CECHY NYLONU 12

✔ Trwałość

✔ Wysoka wytrzymałość

✔ Odporność chemiczna

✔ Stabilność wymiarowa

✔ Niska absorpcja wilgoci

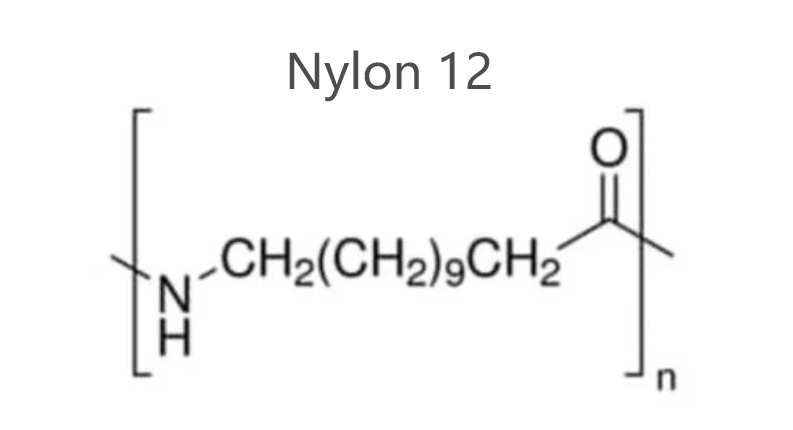

Nylon 12, znany również jako tworzywo PA12, jest wysokowydajnym termoplastycznym tworzywem konstrukcyjnym znanym z wyjątkowego połączenia wytrzymałości, elastyczności i sprężystości. Ten zaawansowany materiał oferuje atrakcyjne rozwiązanie dla szerokiej gamy wymagających zastosowań, co czyni go najlepszym wyborem dla projektantów, inżynierów i producentów poszukujących niezrównanej wydajności.

Niezrównana charakterystyka wydajności:

Korzyści w różnych branżach:

PA12 GF25 to rodzaj tworzywa nylonowego wzmocnionego włóknami szklanymi 25% w celu zwiększenia wytrzymałości i odporności na ciepło.

PA12 GF30 to rodzaj tworzywa nylonowego wzmocnionego włóknami szklanymi 30% w celu zwiększenia wytrzymałości i odporności na ciepło.

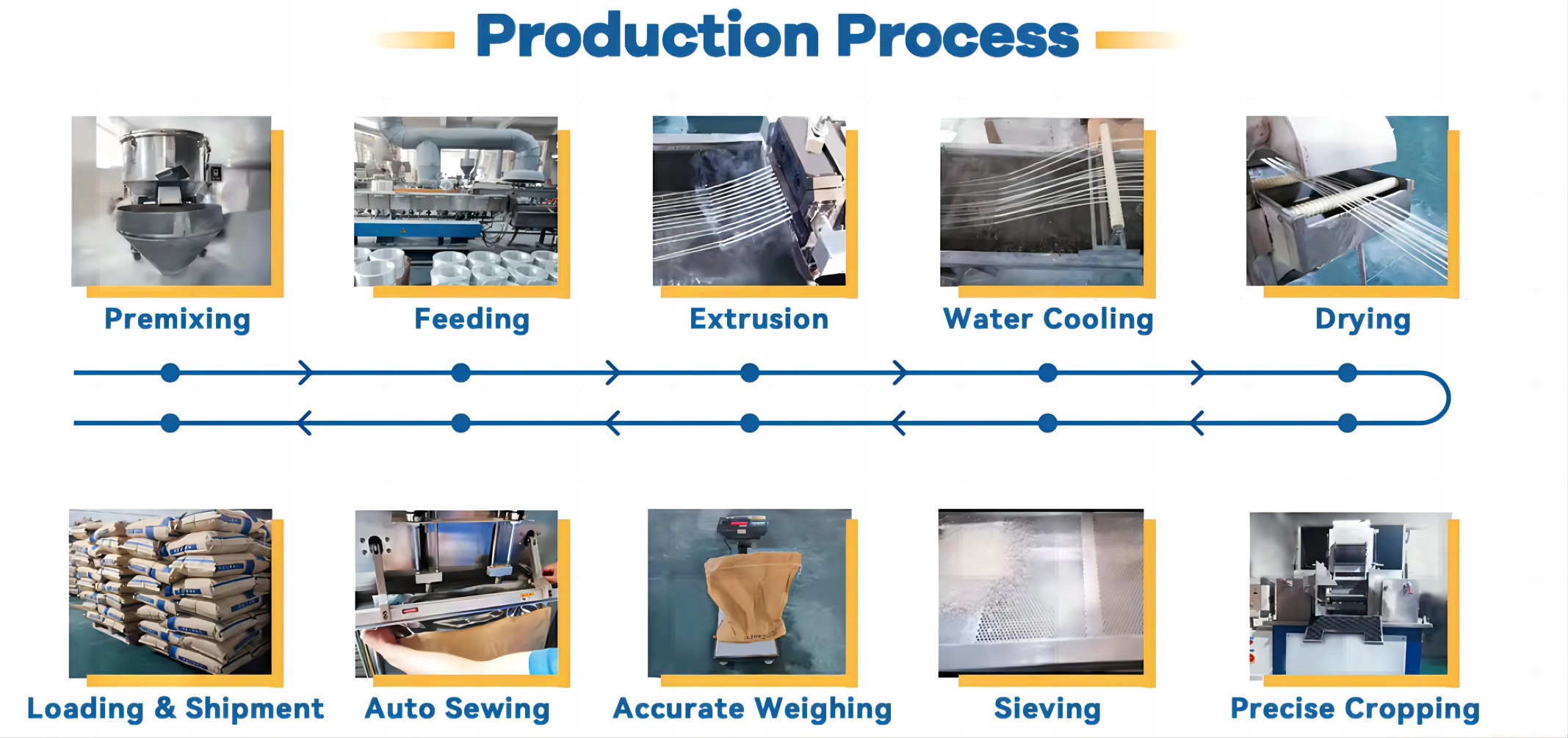

Wysokowydajny nylon PA12 przekształcany w trwałe produkty w ekonomicznym procesie wytłaczania.

Wytłaczanie mieszanki PA12 tworzy mocne, lekkie części poprzez połączenie nylonu PA12 z dodatkami zwiększającymi wydajność.

Nylon 12, znany również jako poliamid 12 (PA12), to rodzaj konstrukcyjnego tworzywa sztucznego znanego ze swojej wytrzymałości, elastyczności i niskiego tarcia.

Nylonowe tworzywo sztuczne ma kilka zalet:

Istnieje wiele rodzajów nylonu, z których każdy ma swoje własne właściwości. Nylon 12 oferuje dobrą równowagę między wytrzymałością, elastycznością i niskim tarciem w porównaniu z niektórymi nylonami, takimi jak Nylon 6 (PA6), które mogą być sztywniejsze. Nylon 6 może jednak oferować lepszą wydajność w wysokich temperaturach.