har bedre slidstyrke og lavere fugtabsorption.Hvilket materiale er bedst egnet til højtydende applikationer?

Nylon 11 er generelt bedre til højtydende anvendelser, der kræver kemisk modstandsdygtighed og fleksibilitet, især i bil- og luftfartsindustrien.Er det ene materiale mere miljøvenligt end det andet?

Ja, Nylon 11 er mere miljøvenligt, fordi det er fremstillet af ricinusolie, mens Nylon 12 er fremstillet af oliebaserede råmaterialer.

Ved at forstå disse forskelle kan du trygt vælge det rigtige nylonmateriale til dine specifikke behov.